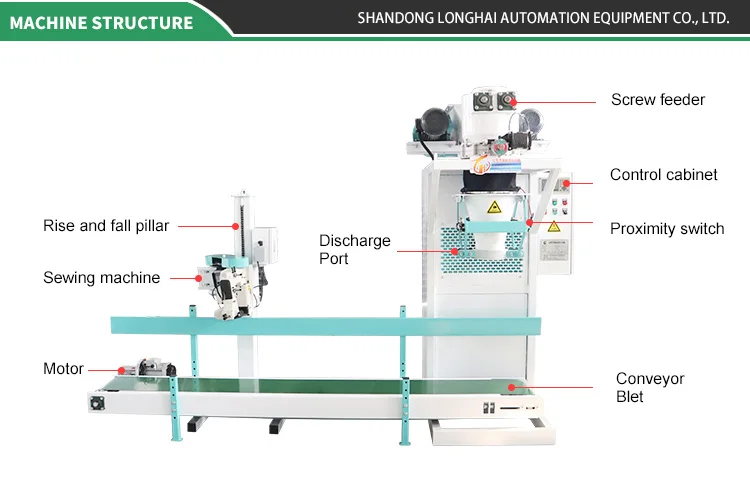

20kg 10kg 5kg SS Automatic Flour Packaging Machine Coffee Corn Filling Maize 25kg Rice Milk Powder Wheat Flour Packing Machine

US $3,180.00-4,500.00 / set

1 set(s)Minimum order

production capacity:

20bag/min, 40bag/min, 25bag/min, 10bag/min, 50bag/min

Weight (KG):

550

function:

FILLING, Wrapping, Sealing

application:

Food, Chemical, Machinery & Hardware

packaging type:

Bags

packaging material:

Plastic, paper, metal, Glass, Wood

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| production capacity | 20bag/min, 40bag/min, 25bag/min, 10bag/min, 50bag/min |

|---|---|

| Weight (KG) | 550 |

| function | FILLING, Wrapping, Sealing |

| application | Food, Chemical, Machinery & Hardware |

| packaging type | Bags |

| packaging material | Plastic, paper, metal, Glass, Wood |

| automatic grade | Semi-automatic |

| driven type | Pneumatic |

| Voltage | 220V, 380V/220V or Customized |

| place of origin | Shandong, China |

| brand name | Longhai |

| dimension(l*w*h) | 300*100*220cm |

| warranty | 1 Year |

| key selling points | Easy to Operate |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | PLC |

| Driven Type | Pneumatic |

| Product name | Bag Packaging Machine |

| Packing speed | 160--260 bags/h |

| Bag type | Seal/sew Bag |

| After Warranty Service | Video Technical Support |

| After-sales Service Provided | Field Installation, Commissioning and Training |

| Type | Multi-Function Packaging Machine |

| Applicable Industries | Food & Beverage Factory, Food Shop, Energy & Mining, Food & Beverage Shops |

| Showroom Location | Viet Nam, Brazil, Indonesia, Pakistan, India, Russia, Romania, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia |

| Condition | New |

| Warranty of core components | 1 Year |

Product Detail

Bagging scales are devices that allow products to be bagged quickly and accurately, speed up the production process

of businesses and save on labor costs. They are used in many sectors, especially in agriculture, chemistry, food processing and construction materials sectors. Factors such as capacity, precision, durability and ease of use should be considered when choosing a bag filling machine. By choosing a bagging scale that suits their needs, businesses can perform accurate measurement and bagging operations.

