12 Zones PCB Soldering Station SMT Automatic Welding Machine Hot Air Reflow Oven NeoDen IN12C with TUV CE and 2 Years Warranty

1 set(s)Minimum order

condition:

New

type:

Reflow Solder

place of origin:

Zhejiang, China

brand name:

NEODEN

usage:

pcb making

voltage:

220v

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| condition | New |

|---|---|

| type | Reflow Solder |

| place of origin | Zhejiang, China |

| brand name | NEODEN |

| usage | pcb making |

| voltage | 220v |

| warranty | 2 years |

| weight (kg) | 300 KG |

| Heating Method | Hot Wind |

| Heating Zones | Upper6/down6 |

| Language | English/Chinese |

| Applicable Industries | Machinery Repair Shops, Other |

| Showroom Location | United Kingdom, United States, Italy, France, Germany, Brazil, Pakistan, India, Russia, South Korea, Chile, Colombia, Ukraine, Australia |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 2 years |

| Core Components | PLC, Engine, motor |

| Key Selling Points | Low Maintenance Cost |

Product Detail

12 Zones PCB Soldering Station SMT Automatic Welding Machine Hot Air Reflow Oven NeoDen IN12C

Product Description

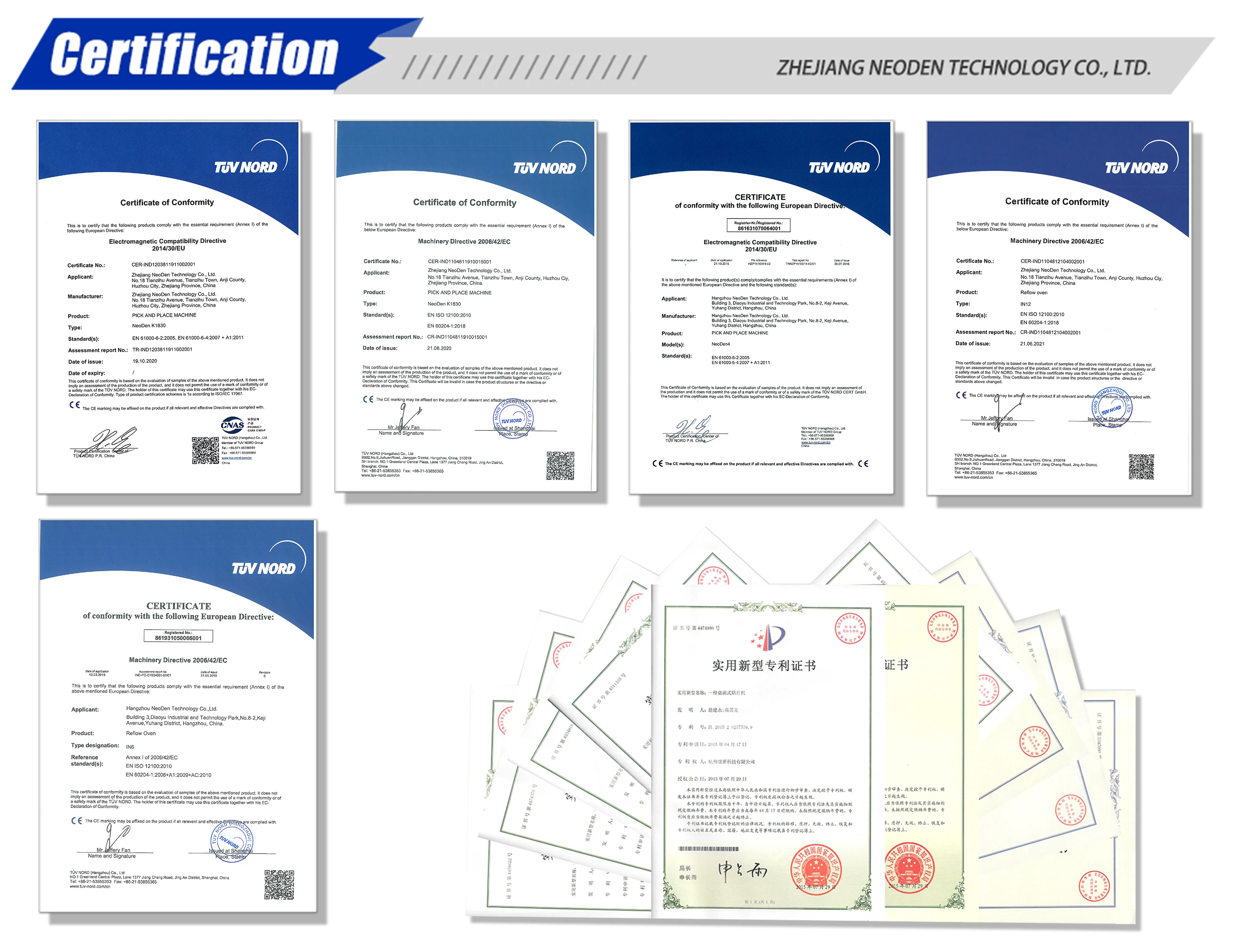

NeoDen IN12C is a new environmentally friendly, stable performance intelligent automatic orbital reflow soldering. This reflow solder adopts the exclusive patented design of "even temperature heating plate" design, with excellent soldering performance; with 12 temperature zones compact design, lightweight and compact; to achieve intelligent temperature control, with high-sensitivity temperature sensor, with stable temperature in the furnace, the characteristics of small horizontal temperature difference; while using Japan imported hot air motor bearings and Switzerland imported Heating wire, durable and stable performance. And through the CE certification, to provide authoritative quality assurance.

