10cbm lpg Cooking Gas Auto Filling Station Gas Station lpg Filling Plant for South Africa

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Shandong, China |

|---|---|

| brand name | CJSE |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | Pressure vessel |

| dimension(l*w*h) | 9.5 x 2 x 2.3m |

| volume (m³) | 5 - 200 |

| inner material | Q345R |

| outer material | Q345R |

| Design Pressure (mpa) | 1.77 |

| design standard | GB150/ASME |

| working temperature(℃) | -19 - 50 ℃ |

| warranty | 1 Year |

| key selling points | Long Service Life |

| LPG Tank Type | mobile skid mounted lpg filling station 10KL lpg gas skid station |

| LPG Tank Working Pressure | 1.63MPa |

| LPG Tank Design Pressure | 1.77MPa |

| LPG Tank Materials | Q345R carbon steel |

| LPG Tank Length | 9334mm |

| LPG Tank Standard | GB150/ASME |

| LPG Tank Color | netural grey or silver |

| Capacity Available for tank | 5m3 to 200m3 LPG Filling Plant 5 Ton |

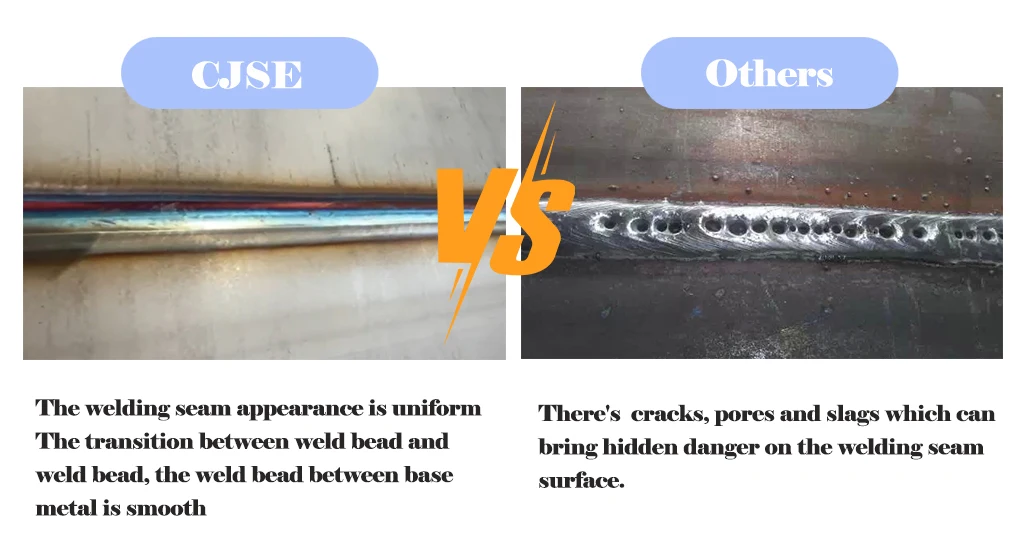

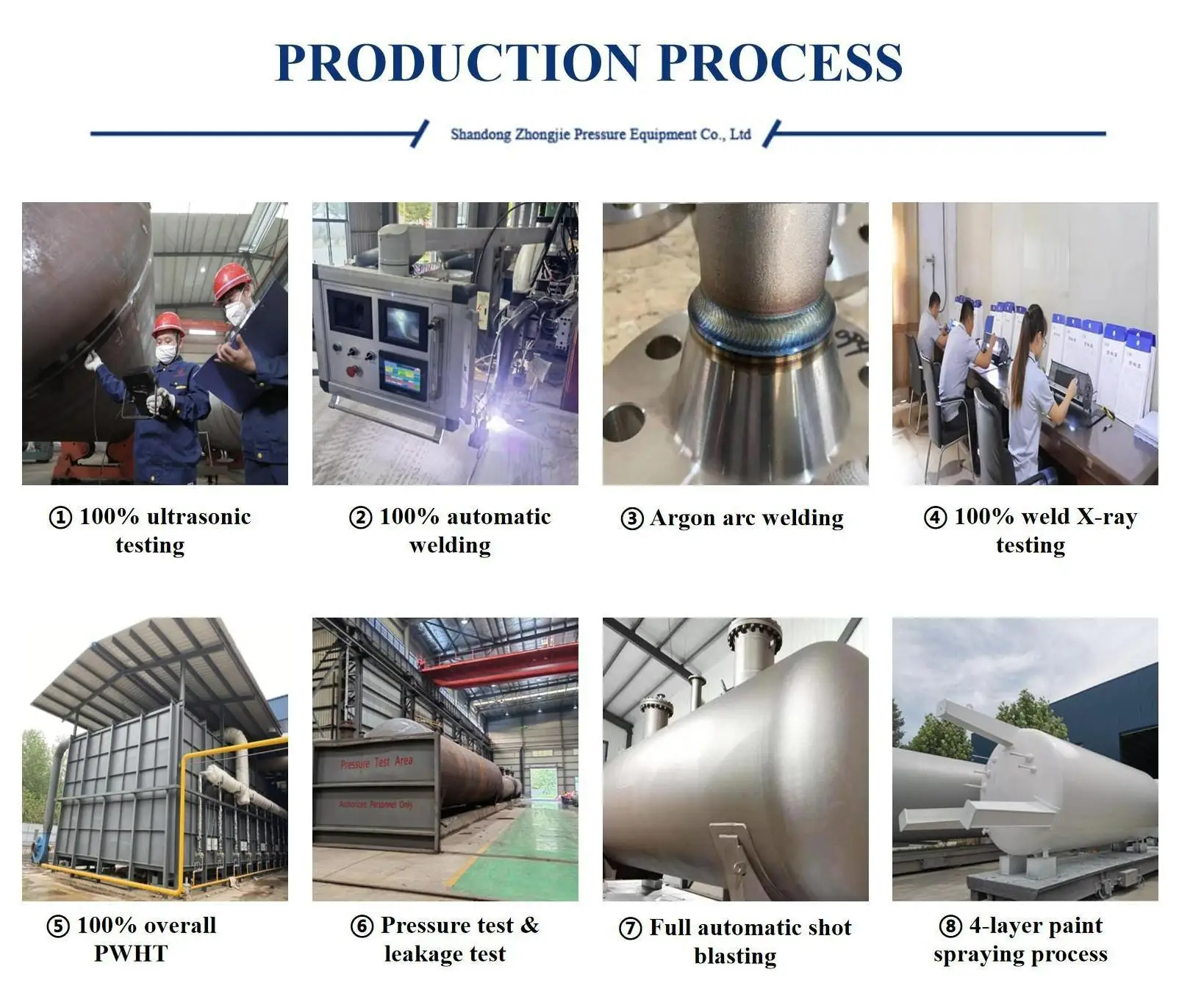

| Processing for LPG Tank | heat treatment/shot blast/X-ray detection |

| LPG Tank Applications | for lpg storage |

| Condition | New |

| Warranty of core components | 1 Year |

| Applicable Industries | Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Printing Shops, Construction works , Other, Advertising Company |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Russia, Spain, Kenya, South Korea, Chile, Colombia, Romania, South Africa, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia, Morocco |

| Capacity | 5 - 200 |

| Marketing Type | New Product 2022 |

| Max Working Pressure(MPa) | 1.82 |

| Weight | 2765 |

Product Detail

Data | |

LPG storage tank capacity | 5-200 cbm (2.5-100 ton) |

Design Pressure | 1.77Mpa |

Working Pressure | 1.63Mpa |

Working Temperature | -19~50℃ |

Design Temperature | -20~54℃ |

Main Material | Q345R |

Filling ratio | 0.9 |

Density | 560 kg/m3 |

Design Service Life | 20 Years |

PWHT | Whole |

available for online troubleshooting and developing maintenance plan, 100% troubleshooting rate guaranteed.

guarantee 100% project delivered on time.