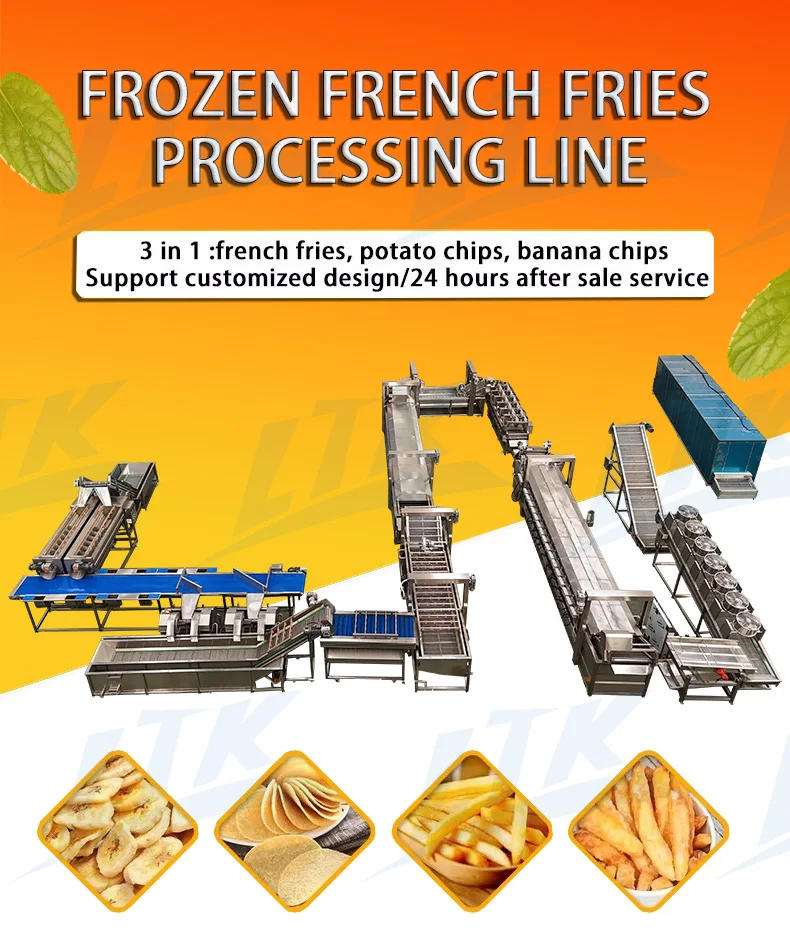

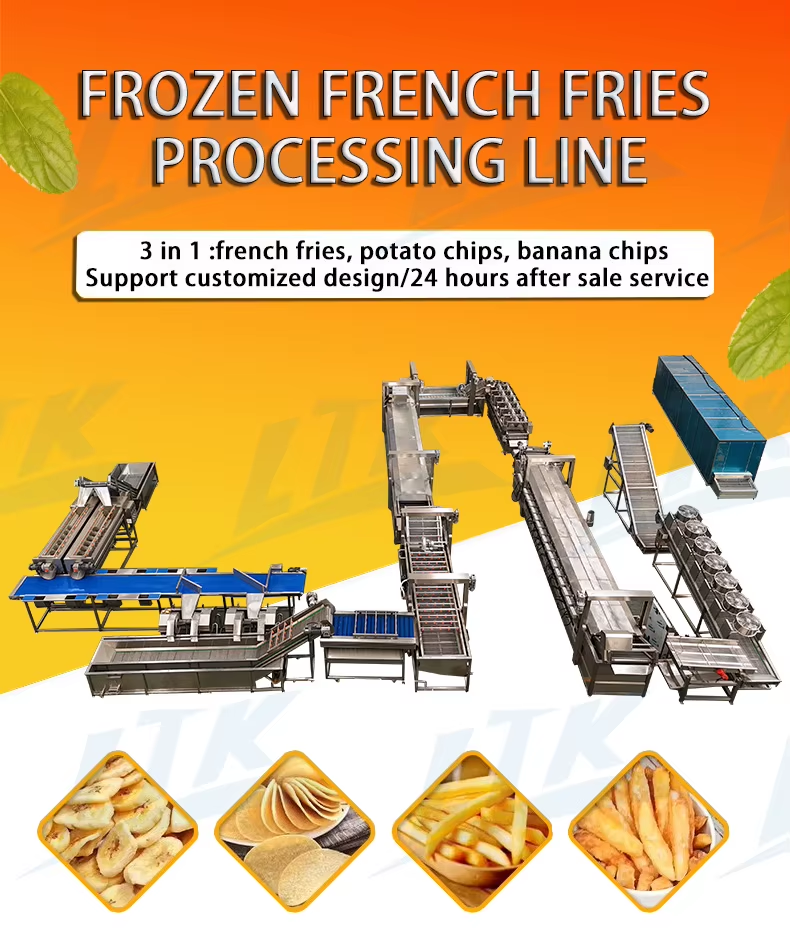

1000kgh New Condition Potato Fruit and Corn Frozen French Fries Production Line for Vegetable Processing Plant

