2000L 2500L 3000L 5000L 10000L Malt Miller for Micro Beer Brewery Equipment Barley Malting Equipment Beer Making Machine Price

US $29,000.00-30,000.00 / set

1 set(s)Minimum order

processing:

Fermenting Equipment

place of origin:

Shandong, China

brand name:

METO

processing types:

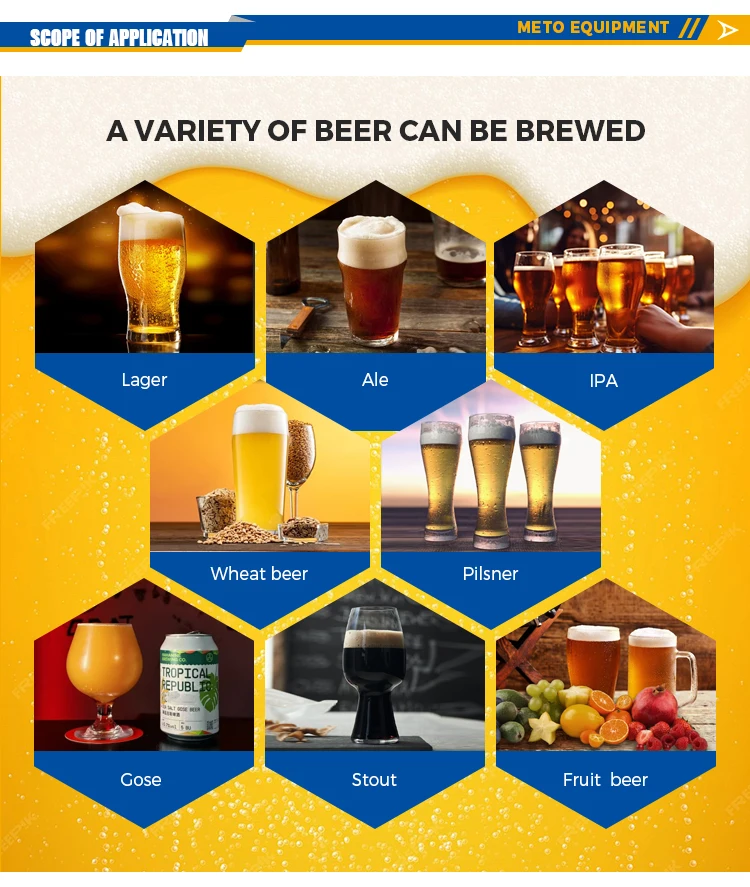

Beer

voltage:

220V/380V/Adjustable

power(w):

15-70Kw Depends

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| brand name | METO |

| processing types | Beer |

| voltage | 220V/380V/Adjustable |

| power(w) | 15-70Kw Depends |

| dimension(l*w*h) | Depends on equipment |

| weight | 5000 |

| warranty | 5 years |

| Machinery Capacity | 1000L, 2000L, 3000L, 3500L, 4000L, 5000L, 10000L |

| machinery test report | Provided |

| core components | motor, Pump, PLC, Bearing |

| key selling points | Easy to Operate |

| video outgoing-inspection | Provided |

| Material | SUS304/SUS316 |

| Welding | Arc Argon Protection |

| Technology | Offer Auto Cad and 3D design drawing |

| Material Thickness | Inner: 4MM Outer:2mm |

| Application | beer factory,brewery system,commercial beer brewing equipment |

| Brewhouse heating | Steam jacket |

| Cooling Unit | Chiller with Glycol Tank |

| Control Unit | HMI , PLC or touching screen |

| Polish Finish | 0.4-0.6um |

| Name | beer brewery equipment |

Product Detail

Products Description

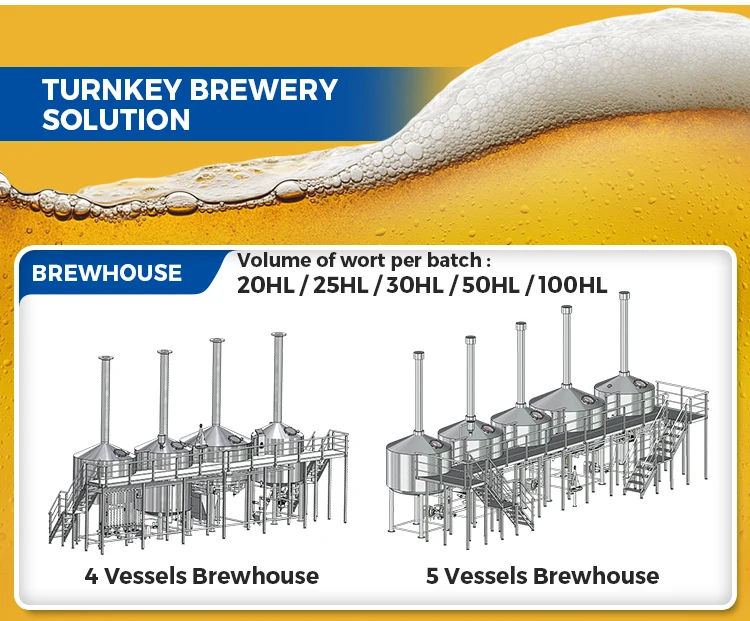

Capacity:

