200tpd Complete Set Mineral Separation Plant Nickel Ore Beneficiation Machine Nickel Processing Plant

US $79,870.00-83,100.00 / set

1 set(s)Minimum order

Type:

Mineral processing equipment

Production Capacity:

10-2000 t/h

Place of Origin:

Henan, China

Brand Name:

ZOOMJO

Voltage:

220/380/440V

Dimension(L*W*H):

Customizable

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Mineral processing equipment |

|---|---|

| Production Capacity | 10-2000 t/h |

| Place of Origin | Henan, China |

| Brand Name | ZOOMJO |

| Voltage | 220/380/440V |

| Dimension(L*W*H) | Customizable |

| Weight | 10000 KG |

| Warranty | 2 years |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | motor, Bearing, Gear, Engine, Gearbox, Other |

| Key Selling Points | Easy to Operate |

| Product Name | Nickel Flotation Process Plant |

| Application | Pyrite, copper-nickel ore or nickel oxide ore |

| Color | Customers' Requirements |

| After Sale Service | Engineer Overseas Service |

| Price | Competetive (Can Negotiate) |

| Factory | 50,000 Square Meters Closed Workshops |

| Installation and Trial | We Can Send Engineer for Guidance |

| Certification | ISO9001 CE, ISO9001:14000 |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location | Philippines, Indonesia, Pakistan, Mexico, Russia, Kenya, South Africa, Uzbekistan, Tajikistan |

| Condition | New |

| Warranty of core components | 2 years |

| Marketing Type | New Product 2022 |

Product Detail

Product Description

500tpd Complete Nickel Rock Beneficiation Process Plants Design Nickel Ore Processing Plant with Best Service

Nickel ore has good chemical stability, ductility, melt resistance and high temperature resistance and other excellent characteristics, is a very important non-ferrous metal raw materials, widely used in the manufacture of stainless steel, high nickel alloy steel and alloy structural steel. When the nickel content of nickel ore more than 3%, can be directly smelted, and used to produce a variety of nickel-containing materials; when the nickel content of nickel ore is less than 3%, it must be enriched through the beneficiation process to purify nickel, and then can enter the smelting process. Because the composition of different nickel ores is different, so in the beneficiation process, according to the composition of different nickel ores, choose the appropriate technology and equipment.

Extraction Process of Nickel Ore

Nickel ore mainly includes copper nickel sulfide ore and nickel oxide ore (laterite nickel ore). The extraction and processing methods of these two are very different: different extraction methods are selected according to the grade of nickel sulfide ores, and then nickel is prepared in different ways; the smelting methods of nickel oxide ores are usually divided into two types: dry and wet.

In copper-nickel sulfide ores, copper exists mainly as chalcopyrite, while nickel exists mainly as free nickel sulfides (e.g., pyrite, hematite, and pyroxene). A considerable portion of the nickel is present in a similar manner in pyromorphite, along with small amounts of nickel silicates. The most important extraction method is flotation, with magnetic separation and re-election usually being secondary extraction methods. In the flotation of copper and nickel sulphide ores, trapping and frothing agents are usually used in the flotation process of copper sulphide minerals. During smelting, nickel in the copper concentrate is lost, while copper in the nickel concentrate can be more completely recovered.

Oxidized nickel ores primarily use processes such as crushing and screening to advance the removal of large chunks of bedrock with a weak degree of weathering and low nickel content. This is because the nickel in oxidized nickel ores is usually dispersed in a similar manner in the surrounding rock minerals and is very fine grained. Therefore, it cannot be enriched by mechanical extraction methods and can only be directly smelted.

Common flotation methods for copper-nickel ores | Application Scenarios |

Copper-Nickel Mixed Flotation | Copper content is lower than nickel content. |

Copper-nickel separation | Coarser-grained, less tightly embedded copper-nickel ores. |

Preferential flotation of copper ore | The copper content of the ore is much higher than the nickel content. |

Copper-Nickel Mixed Flotation + Tailings Recovery | There are a variety of nickel minerals contained in copper-nickel ores. |

ZOOMJO MINING MACHINERY offers a wide range of solutions for beneficiation of gold, silver, copper, iron, zinc, chromium, molybdenum, feldspar, manganese ore and many more other ore materials.We can provide advanced beneficiation technology, beneficiation plant design, equipment fabrication and installation guidance on a turnkey basis!

Working Flow

Nickel Ore Beneficiation Plant

When treating copper nickel sulfide ores, it is common to use traps and frothing agents to get better results because it is easier to recover copper from nickel concentrates. The treatment of nickel ores usually involves three processes: crushing, grinding and extraction. Magnetic separation and re-election are usually secondary extraction methods.

Crushing and screening: The mined copper-nickel sulfide ore is fed through a feeder into a jaw crusher for initial crushing. After the initial crushing, the coarse copper-nickel sulfide ore particles are then sent to the cone crusher through the conveyor belt for secondary crushing. After secondary crushing, the copper-nickel sulfide ore is screened by the screening equipment, and the qualified ore particles can be directly sent to the next grinding process. Unqualified ore should be returned to the cone crusher for re-crushing.

Grinding and screening: Qualified copper-nickel sulfide ore particles are sent to ball mill for grinding, and the ore particles are ground into ore powder. Then it will be sent to the spiral classifier for sorting, if the particle size meets the requirements, the next step of flotation and purification can be carried out. Particles that do not meet the requirements need to be returned to the ball mill for secondary grinding.