Specification

Model | NeoDen IN12C | ||||||

Heating Zone Quantity | Upper6 / Down6 | ||||||

Cooling Fan | Upper4 | ||||||

Controller | VGUS Microcomputer | ||||||

Transmission | Rail | ||||||

Heating Type | Nichrome Wire & Aluminum Alloy Heating | ||||||

Conveyor Speed | 50~600 mm/min | ||||||

Temperature Range | Room temperature~300ºC | ||||||

Temperature Accuracy | 1ºC | ||||||

PCB Temperature Deviation | ±2ºC | ||||||

Max Soldering Width (PCB Width) | 300mm | ||||||

Heat-up Time | 30 min | ||||||

Max Soldering Height (mm) | Upper 30mm Down 15mm | ||||||

Operation Direction | left→right | ||||||

Electricity Supply | AC 220v/single phase | ||||||

Starting Power | 2.2kw~4.8kw (adjustable) | ||||||

Typical Working Power | approx. 2kw(1.5mm fiberglass PCB ) | ||||||

Machine Size | L2305*W612*H1230 | ||||||

Net Weight | 300KGS | ||||||

Gross Weight | 414KGS | ||||||

Features

1. Built-in welding fume filtration system, effective filtration of harmful gases.

2. Unique heating module design, with high precision temperature control, uniform temperature distribution in the thermal

compensation area, high efficiency of thermal compensation, low power consumption.

3. Hot air convection, excellent welding performance.

4.The use of high-performance aluminum alloy heating plate instead of heating tube.

5.The heat insulation protection design, the shell temperature can be effectively controlled.

6. Integrated with the PID control algorithm of the custom-developed intelligent control system.

7. Professional unique 4-way board surface temperature monitoring system, so that the actual operation in a timely and

comprehensive feedback data, even for complex electronic products can be effective.

8. Up to 4-way real-time display of PCB board surface welding temperature curve.

9. Custom-developed track drive motor according to the characteristics of the B-type mesh belt, to ensure uniform speed and long life.

10. Independent circulating air design of the cooling area, completely isolated from the external environment on the internal temperature cavity.

11. The control system uses imported chips, temperature control accuracy of ± 0.5%.

12. All temperature zones and cold air zone wind speed adjustable, easily cope with a variety of welding needs.

2. Unique heating module design, with high precision temperature control, uniform temperature distribution in the thermal

compensation area, high efficiency of thermal compensation, low power consumption.

3. Hot air convection, excellent welding performance.

4.The use of high-performance aluminum alloy heating plate instead of heating tube.

5.The heat insulation protection design, the shell temperature can be effectively controlled.

6. Integrated with the PID control algorithm of the custom-developed intelligent control system.

7. Professional unique 4-way board surface temperature monitoring system, so that the actual operation in a timely and

comprehensive feedback data, even for complex electronic products can be effective.

8. Up to 4-way real-time display of PCB board surface welding temperature curve.

9. Custom-developed track drive motor according to the characteristics of the B-type mesh belt, to ensure uniform speed and long life.

10. Independent circulating air design of the cooling area, completely isolated from the external environment on the internal temperature cavity.

11. The control system uses imported chips, temperature control accuracy of ± 0.5%.

12. All temperature zones and cold air zone wind speed adjustable, easily cope with a variety of welding needs.

Detailed Pictures

1. Custom-developed track drive motor according to the characteristics of the B-type mesh belt, to ensure uniform speed and long life.

SMT Line

Related Products

About Us

「About NEODEN」

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one-stop SMT equipment.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

FAQ

Q1: Do you provide software updates?

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air supply?

We have vacuum pumps inside the machine, it does not need air supply.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We have English user manual and guide video to teach you how to use the machine. If you still have question, pls contact us by email/skype/phone etc for online service.

Q4: How about the warranty?

We have 2 years warranty for NeoDen4, K1830, NeoDen9, In6, IN12 and 1 year for all other models with lifetime after-sale support.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air supply?

We have vacuum pumps inside the machine, it does not need air supply.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We have English user manual and guide video to teach you how to use the machine. If you still have question, pls contact us by email/skype/phone etc for online service.

Q4: How about the warranty?

We have 2 years warranty for NeoDen4, K1830, NeoDen9, In6, IN12 and 1 year for all other models with lifetime after-sale support.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

If you have any questions, welcome to contact us!