Model No. | Metering range | Speed | High | Describe | |||

DCS-L-W-50 | 15-50kg | 150-180 bags/h | 2200 mm | Scale body, 3-meter conveyor, foot operated sewing machine, column | |||

DCS-L-W-50 | 15-50kg | 180-200 bags/h | 2200 mm | ||||

DCS-L-S-50 | 15-50kg | 300 bags/h | 2800 mm | ||||

DCS-L-D-50 | 15-50kg | 400-500 bags/h | 2950 mm | Scale body, 4-meter conveyor, infrared sewing machine, column | |||

DCS-2L-W-50 | 15-50kg | 400 bags/h | 2250 mm | ||||

Paking | Powdered and flowable material premixes, fertilizers, flour, starch, feed, silicon powder, alumina | ||||||

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

The sewing machine adopts a foot switch to control the start and stop of the machine, and a hidden cutting blade is used to cut the braids of the thread; The key parts are made of high-quality alloy steel and alloy copper wear-resistant materials, with a long service life and convenient maintenance

The speed can be adjusted arbitrarily, the elasticity of the belt body is not easy to deform, and the wear resistance and high temperature are automatically transmitted.

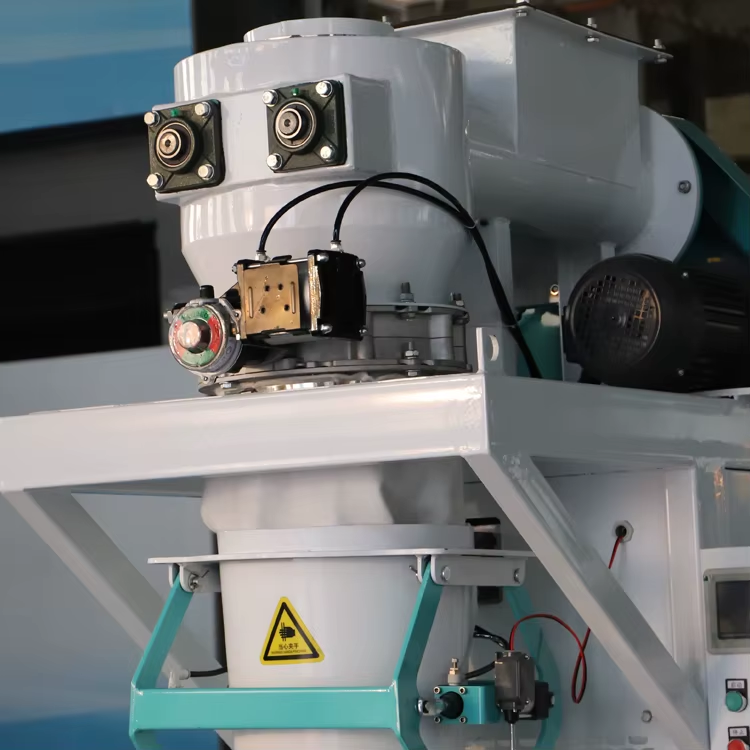

Bagging Scale System

High calculating precision, rapid packaging speed, stable function, easy operation.

Adopt advanced techniques on control instrument, sensor, and pneumatic components.

Advanced functions: automatic correction, error alarm, automatic error detection.

Adopt advanced techniques on control instrument, sensor, and pneumatic components.

Advanced functions: automatic correction, error alarm, automatic error detection.

MACHINE COMPONENTS

SDA- thin cylinder

TCL- triaxial cylinder

weighing sensor

Solenoid valve

Planetary reducer

Control instrument

OPTIONAL

Pneumatic sealing machine

Automatic conveying

sewing machine

Folding Machine

Sewing Machine

Sewing Machine

Conveying sewing machine

FAQ

Q1:How to choose suitable packing machine?

A1:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q2:How to ensure the quality of the machine?

A2: We usually delivery the machine after successful inspection in our factory. We have our own quality control department,beforethe delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q3:Are you trading company or manufacturer?

A3:We are factory with best prices, strict QC inspection, guaranteed quality, custom service based on site environment and professional advice for best solution.

Q4: How about your delivery time?

A4:Generally, it will take 5 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5: How to install the equipment?

A5: We will provide manuals and detailed videos to help customer install machine. If necessary, we will arrange engineer to the customer's factory to assist.

Q6: What's your payment way?

A7: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

Q7: Why we should choose your company?

A7: We are professional in packing machines over 10 years, and we provide better after-sales service. We guarantee no risk for our deal.