Flotation Separation: Classified qualified copper-nickel sulfide ore is sent to the mixing tank for full mixing, and then sent to the flotation machine with reasonable flotation chemicals. The specific flotation method needs to find professional extraction manufacturers to carry out extraction test analysis of mineral properties. After professional analysis, the flotation purification process flow will be customized to meet the requirements according to the actual situation.

Dewatering and drying: After flotation, the water content of the material is relatively high, and the flotation concentrate material is sent to the thickener for initial concentration and precipitation. In order to accelerate the drying rate of the product, it is usually dewatered and separated using a thickener and then dried using a drier to obtain the finished product.

Main Equipment

Nickel ore processing equipment is divided into two series of smelting processing equipment and mineral processing equipment, mainly including, crusher, vibrating screen, washing machine, dryer, rotary kiln, electric furnace, dust removal equipment, ball mill, flotation machine, magnetic separator, jigger etc.

The specific configuration of mineral processing equipment should be designed according to the nature of the ore and the corresponding optimal process. Different physical and chemical properties of different ores are different, need to use different beneficiation technology and equipment in order to achieve the best beneficiation effect.

Customer Cases

ZOOMJO's mining process equipment, including high efficiency concentrator, crusher, ball mill, agitator tank, flotation machine, screening equipment, drying equipment, etc., have been successfully sold to more than 160 countries around the world, covering South Africa, Tanzania, Nigeria, Ethiopia, Kenya, Egypt, Zambia, Uganda, Ghana, India, Indonesia, Singapore, Australia and other countries.

Product Packaging

Packaging Details: We will make different packaging according to different machine sizes. Standard international export packing, container, wooden box.

Delivery Time: We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Our Advantages

EPCM all-inclusive service

ZOOMJO not only focuses on the manufacturing of mining equipment, but also provides a full range of services from engineering consulting, beneficiation test and research, to equipment manufacturing, installation and commissioning, personnel training, long-term tracking service and plant management and operation, so as to enable customers to realize one-stop solutions, shorten the construction period, and realize the benefits earlier.

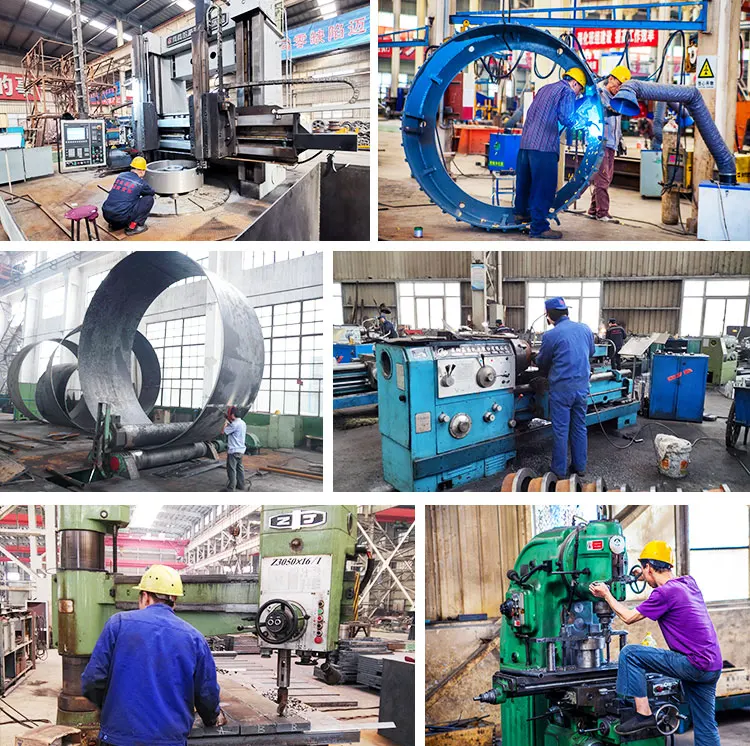

High quality mining equipment

ZOOMJO in the production of equipment, from procurement to quality control process strictly control, to ensure that the raw materials are flawless. At the same time, each product is fully inspected and pre-acceptance, and debugging, to eliminate quality problems.

Shipping and Transportation

The equipment will be shipped in time after completion of manufacture. If the contract requires guided installation or contracted installation, after the site has the installation conditions, the company will quickly send staff on-site operation, and establish customer files, provide permanent tracking service to ensure long-term normal operation of the project to avoid customer losses. At the same time, we provide one year warranty for the whole machine, if there is any problem, you can contact us to deal with it.

About after-sales service

ZOOMJO after-sales service team consists of 50 experienced technicians, including old experts and senior technicians with more than 20 years of mining experience. We promise to arrive at the scene within 24 hours at home and 48 hours abroad (excluding passport time) to solve the problem quickly, which will greatly shorten the production downtime and reduce the loss of customers.

Company Profile

ZOOMJO is a large-scale enterprise that mainly produces heavy mining machinery and integrates scientific research, production and sales. It mainly produces various large and medium-sized crushing equipment, sand making equipment, drying and calcining equipment, mineral processing equipment and other series of products.

ZOOMJO has developed steadily from its establishment to the present with its technical strength, and has grown stronger day by day, and has gathered a large number of high-level management and scientific research personnel. Our company covers an area of 50,000 square meters, and another 10,000 square meters of modern office space, R&D center and sales center. The company has more than 500 employees, including more than 20 intermediate technicians. With strong technical strength, scientific management system and high product quality, ZOOMJO will rapidly grow into an important production and export base of mining machinery.

FAQ

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.