400x600 Mobile Mini Small Stone Brick Crusher Hammer Crusher Glass Recycling Hammer Mill

US $1,200.00-1,900.00 / set

1 set(s)Minimum order

Type:

Hammer Crusher

Application:

Stone crushing, bricks , concrete , limestone ect

Motor Type:

AC Motor

Capacity(t/h):

5-10

Place of Origin:

Henan, China

Brand Name:

Shibo

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Hammer Crusher |

|---|---|

| Application | Stone crushing, bricks , concrete , limestone ect |

| Motor Type | AC Motor |

| Capacity(t/h) | 5-10 |

| Place of Origin | Henan, China |

| Brand Name | Shibo |

| Dimension(L*W*H) | 900*670*860mm |

| Weight | 0.8 KG, 0.8t |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Gear, Other, motor, Bearing |

| Key Selling Points | Competitive Price |

| Name | Small stone crusher hammer crusher glass recycling hammer mill |

| Model | PC400*300 |

| Max feeding size | 200mm |

| Output size | 0-25mm adjustable |

| Capacity | 5-10tph |

| Power | 11kw |

| Dimensions | 900*670*860mm |

| Certification | CE ISO |

Product Detail

Specification

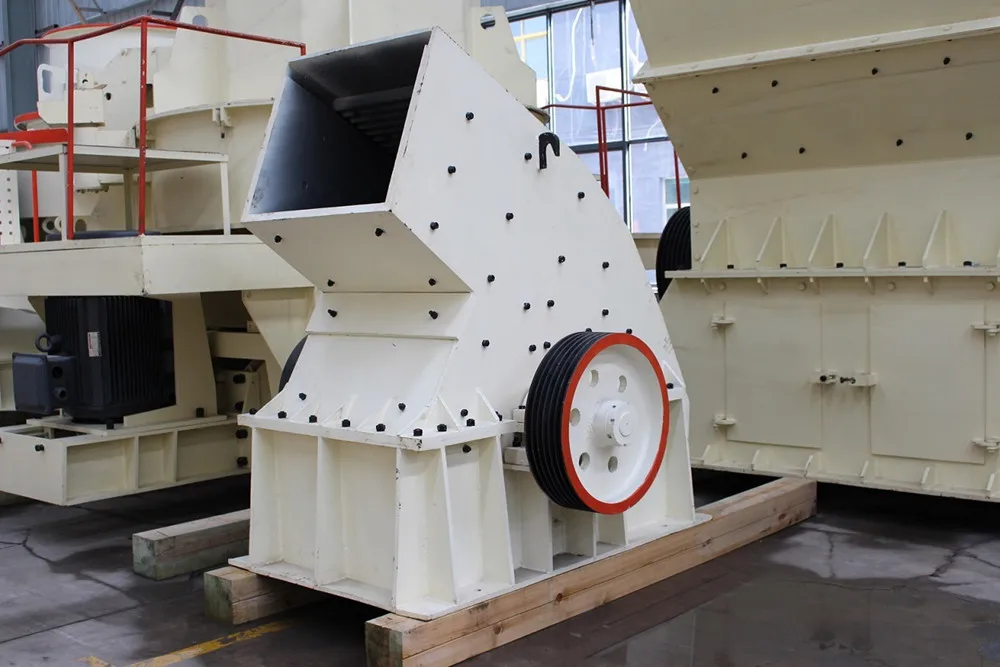

Hot Sale Hammer Crusher In Zimbabwe Stone Hammer Mill Price

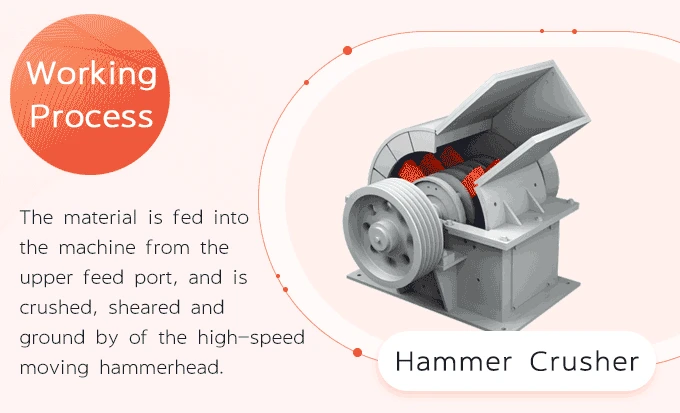

Hammer crusher is applicable for various medium hard and fragile materials, such as limestone, glass, coal, salt, gypsum, alum, brick, gold ore and tile etc. It has high production capacity, low energy consumption, simple structure, reliable quality, easy maintenance, etc. The hot sale models are PC 400*300, PC600*400, PC800*600, etc.