US $40,000.00-60,000.00 / ton

1 ton(s)Minimum order

condition:

New

brand name:

LTK

place of origin:

Shandong, China

voltage:

380v

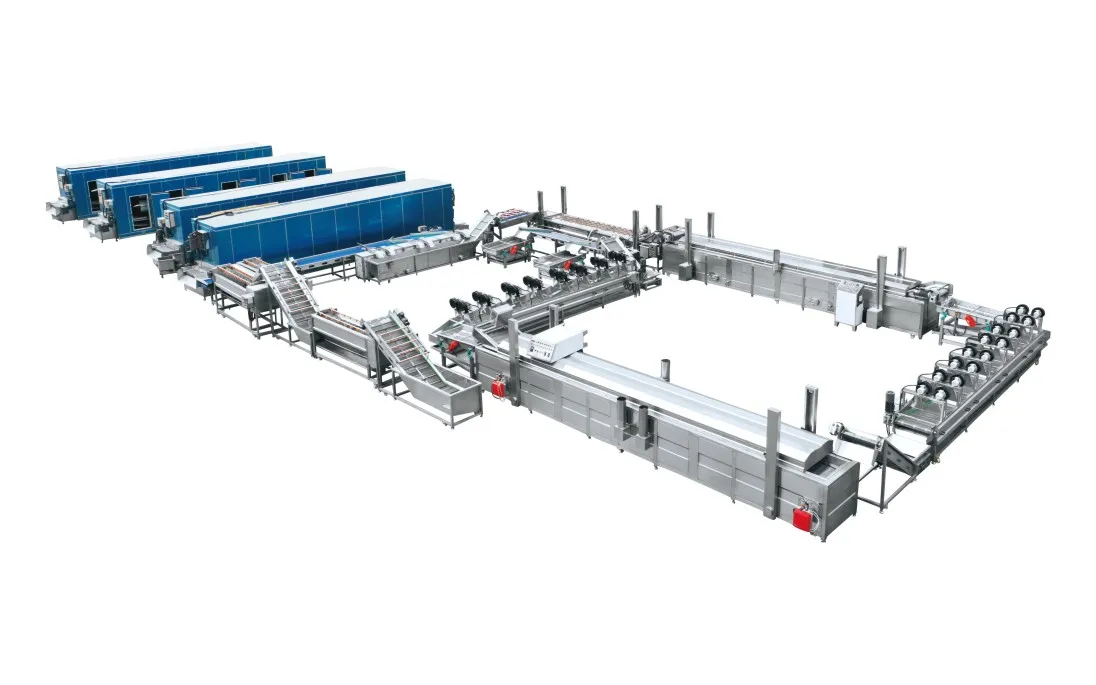

dimension(l*w*h):

90*8*4M

weight:

