200ml 300ml 500ml Drinking Pure Water Sachet Manufacturing Machine to Cut Water in Bag

1 set(s)Minimum order

machinery capacity:

2000BPH

application:

Machinery & Hardware, Beverage, Water

packaging type:

Bags, Pouch

packaging material:

Plastic, Pouch

automatic grade:

Automatic

driven type:

Electric

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| machinery capacity | 2000BPH |

|---|---|

| application | Machinery & Hardware, Beverage, Water |

| packaging type | Bags, Pouch |

| packaging material | Plastic, Pouch |

| automatic grade | Automatic |

| driven type | Electric |

| Voltage | 220V |

| place of origin | Guangdong, China |

| brand name | Fostream |

| dimension(l*w*h) | 820*780*1900 mm |

| warranty | 1 Year |

| key selling points | Easy to Operate |

| filling material | Water |

| filling accuracy | 99.5% |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, PLC |

| Filling Liquid | Pure Water, Milk, Soybean milk, Juice |

| Function | Forming Filling Sealing |

| Packing Film Material | Single Layer PE Film |

| Film Thickness | 0.08 mm |

| Packing Capacity | 1500-2000 Bags Per Hour |

| Packing Speed | 30-35 bags/minute |

| Packing Volume | 200-600 ml |

| Film Developed Width | 240-320 mm |

| Filling accuracy | ≤± 5mm (Liquid Level) |

| Precision | ±1% |

| Type | Filling Machine |

| Condition | New |

| Showroom Location | Kenya |

| Warranty of core components | 1 Year |

| Applicable Industries | hotels, Manufacturing Plant, Food & Beverage Factory, Sachet Water Plant |

| Weight | 450 KG |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

Good Price Plastic Bag Drinking Pure Water Making Machine in Bag

Products Description

Automatic Plastic Pouch Sachet Water Filling Machine It is applicable for packing the liquid like pure water, mineral water, fruit juice, milk, soy milk and coconut milk etc

1) Basic features of the sachet water machine:

Auto Film Feeding+ Vertical Forming Sealing + Horizontal Sealing + Quantitive Filling + Uv System + Date Coding / Counting

2) Structure of the machinery:Basic Type: SJY-1000 Series Technical Specification

2) Structure of the machinery:Basic Type: SJY-1000 Series Technical Specification

01. Frame and Liquid Contacting parts are S.S304. Equipped with water pump for the water filling purpose and motor and speed

reducer control unit for the speed control of the film distribution system.

02. Film dispensing unit: is composed of film setting system, film guiding SS304 steel post, vertical thermal heating sealing

rubber and the copper system, horizontal thermal sealing and cutting system. The film will be

forming according to the film setting process, to make the bags ready for filling water.

03. Filling unit: is composed of water pump, inlet control valve, Quantities will be depending on the piston type filler.

04. Auto sealing system: is composed of the film inlet guiding post, wheel, and the thermal heating modular, thermal heating tube,

temperature controller, and pressure adjusting spring valve.

05.Film output system: is composed of SS304 sliding rail plate.

06.Electrical control system: is composed of control panel, wiring, and the AC contactor system.

07.UV sterilizer and date coder is equipped on the machine

08.Data counting unit is equipped on the front panel.

09.Photo sensor for the speed control and the logo position correcting system will be equipped on the FS-2000BPH Series

01. Frame and Liquid Contacting parts are S.S304. Equipped with water pump for the water filling purpose and motor and speed

reducer control unit for the speed control of the film distribution system.

02. Film dispensing unit: is composed of film setting system, film guiding SS304 steel post, vertical thermal heating sealing

rubber and the copper system, horizontal thermal sealing and cutting system. The film will be

forming according to the film setting process, to make the bags ready for filling water.

03. Filling unit: is composed of water pump, inlet control valve, Quantities will be depending on the piston type filler.

04. Auto sealing system: is composed of the film inlet guiding post, wheel, and the thermal heating modular, thermal heating tube,

temperature controller, and pressure adjusting spring valve.

05.Film output system: is composed of SS304 sliding rail plate.

06.Electrical control system: is composed of control panel, wiring, and the AC contactor system.

07.UV sterilizer and date coder is equipped on the machine

08.Data counting unit is equipped on the front panel.

09.Photo sensor for the speed control and the logo position correcting system will be equipped on the FS-2000BPH Series

Main Technical Parameters

MODEL | FS-2000BPH |

Capacity | 2000-2200Bags/Hour |

Volume | 200ml-500ml |

Power | 220V/380V 1.6KW |

Film Width | 320mm/240mm |

Weight | 400kgs |

Size | 970*870**1970mm |

Details Images

(FSQ-RO-1000)1000 Liters Per Hour RO Water Purification Machine

(FSQ-2000BPH) Sachet Water Filling Machine

Real Scene Shoots

No.1 Water Production Line on Alibaba.

