300L 3HL 2BBL 400L 500L Stainless Steel Double Wall Glycol Jacketed Top Manway Conical Brewery Fermenters for Sale

Other recommendations for your business

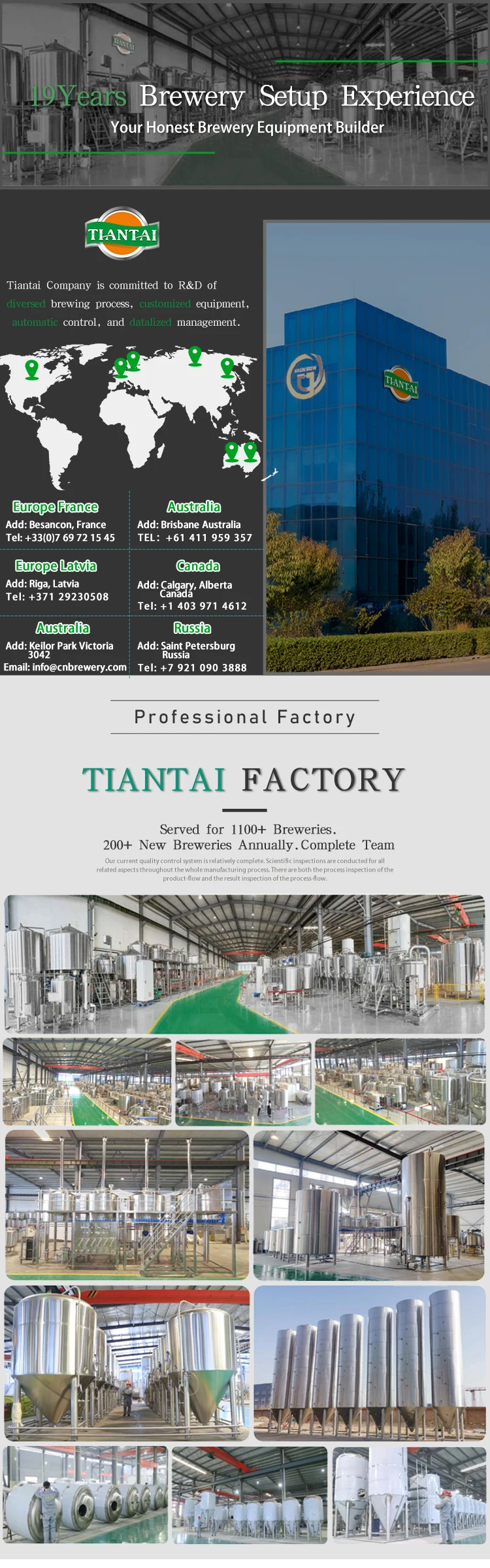

Contact us

Quik Detail

| processing | Other |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| place of origin | Shandong, China |

| brand name | Tiantai or OEM |

| model number | 300L brewery |

| weight | 1200 KG |

| dimension(l*w*h) | 910mmx910mmx2200mm |

| processing types | Alcohol |

| warranty | 5 years |

| Product name | 300L brewery equipment |

| Application | Wine Whiskey Vodca Gin Tequila Brandy |

| Capacity | 300L |

| Heating | Electrical |

| Cleaning | CIP System |

| Color | Silver |

| Control System | Semi-automatic |

| Package | Plywoodcases |

| Surface Treatment | Polished |

| Applicable Industries | hotels, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use, Food Shop, Food & Beverage Shops |

| Showroom Location | Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Indonesia, Mexico, Spain, South Korea, Chile, Japan, Malaysia, Australia |

| Marketing Type | New Product 2020 |

| Warranty of core components | 5 years |

| Condition | New |

Product Detail

300L 3HL Stainless steel double wall glycol jacketed top manway conical brewery fermenters for sale

1.Production Description

Cylindroconical fermenters are the most commonly used fermentation systems used today to produce both lagers and ales.

As the name implies, the vessels are vertical cylinders with a conical base (usually 60°cone) and normally, a dished top.

This design allows for easy yeast collection and CIP cleaning.

300L 3HL Stainless steel double wall glycol jacket top manway beer brewery fermentation tank are very suitable for micro breweries and brewpubs, bars etc. It’s self-cooled with glycol water inlet and outlet, so the temperature of beer during fermentation can be controlled easily.

In addition, each beer fermentation tank is equipped with 360°rotated CIP spraying ball.

The tank inner could be cleaned completely. This can ensure the food-grade sanitary of beer production.

The 300L fermenter is usually installed with 300L beer brewing system or 150L small beer brewpub equipment.

Based on different beer types requirements on output and fermentation cycle, usually 4-20 sets beer fermentation tanks are needed by most of the customers.

2.Product Advantage

--Company certificated by ISO TUV SGS production process inspection, the tanks’ design and quality can be according to GB/CE/PED/ASME standard.

--Local service in EUROPE, AUSTRALIA etc.

--5 Years warranty for tanks.

--0 trade risk verified by more than 1100 breweries.

--19 Years experience design customization.

--Electrical parts CSA/UL certificated available.

3.Product Features

--Made of Stainless steel 304, TIG welded by automatic welding machine, the tanks’ quality according to GB/CE/PED/ASME standard.

--Interior polished to 0.2-0.4 μm to ensure no dead corner for bacteria hide in. Totally avoid the sanitary issues.

--Triangle-Arranged holes on glycol jacket for higher cooling efficiency.

--Rotating Racking arm allows beer out separately with yeast.

--All gasket made of EPDM which have a more durable use time.

--Fermentation pressure adjustable, suitable for fermentation both under atmospheric pressure and specific pressure.

--Separated cooling zones on side wall and cone for more accurate temperature control.

--Completely SUS304 legs with strengthening braces to prevent tank deformation.

-- Heavy duty foot pads with adjustable ability, can be applied to uneven or slope ground.

4.Product Specification

|

Tank Capacity: |

300L (+25% Headspace minimum) |

|

Dimension: |

Φ960mmx 1900mm (Can be customized) |

|

Tank Material: |

SUS304 (SUS304L/SUS316/Copper available) |

|

Inner/Outer Shell Thickness: |

3mm/2mm |

|

Insulation: |

PU foam; TH=80mm |

|

Working Pressure: |

0.2 Mpa |

|

Testing Pressure: |

0.25 Mpa |

|

Glycol Jacket: |

Dimpled plate on cone and side |

|

Manway position: |

Top |

|

Arms installed on tank: |

CIP arm, discharge arm |

|

Accessories: |

CIP ball, sample valve, PVRV valve, pressure gauge, rotating racking arm, Thermowell. Level indicator, carbonation stone, bunging valve,dry hopping port , CO2 blow-off arm,for special request. |

Note: The dimensions and location of ports on the fermenters can be customized according to the space limitation/customer requirements.

5.Product Details

All accessories of the 3HL beer fermenters are food grade standard:

Send Inquiry>>

Click to Contact Us Now!