10000

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| condition | New |

|---|---|

| brand name | LTK |

| place of origin | Shandong, China |

| voltage | 380v |

| dimension(l*w*h) | 90*8*4M |

| weight | 10000 |

| warranty | 1 Year |

| application fields | Vegetable processing plant, Fruit processing plant |

| raw material | Fruit, Vegetables |

| output product name | French Fries |

| key selling points | High Productivity |

| Power | Customized |

| Capacity | 1000kg/h |

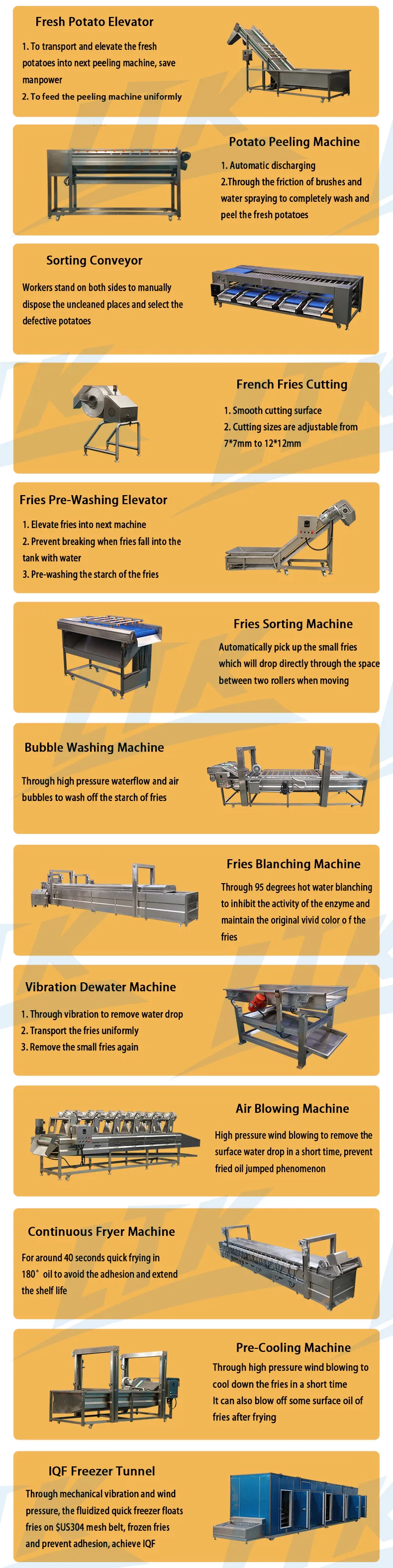

Product Detail

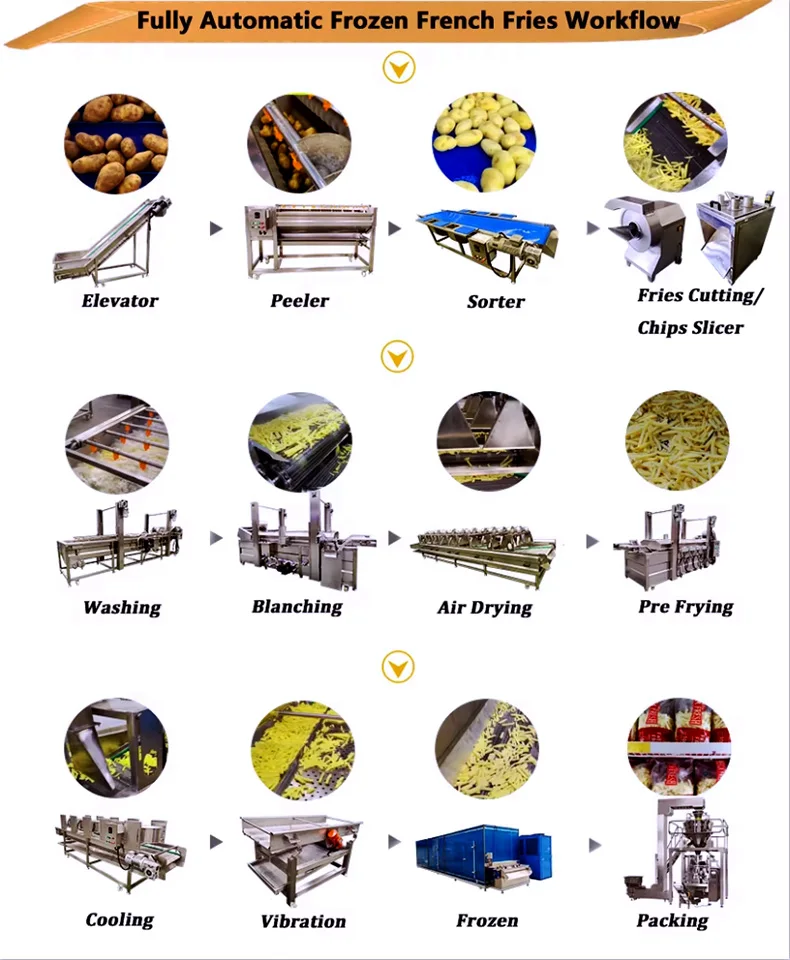

1.Clean

It is mainly divided into two parts: peeling and cleaning. The main equipment is automatic peeling and cleaning machine

and air bubble cleaning machine. After peeling the potato, this step is to clean it again to meet the clean standard.

