300L Barley Malt Beer Making Machine Fermenting Equipment

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| processing types | Beer |

| voltage | 208/380V or customization |

| power(w) | 25KW |

| dimension(l*w*h) | 25 Cubic Meter |

| weight | 2400 KG |

| warranty | 5 Years |

| Machinery Capacity | 300L |

| machinery test report | Provided |

| core components | Gearbox, motor, Pump, Pressure vessel, PLC, Bearing |

| key selling points | Long Service Life |

| video outgoing-inspection | Provided |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Name | 300L barley malt beer making machine fermenting equipment |

| Material | Stainless Steel 304/316 & Copper |

| Thickness | Inner 3mm External 2mm |

| Heating Method | Steam,Electric,Direct Fire |

| Cooling way | Dimple jacket |

| Cooling media | Glycol water |

| Control system | Semi-automatic |

| Function | Beer Brewing |

| Technical Support | 2D&3D Drawings Available |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Food & Beverage Shops |

| Showroom Location | Canada, United Kingdom, United States, France, Australia |

| Condition | New |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 year |

Product Detail

300L barley malt beer making machine fermenting equipment

1. 300L Brewery Basic Configurations

| Architecture | Main Components |

| 1.Trituration System | 01.Malt Mill |

| 2.Heating System | 01.Steam Boiler(Optional) 02.Burner(Optional) 03.Electric Heating(Optional) |

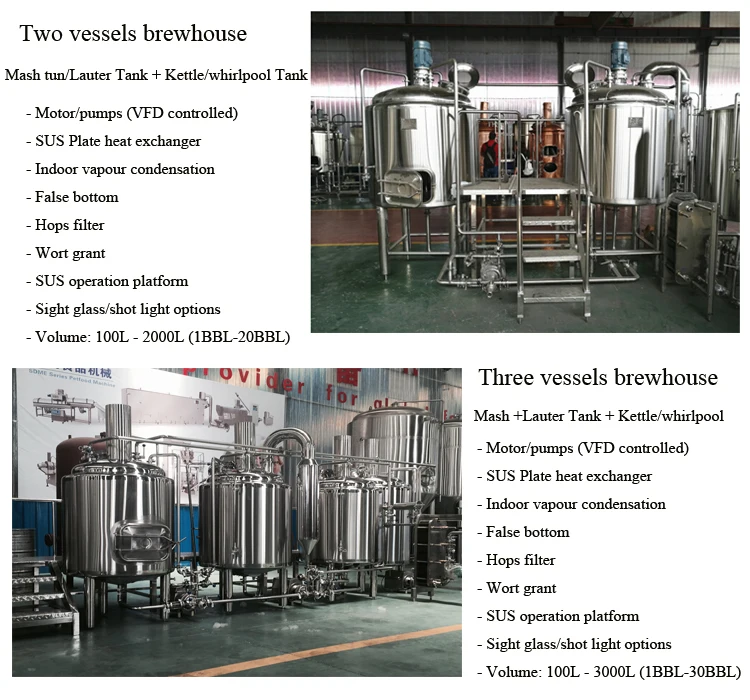

| 3.Saccharification System | 01.Mash Tun / Lauter Tank & Brew Kettle/Whirlpool Tank (2 Vessel) 02.Mash Tun & Lauter Tank & Brew Kettle/Whirlpool Tank(3 Vessel) 03.Mash Tun / Lauter Tank & Brew Kettle & Whirlpool Tank(3 Vessel) 04.Mash Tun & Lauter Tank & Brew Kettle & Whirlpool Tank(4 Vessel) |

| 4.Fermentation System | 01.Fermentation Tank 02.Bright Tank |

| 5. Cooling System | 01.Glycol Tank 02.Glycol Unit |

| 6. Cleaning System | 01.Disinfection Tank 02.Alkali Tank |

| 7. Control System | 01.PID 02.PLC(Siemens) |

| 8.Packing system | 01.Bottling 02.Canning 03.Kegging |

2. 300L Mashing System

300L brewhouse can be in various combination:

You May Also Like Other Brewhouse Types:

Send Inquiry>>

3. 300L Fermentation System

1). A serials of the fermetation tanks

|

Fermentation tank series |

Volume in US Gallon |

Diameter |

Height |

|

100l Fermentation tank |

26US Gallon |

640mm |

1500mm |

|

200l Fermentation Tank |

53US Gallon |

760mm |

1800mm |

|

300l Fermentation Tank |

79US Gallon |

860mm |

2000mm |

|

500l Fermentation Tank |

132US Gallon |

960mm |

2350mm |

|

1000l Fermentation Tank |

264US Gallon |

1260mm |

2650mm |

|

2000l Fermentation Tank |

264US Gallon |

1560mm |

3150mm |

|

3000l Fermentation Tank |

528US Gallon |

1800mm |

3550mm |

|

5000l Fermentation Tank |

1321US Gallon |

200mm |

4450mm |

2). Specifications of 300L fermentation tanks:

| No. |

Item |

Introduction |

|

01 |

Volume |

300L |

|

02 |

Dimention | 860*2000mm |

|

03 |

Material |

Stainless steel 304 |

|

04 |

Insulation |

Polyurethane, TH: 80mm |

|

05 |

Fermentation tank |

Glycol jacket: Dimpled jacket on the cone and side Or single wall with jacketed, or single layer fermentor. |

|

06 |

Head |

Double or single dish head on the top |

|

07 |

Accessories |

Sample valve, pressure gauge, solenoid valve, pressure relief valve, racking arm, CIP arm and Blow off arm, dry hops port, and so on. |

3). Details of 300L Fermentation Tanks:

Send Inquiry>>

4. Grouped Equipment

We offer all necessary peripheral equipment to ensure that your brewery / Brewpub has everything it needs for a high quality brew and the means to give your clients the best drinking experience.

1). Malt Miller

01.Double Roller

02.Adjustable roller width, little dust, low noise

2). Cooling system

01.Glycol Chiller

02.Chiller

3). CIP Tanks

01.Disinfection Tank

02.Alkali Tank

4). Control Cabinet

01.Schneider low voltage electrical components; Danfoss VFD;

02.Wiring diagram will be provided with the panel;

03. wiring diagram and English nameplate.

04.All motors must have fuse and overload protection.