Volume of wort per batch 20HL - 100HL

Volume of wort per batch 20HL - 100HL

Wort / Brew | 20HL | 25HL | 30HL | 50HL | 100HL | ||||

Bach / Day | 2-8 | 2-8 | 2-8 | 2-8 | 2-8 | ||||

Output / Year | 1200KL-4800KL | 1500KL -6000KL | 1800KL - 7200KL | 3000KL-12000KL | 6000KL-24000KL | ||||

Brewhouse Combination | 4 Vessels: Mash tun + Lauter Tun + Boiling Kettle + Whirlpool Tank 5 Vessels: Mash Tun +Prerun Tank + Lauter Tun + Boiling Kettle + Whirlpool Tank Other combinations can be customized on request | ||||||||

Brewery Area Request | >800M² | >1000M² | >1000M² | >1500M² | >2500M² | ||||

Degree of Automation | Full Automatic | Full Automatic | Full Automatic | Full Automatic | Full Automatic | ||||

Brewmaster | 1-2 | 1-2 | 1-2 | 2-3 | 2-3 | ||||

Product advantages

1. Customized design tailored to meet customer's product specifications2. Utilization of top-notch processing equipment and high-caliber production personnel

3. Utilization of stainless steel plates, pump valves, and other accessories sourced from reputable manufacturers

4. Consistent, dependable, and efficient automation control

5. Sleek and sophisticated appearance design with user-friendly operational layout

6. Proven success with numerous domestic brewing industry leaders

7. Exceptional after-sales support

8. Energy-efficient operations to enhance product competitiveness

9. Comprehensive consultation services for beer plant design

Meto offer one-stop turnkey projects. Our commercial brewing equipment are available with several options to help deliver

brewingefficiency, control & automation, and overall flexibility. The brewery combines our engineering expertise and experience

withprecision manufacturing techniques. All systems are expandable and fully customizable based on your requirements.

brewingefficiency, control & automation, and overall flexibility. The brewery combines our engineering expertise and experience

withprecision manufacturing techniques. All systems are expandable and fully customizable based on your requirements.

Commercial Brewery Equipment Component

Malt Milling Unit | Malt Miller, Stainless Steel Conveying, Stainless Steel Conveying, Grist Hydrator,Dusty Collector,Grist Silo, Wet Malt Miller (Option) |

Brewhouse Unit | 3 vessels ,4 vessels ,5 vessels |

Fermentation Unit | 20HL -1000HL |

Water Tank Unit | Hot Water Tank, Cold Water Tank, Ro Water Tank, Hot / Cold / Ro Water Pump |

Cooling Unit | Glycol Water Tank, Chillers, Cooling Pipeling |

Cip Unit | Hot Alkali Tank, Acid Tank, Acid Tank, Sterile Water Tank, Liquid Transfer |

Brewery Control Unit | Brewery Automatic Control System |

Brewery Pipeline Gallery Unit | Wort Pipeline , Wort Pipeline, Beer Pipeline, Cip Pipeline, Co2 Pipeline, Air Compressor Pipeline, Sewage Pipeline, Outdoor Exhaust Pipeline, Steam Pipeline |

Beer Pipeline | |

Cip Pipeline | |

Co2 Pipeline | |

Air Compressor Pipeline | |

Sewage Pipeline | |

Outdoor Exhaust Pipeline | |

Steam Pipeline | |

Square Tube Bracket | |

Other Auxiliary System | Steam Boiler, Ro Water Treatment System, Air Compressor System Centrifugal Filter Machine , Beer Instant Sterilizer Machine (Option) Yeast Propagation Unit (Option), Deoxygenated water systems (Option), Highly concentrated dilution systems(Option) |

Ro Water Treatment System | |

Oil-Free Air Compressor System | |

Yeast Propagation Unit | |

Hop Gun | |

Centrifugal Filter Machine | |

Beer Instant Sterilizer Machine | |

Tube Heat Exchangers | |

Beer Packaging Unit | Keg Filling Machine,Keg Washing Machine |

Bottles Filling Line | |

Beer Canning Line |

Company Profile

Product packaging