2.Cut/Slicing

and air bubble cleaning machine. After peeling the potato, this step is to clean it again to meet the clean standard.

2.Cut/Slicing

Cleaning the picked potatoes automatically entered the cutting machine and cut it. The ma-chine absorbs the

advantages of similar products, it has the advantages of reasonable structure, high efficiency, energy -saving consumption, simple operation, etc. The material is uni-form, beautiful, and less consumed

advantages of similar products, it has the advantages of reasonable structure, high efficiency, energy -saving consumption, simple operation, etc. The material is uni-form, beautiful, and less consumed

3.Select

Siege the fries after cutting and eliminate unqualified products

4. Rinse

Wash the surface starch on the fries

5. Blanching

After the rinsing, the fries entered the drifting stage and carried out color protection and sterilization

6. Air -drying

Dry the water remaining on the surface of the french fries on the surface of the hot flies, which can maintain the original shape of the fries to a greater extent.

7. Frying

Use oil and water to separate the fried fryer, with controllable temperature, maintain the original flavor

8. Air -drying

Dry the fried fried fries to avoid the taste and taste of residual oil residue affecting the fries.

9. Frozen

10.Package

Using automatic weighing packaging machines, fast speed and high efficiency.

Product Paramenters

No. | Machine Name | Dimension | Power | Quantity | Material |

1 | PU Belt Elevating Conveyor | 2400*700*1600mm | 0.75kw | 1set | SUS304 |

2 | Potato Washing & Peeling Machine | 3400*1000*1400mm | 4.37kw | 1set | SUS304 |

