1300mm Automatic Single Side Extrusion Lamination PE Coating Paper Machine

US $28,900.00 / set

1 set(s)Minimum order

Product Type:

Paper Bag Making Machine

processing type:

Laminating Machine

place of origin:

China

voltage:

380V

warranty:

1 Year

production capacity:

200 pcs/min

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Product Type | Paper Bag Making Machine |

|---|---|

| processing type | Laminating Machine |

| place of origin | China |

| voltage | 380V |

| warranty | 1 Year |

| production capacity | 200 pcs/min |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, Engine, PLC, Pump, Gear |

| Weight (KG) | 3500 |

| The project name | Bag lamination machine |

| The motor power | 22kw |

| Raw material | Paper ,woven bag |

| Model | DD800 |

| Production | 50-300m/min |

| PLC | Siemens |

| The extruder machine heating way | Electrical heating |

| Tension control | Including |

| The unwinding diameter | 1200mm |

| The machine color | standard or customized |

Product Detail

Product Overview

Extrusion Coating Lamination Machine

1.Feature:

1.T-Die : it applies to high precision Hanger-type.Width of lamination is adjustable.

2.The Unwinding Device,Laminating Device and Rewinding Device synchronized auto control.

3.Large diameter Auxiliary Unwinding Device, suit for laminate various types of substrate.

4.Automatic Roller Changing Device,chang rolls without stopping the machine.

5.The whole machine is PLC computerized control.

6.Equipped with Corona Treatment, Automatic Edge Trimming Device, Production Quantity Calculate,and Adjustable Edge Cutting.

7.Appear of new design structure,nice exterior,easy of installation as well as operation.

1.T-Die : it applies to high precision Hanger-type.Width of lamination is adjustable.

2.The Unwinding Device,Laminating Device and Rewinding Device synchronized auto control.

3.Large diameter Auxiliary Unwinding Device, suit for laminate various types of substrate.

4.Automatic Roller Changing Device,chang rolls without stopping the machine.

5.The whole machine is PLC computerized control.

6.Equipped with Corona Treatment, Automatic Edge Trimming Device, Production Quantity Calculate,and Adjustable Edge Cutting.

7.Appear of new design structure,nice exterior,easy of installation as well as operation.

Our Advantages

The Extrusion Laminating Machine takes LDPE,HDPE,PP, etc. resin as raw material. It processes by melting the plastic

particles,extruding from the T-Die and finally laminating with the base material. This type of machine has been widely used for the lamination of substrates such as white cardboard paper,kraft paper, non woven fabric,woven fabric,aluminum foil, gauze, etc.The finished product was famous for its high fastness,uniformity of thickness and high efficiency.AII these have contribute to make this type of machine become one of the most popular and valuable extrusion laminating machine at home and abroad.

particles,extruding from the T-Die and finally laminating with the base material. This type of machine has been widely used for the lamination of substrates such as white cardboard paper,kraft paper, non woven fabric,woven fabric,aluminum foil, gauze, etc.The finished product was famous for its high fastness,uniformity of thickness and high efficiency.AII these have contribute to make this type of machine become one of the most popular and valuable extrusion laminating machine at home and abroad.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

No | Item | Data | ||||||||

1 | Model | DD-800 | DD-1000 | DD-1200 | DD-1600 | DD-1800 | ||||

2 | Max coating width | 800mm | 1000mm | 1200mm | 1600mm | 1800mm | ||||

3 | Extruding power | 25kw | 30kw | 37kw | 37kw | 45kw | ||||

4 | Extruding screw | 80mm | 90mm | 95mm | 100mm | 110mm | ||||

5 | Max output | 160kg/h | 180kg/h | 220kg/h | 240kg/h | 260kg/h | ||||

6 | Coating resin | LDPE ,HDPE, PP | ||||||||

7 | Base material | Paper (35-350g/m),Non-woven fabric, Woven cloth,Aluminum foil | ||||||||

8 | Machine speed | 80-150m/min | ||||||||

9 | Coating thickness | 0.012mm-0.05mm | ||||||||

10 | Diameter of unwinding | 1200mm-1500mm | ||||||||

11 | Diameter of rewinding | 1200mm-1500mm | ||||||||

12 | Electric controller mode | PLC programmable controller, touch screen operation | ||||||||

13 | Installing area | 13000mm*9000mm*3000mm | ||||||||

PRODUCT CONFIGURATION

Certifications

Why Choose Us

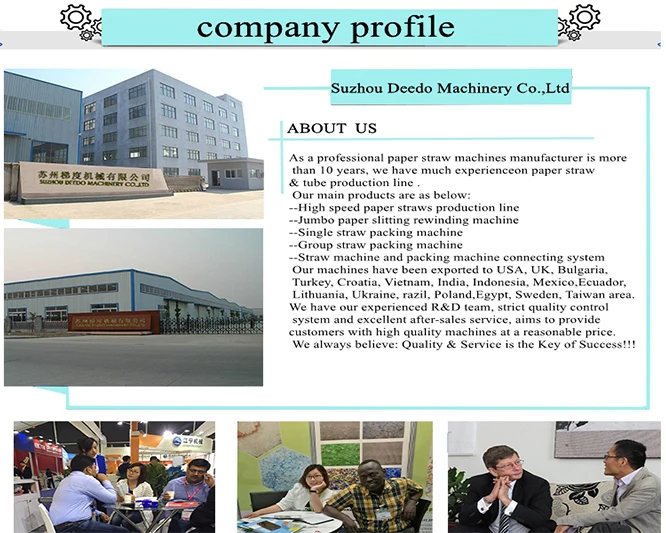

DEEDO Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, DEEDOMachinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.DEEDO Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, DEEDO Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

Thanks to the R&D ability and well-understanding industries experience, DEEDOMachinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.DEEDO Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, DEEDO Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to DEEDO Machine site

● The meaning of visiting supplier, because seeing is believing, DEEDO Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE DEEDO MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 20 years

●After all the equipment are completed, we will connect all the machines and run the full production line to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF DEEDO MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers e-mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

3HOW CAN I GET SPARE PARTS FOR REPLACEMENT IN OTHER COUNTRIES?

●Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent if you want to know more details about DEEDO machine ,welcome to send us an inquIry now !

HOW DO YOU ASSISTANT TO INSTALL THE MACHINE ON WORKSITE?

●We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation,

commissioning.

●We are experienced on turn-key project, engineer and technicians will assistant client on construction, installation,

commissioning.

3HOW CAN I GET SPARE PARTS FOR REPLACEMENT IN OTHER COUNTRIES?

●Wearing parts like blades, it is necessary to buy with machine, other parts in stock could be delivery out by express if urgent if you want to know more details about DEEDO machine ,welcome to send us an inquIry now !