Model | Feeding Size(mm) | Discharging Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Overall Dimension(mm) |

PC400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900 × 670 × 860 |

PC600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200 × 1050 × 1200 |

PC800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310 × 1180 × 1310 |

PC1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600 × 1390 × 1575 |

PC1000×1000 | ≤500 | ≤35 | 30-80 | 90 | 8 | 1800 × 1590 × 1775 |

Coal gangue hammer crusher

These hammer crusher are the part of ceramsite sand production line , it used to crush the raw material coal gangue into 0-5mm sand

If the working site is short of electricity , it can also drive by diesel engine, This

kind of crusher is in compact structure, easy usage and simple operation. We also can do portable (mobile) ones as clients' request.

Advantages

1.convenient maintenance

2.wear resistant and impact resistant

3.compact structure,lees easy-wearing parts

4.sealed structure,less pollution and ash leakage of machine

5.The granularity can be adjusted according to the requirement

1.convenient maintenance

2.wear resistant and impact resistant

3.compact structure,lees easy-wearing parts

4.sealed structure,less pollution and ash leakage of machine

5.The granularity can be adjusted according to the requirement

Feature

the main working part of types of hammer mill is the rotor with hammers.The rotor consists of main shaft, disk,hinge pin and hammers.A sieve plate is below the rotor.The motor drives the rotor to rotate at a high speed.When the materials get into the crushing cavity,they are crushed by the rotating hammers,the crushed products which meet the required size can be discharged from the sieve plate and become the final products,the products with larger size are brought back to the crushed area for being re-crushed until they reach the required size

The grate gap of the equipment can be adjusted according to user requirements to get the different final sizes

In the hammer crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them; the crushed products meeting the required size can be discharged by the outlet and become the final products; the large size products are brought back to the crushing area by the hammers for being re-crushed until they reach the required size

PC400×300 and PC600×400 model crusher can packing in wooden box, bigger model crusher are nude packing ,accessories are packing in wooden box.

Stone Quarrying Hammer Brick Crusher Mill Machine is mainly used for crushing medium-hard

or brittle materials with hardness not more than 300Mpa and 15% moisture,such as coal, cement,gypsum,alumen,brick,tile,limestone,etc.It has the features of simple structure, big crushing ratio, high production

efficiency, uniform particle size, etc. This equipment can be adjusted to reach various discharged granularity as the customers' requests.

or brittle materials with hardness not more than 300Mpa and 15% moisture,such as coal, cement,gypsum,alumen,brick,tile,limestone,etc.It has the features of simple structure, big crushing ratio, high production

efficiency, uniform particle size, etc. This equipment can be adjusted to reach various discharged granularity as the customers' requests.

Packing & Delivery

Company Profile

Customer Photos

After more than 30 years development , now we have more than 100 world markets and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

FAQ

How to buy a machine i want to have ?

Please tell us more detials if you like, normally, we need: a, what kind of the stone it is, b, how about the input size and

output size you want, c, capcity. d, Any other requirement.\

How to pay?

Our company accpet L/C Payment and T/T payment. You can do that with a cooperated bank in your country.

How about the quality guarantee?

How to get the wear parts supports?

We supply the wear parts with very favourest price. Especially for the present cooperated customer, wear parts will be supplied without any benifit as a longterms cooperation support

Please tell us more detials if you like, normally, we need: a, what kind of the stone it is, b, how about the input size and

output size you want, c, capcity. d, Any other requirement.\

How to pay?

Our company accpet L/C Payment and T/T payment. You can do that with a cooperated bank in your country.

How about the quality guarantee?

Our material is checked carfully before buy them from brand supplier, so that guarantee the orginal quality. During the producing, every step will be recorded. When we get the finished products, we have more than 24 hours testing. Products quality is guaranteed for one year. We have a 24 hours resposnse system, any thing the customer required will be handled with within 24 hours. If the customer required, we can get the project place within 72 hours. For further, if needed, we acceped 5% as quality guarantee, but should be pay back within 15 days after sucessful test running.

How to get the wear parts supports?

We supply the wear parts with very favourest price. Especially for the present cooperated customer, wear parts will be supplied without any benifit as a longterms cooperation support