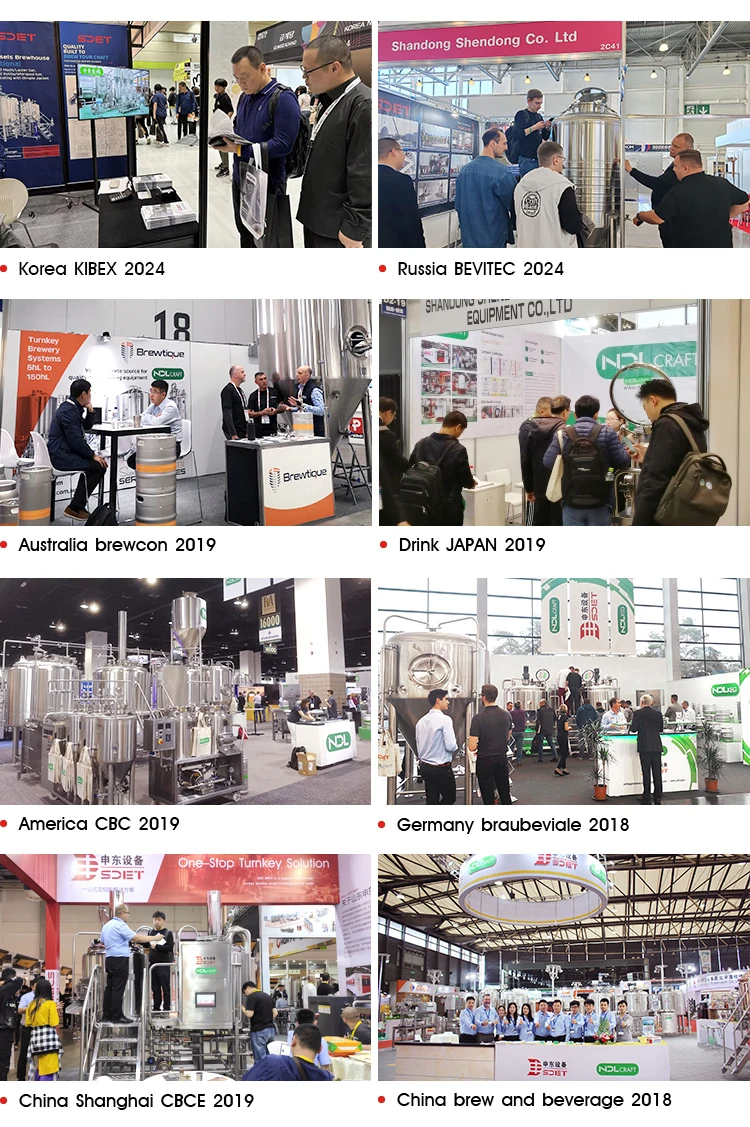

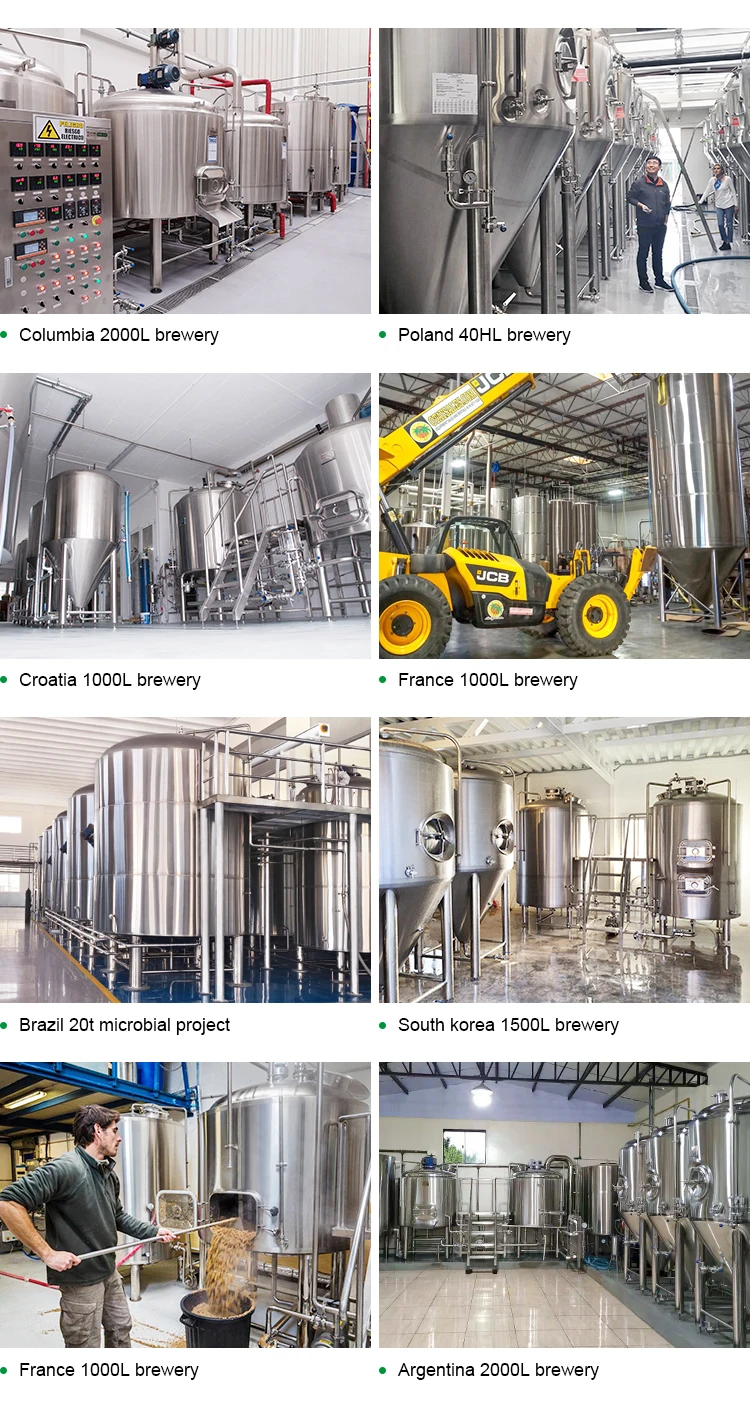

SDET, founded in 2011, is a brewing equipment manufacturer and brewing technology engineering company that provides many kinds of customized tanks and turnkey projects throughout the world. The company attaches great importance to the research and development of core technology. On the basis of maintaining the manufacturing cost of China, the company can design according to CE PED standards and ASME design codes, and institutes production and quality control methods according to both European and American quality standards.

We have established an ERP management system and have passed quality audits for internationally recognized certifications.

ISO 9001: Certification for the Quality Management System

ISO 14001: Certification for the Environmental Management System

ISO 18001: Certification for the Occupational Healthland Safety Management System

CE: Certification of Compliance

PED(TUV): Certification of Compliance, Certification of Conformity

SGS: Gold Plus Supplier Assessment Certificate

Send Inquiry>>

Click to Contact Us Now!!!