19 Years Alibaba Verified Gold Supplier.

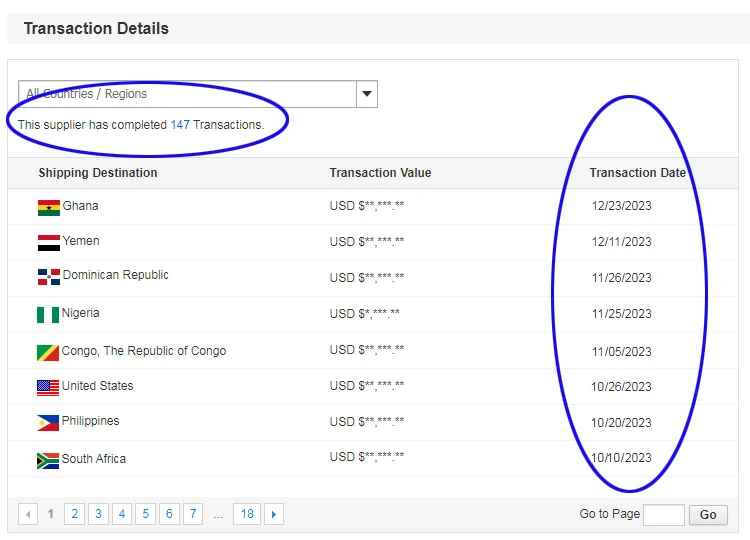

27 Years Production Experience.147 Online Transactions Completed.

12,500 Square Meters Standard Factory.

180,000 USD Alibaba Trade Assurance.

1,750,000 USD Online Transaction Volume.

7,800,000 Yuan RMB Registered Capital.

ISO 9001:2008 Quality Management System.

CE Certified & TUV SUD Capability Assessment.

Guangdong First Intelligent Drinking Water Equipment Co., Ltd.

Factory Address : No.141 Plant, Qingnian Road, Chaolian Town, Pengjiang District, Jiangmen City, Guangdong Province, China (It is one and a half hours' drive from Guangzhou)

Certification Verified

27 Years professional design and manufacturing experience.

Transaction History Verified

This supplier has completed 147 Transactions.

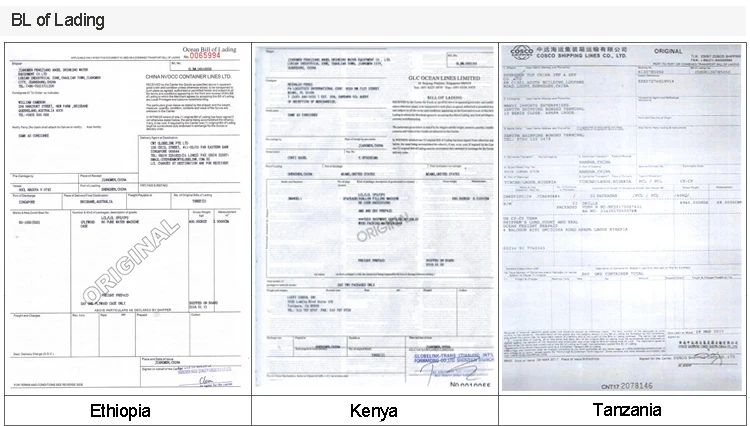

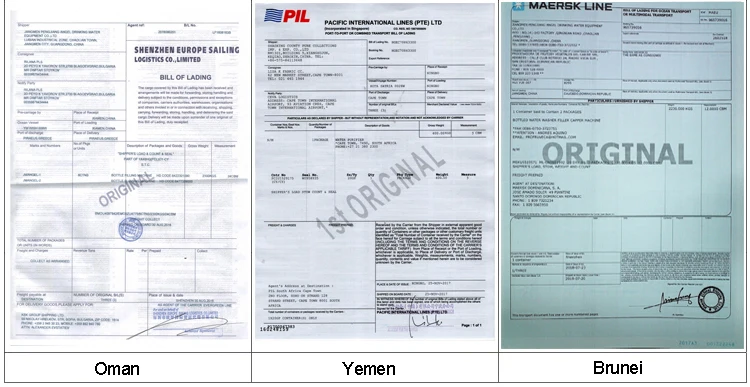

Our products are sold well not only in domestic, but also in Chile, Venezuela, Ghana, Kenya, Egypt, Peru, Maldives, United States, Brunei, Darussalam, Saudi Arabia, Panama, Cambodia, Bhutan, Bolivia, Bulgaria, Nicaragua, Dominican Republic, Somalia, Australia, Switzerland, Mozambique and other countries.

FAQ

Guangdong First Intelligent Drinking Water Equipment Co., Ltd.

Add: No.141 plant, Qingnian Road, Chaolian Town, Pengjiang District, Jiangmen, Guangdong, ChinaQ1. Are you a factory or trading company?

A1. We are a professional water treatment and filling machine manufacturing factory that set up for 27 years.We always pay attention to the development of the industry !.We can give a discount according to the quantity of machine you purchase. (19 years Alibaba Gold supplier)

B1. At the same time,we take effective measures to control the production process for ensuring the quality of products. Our products are certified.And we can supply SGS, BV, TUV, ISO9001, ISO14001, OHSAS18001, CE certification.

C1,Website: www.fostream.com

Website on alibaba: https://jmangel.en.alibaba.com

Q2. Where is your factory located? How can I visit there?

A2:Our factory is located in No.141 plant, Qingnian Road, Chaolian Town, Pengjiang District, Jiangmen, Guangdong, China, All our clients, from home or abroad, are warmly welcome to visit us!

Q3. What products does your company offer by yourself?

A3:We are specialized in water treatment machines, sachet water filling machines,small bottle water filling machines, 5 gallon water filling machines.

Q4: When can I get my machine after I paid?

A5: Normally production time is around 15 - 25 working days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

Q5: How long of your warranty?

A6: Regarding warranty, normally we offer 1.5 year warranty, and we also offer lifetime maintenance.

Welcome to China! Welcome to our factory!

(From Guangzhou Baiyun International Airport to our factory need only 85 minutes.)