3 | Sorting Conveyor | 3000*700*900mm | 0.75kw | 1set | SUS304 |

4 | French Fries Cutting Machine | 950*800*950mm | 1.5kw | 1set | SUS304 |

5 | Water Tank Elevator | 2200*800*1600mm | 0.75kw | 1set | SUS304 |

6 | Fries Sorting Machine | 2400*1000*1300mm | 2kw | 1set | SUS304 |

7 | Bubble Washing Machine | 4000*1200*1400mm | 6kw | 1set | SUS304 |

8 | Blanching Machine | 5000*1200*1400mm | 140kw | 1set | SUS304 |

9 | Vibrating Dewatering Machine | 1800*1000*1300mm | 0.36kw | 1set | SUS304 |

10 | Air Drying Machine | 4000*1000*1600mm | 7.5kw | 1set | SUS304 |

11 | Mesh Belt Elevating Conveyor | 2000*800*1300mm | 0.75kw | 1set | SUS304 |

12 | Continuous Frying Machine | 6000*1200*1400mm | 200kw | 1set | SUS304 |

13 | Vibrating Deoiling Machine | 1800*1000*1300mm | 0.36kw | 1set | SUS304 |

14 | Cooling Machine | 4000*1000*1600mm | 7.5kw | 1set | SUS304 |

15 | Mesh Belt Elevating Conveyor | 2000*800*1300mm | 0.75kw | 1set | SUS304 |

