200-300 Mesh Discharge Small Roll Mill Graphite QM-5/15 Mini Lab Ball Mill with PU Roll Mill Jar+Zirconia/Agate Ball

US $600.00-680.00 / set

1 set(s)Minimum order

output (kg/h):

35 - 350 kg/h

feeding size (mm):

0 - 3 mm

output size (mesh):

0 - 300 mesh

application:

Mineral Processing

type:

Ball Mill

place of origin:

Jiangxi, China

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| output (kg/h) | 35 - 350 kg/h |

|---|---|

| feeding size (mm) | 0 - 3 mm |

| output size (mesh) | 0 - 300 mesh |

| application | Mineral Processing |

| type | Ball Mill |

| place of origin | Jiangxi, China |

| brand name | wkd |

| weight (kg) | 32 KG |

| warranty | 1 Year |

| key selling points | Energy saving |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor |

| Product name | Lab Roll Ball Mill |

| Feeding Size | 1-10mm |

| Discharge Size | 300-500mesh |

| Range of Spindle Speed(r.p.m) | 60-570 |

| Product Type | Powder Grinding |

| Applicable Industries | Energy & Mining, Other, Construction works , Energy & Mining |

| Application | Metallurgy |

| Single Jar Max Loading | 35kg |

| Installation | Engineer's Guide |

| Pay Terms | TT,Credit Card, Westurn Union,PayPal |

| Condition | New |

| Showroom Location | Viet Nam, Saudi Arabia, South Africa, Kazakhstan, Kyrgyzstan, Tajikistan |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

Product Detail

Product Overview

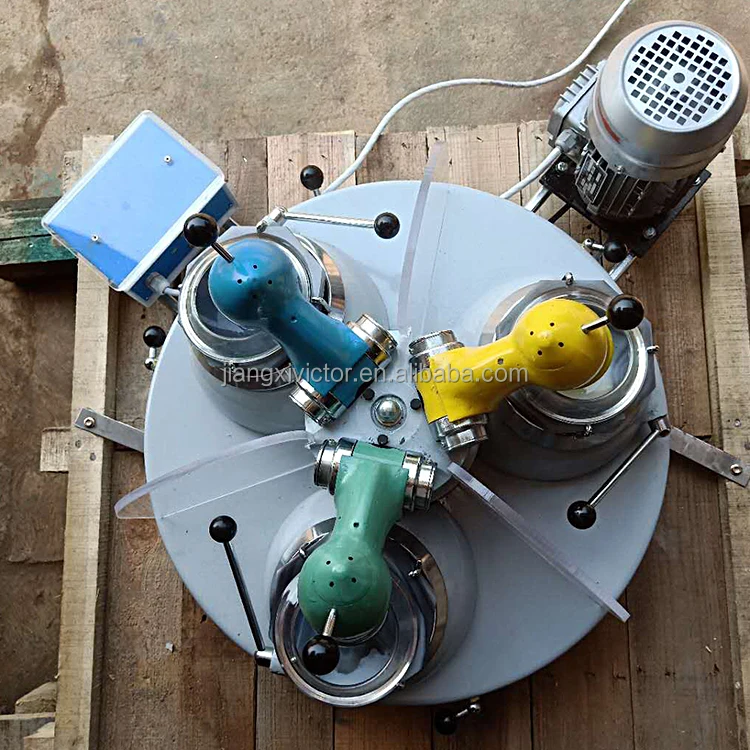

Laboratory Roll Ball Mill

Lab roll mill is a kind of equipment used for ultra-fine grinding and mixing for laboratory and small batch production. The machine is preferred equipment for scientific research, education, experiment and production due to its advantages such as elegant and fashion design, compact structure, easy operation, high efficiency, and uniform granularity. It is widely applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials, and etc.

FEATURES AT A GLANCE

Features

1. Compact structure, easy operation

2. High efficiency and uniform granularity

3. Milling pot in different size can be put on the driven rubber roller within a certain range by means of adjusting space between the rubber rollers.

4. It is convenient to change pots and suitable for both wet and dry grinding.

Work Operational Principle

When mill works, the grinding media and the materials inside the tank are rotated to a certain height. Due to the gravity, they fall down from the tube wall. Materials are crushed by impact action of the grinding media, friction and shearing action of grinding media’s rolling and sliding.

References for Matched Mill Jars and Balls

Our factory provides all kinds of mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

PRODUCT SPECIFICATIONS

Item No. | QM-5 | QM-15 |

Dimension (mm) | 730*415*260 | 845*435*270 |

Weight (kg) | 32 | 43 |

Specifications of Motor | Y0.37-4B3 | Y0.75-4B3 |

Specifications of Frequency Inverter | 0.4kw/220V | 0.75kw/220V |

Range of Rotation Speed (rpm) | 60-570±10 | 60-570±10 |

Valid Length of Roller (mm) | 260 | 340 |

Adjustable Space Between Rollers | 120 | 140 |

Max Load for Single Jar | 35 | 80 |

Details Images

SIMILAR PRODUCTS

Company Profile

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

We are expert especially at mining separating and lab mining plant, main products as below:

FAQ

1.How is the quality of your products? (mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every

grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our

price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice;Finished

product pictures will provide to customers before delivery.

Our Service:

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed

process, and complete process of export

3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available

at any time if you need.

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every

grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our

price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice;Finished

product pictures will provide to customers before delivery.

Our Service:

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed

process, and complete process of export

3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available

at any time if you need.