16 | IQF Freezer Tunnel | 11500*2200*2200mm | 90kw | 1set | SUS304 |

17 | Elevating Conveyor | 3000*500*1400mm | 1.1kw | 1set | SUS304 |

18 | Automatic Packing Machine | 5000*2000*3400mm | 6.7kw | 1set | SUS304 |

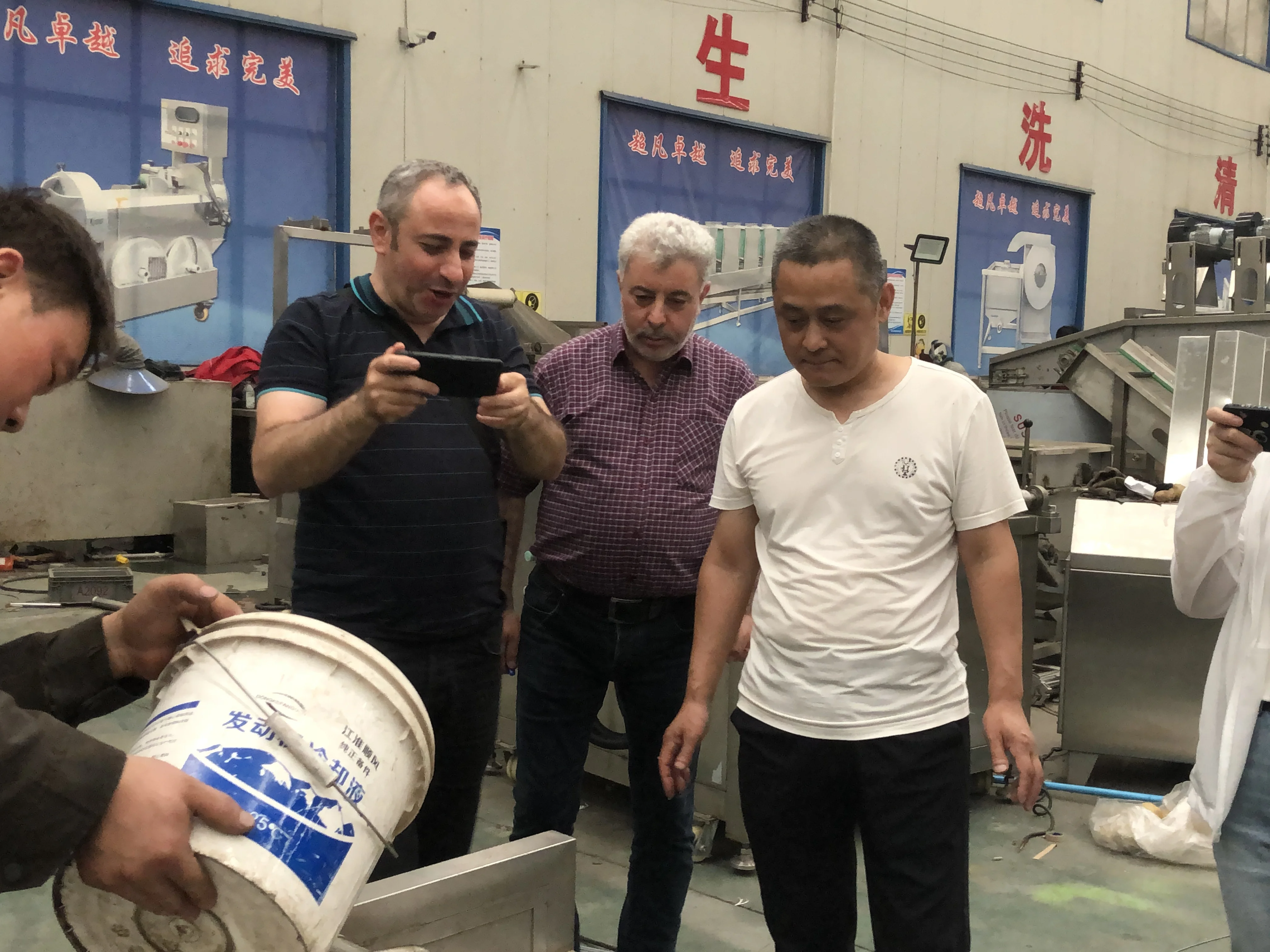

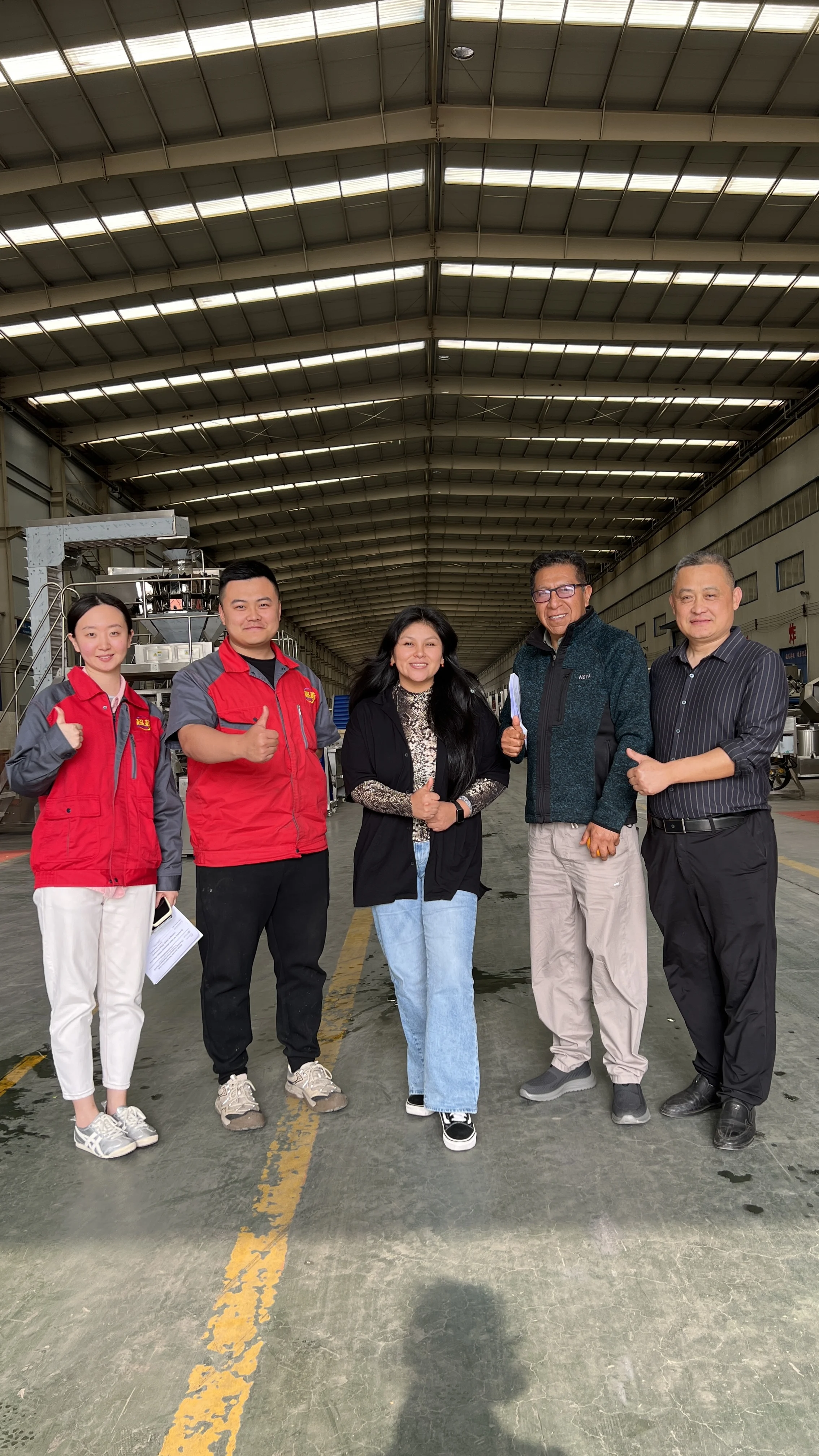

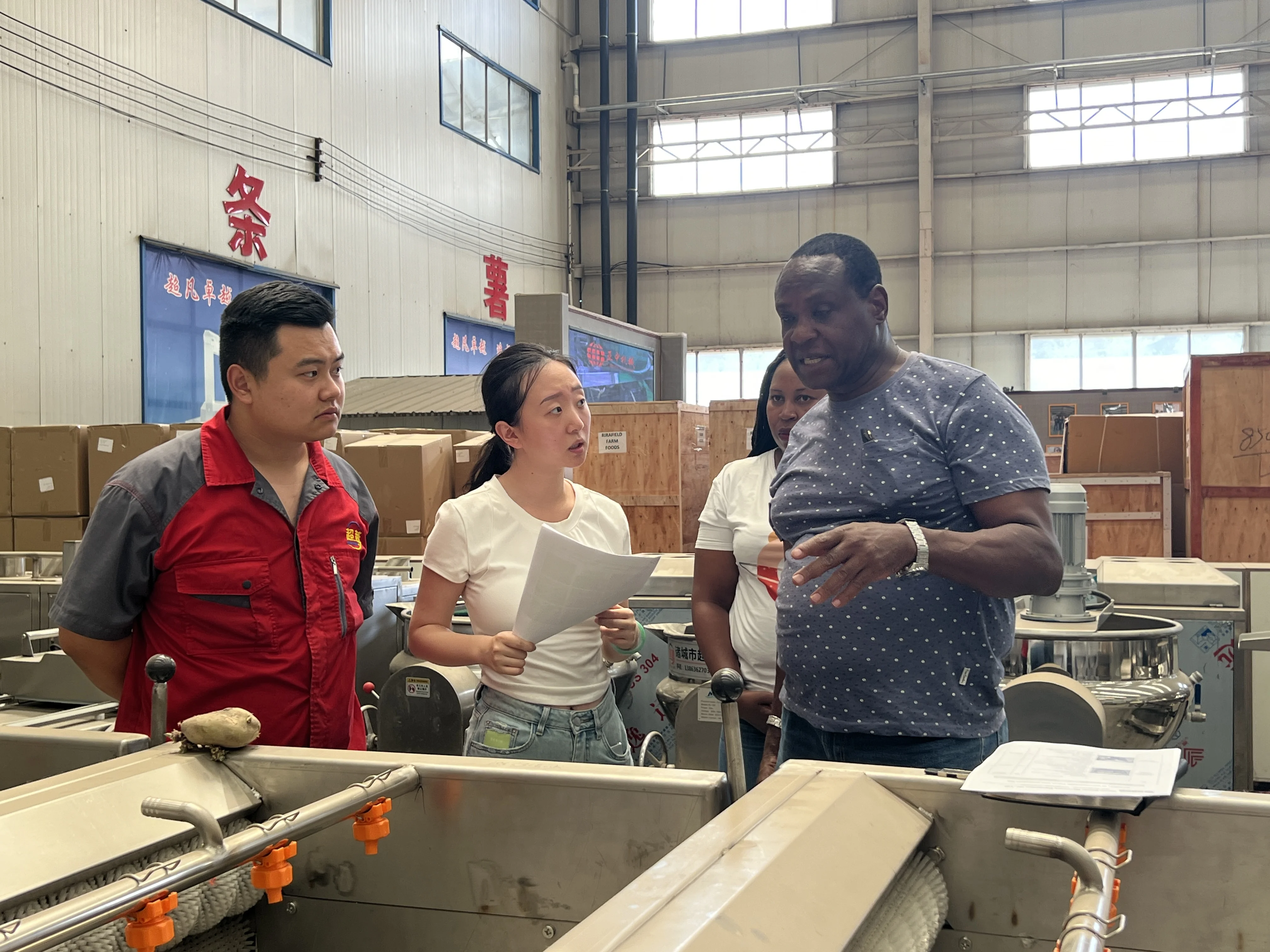

Customer Photos

CUSTOMER CASES

N**A

The design of the equipment is very reasonable, it is comfortable to use, and the service is also very timely.

★★★★★ 5.0 Very Satisfied

Project Site: Panama

Type: 1000kg/h

S****a

LTK is big brand in China on food equipment, i worked with LTK from 2021, i bought many equipment and some already received, quality very good, also after sales service,

Project Site:Germany

Type: 800kg/h

L***y

I like this machine very much,because it support customized and it can give a free brush,it washing and peeling the potatoes well,very clean and not damage the potatoes.

★★★★★ 5.0 Very Satisfied

Project Site:Netherlands

Type: 900kg/h

Project Site:Netherlands

Type: 900kg/h

R**n

Project Site:England

Type: 800kg/h

This machine can produce potato chips efficiently, with good quality and high quality, and the material is SUS304, I like it very much.

★★★★★ 5.0 Very Satisfied

★★★★★ 5.0 Very Satisfied

Project Site:England

Type: 800kg/h

FAQ

A1: We are a source factory and we equipped with SGS factory inspection report.

Warmly welcome to visit our factory if you have a travel plan.

Q2: How can I make sure your machine is suitable for my products?

A2: We will provide working videos for reference or show you online by video chatting.

If possible, you can also send us your products and we will test on our machine.

Q3: How can I trust you for the first time business?

A3: You can check our full range of business licence and certificates.

And we suggest Alibaba Trade Assurance for all transactions to protect your money.