6 Cavity Drinking Mineral Water Blowing Plastic Bottle Making Machine Automatic With High Quality

US $26,800.00 / set

1 set(s)Minimum order

plastic processed:

PET

max.bottle height(mm):

365 mm

neck diameter(mm):

38 mm

max.bottle diameter(mm):

110 mm

bottle volume(ml):

2000 ml

place of origin:

Zhejiang, China

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PET |

|---|---|

| max.bottle height(mm) | 365 mm |

| neck diameter(mm) | 38 mm |

| max.bottle diameter(mm) | 110 mm |

| bottle volume(ml) | 2000 ml |

| place of origin | Zhejiang, China |

| brand name | ZEGO |

| voltage | 380V/3PH/50HZ/CUSTOMIZED |

| dimension(l*w*h) | 4040X1930X2040 mm |

| High Pressure Valve Brand | SMC |

| Rotary Cylinder Brand | SMC |

| PLC Brand | MITSUBISHI |

| power (kw) | 60 |

| weight (kg) | 6000 KG |

| automation | Automatic |

| warranty | 1 Year |

| key selling points | High Productivity |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | PLC |

| Description | 6 Cavity High Speed Plastic Bottle Making Machine Automatic |

| Key words | Automatic Extrusion Plastic Bottle Making Machine Automatic |

| Container volume | Within 2L |

| Theoretical output | 5500~7500pcs |

| Cavity | 6 cavities |

| Valve/Cylinder | Airtac/SMC |

| Suitable Bottle | water bottle/juice bottle/ cooking oil bottle etc |

| Use | Making PET Bottle |

| Color | Customer Customized |

| Advantages | Easy Operation |

| Condition | New |

| Application | Bottle |

| Showroom Location | Germany |

| Applicable Industries | Food & Beverage Factory |

| Warranty of core components | 3 years |

| Year | 2024 |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

Stepping mechanism:

Type : Servo motor drive

Brand: Mitsubishi Japan

Servo motor's synchronical high speed and precise positioning. Slide stepping by orbit is swift and stable with less cycle time and higher efficiency.

Type : Servo motor drive

Brand: Mitsubishi Japan

Servo motor's synchronical high speed and precise positioning. Slide stepping by orbit is swift and stable with less cycle time and higher efficiency.

Heating System

- constant temperature 120°C

- Rotary heating Ø

-Energy saving and low scrap rate

Transmission system

-Using the patented dual

-drive dual-point linear guideway structure

-High stability and long life cycle

- constant temperature 120°C

- Rotary heating Ø

-Energy saving and low scrap rate

Transmission system

-Using the patented dual

-drive dual-point linear guideway structure

-High stability and long life cycle

Auto-loader

-Auto-loader improves working efficiency, accurate transportation, reliable and durable, raw materials are completely free of moisture, pollution, foreign matter, and loss during feeding process. -Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

Drive Technology

-High precision Servo Motor

- Trouble-free and energy-efficient production

Blow Molding Technology

-Servo motor drives the stretching system - Highly flexible formwork

- Low consumption and high productivity

Air Recovery Technology

- 25% of high pressure gas can be recovered for machine operation

-High precision Servo Motor

- Trouble-free and energy-efficient production

Blow Molding Technology

-Servo motor drives the stretching system - Highly flexible formwork

- Low consumption and high productivity

Air Recovery Technology

- 25% of high pressure gas can be recovered for machine operation

Preform Feeding System

-360° Surround Design

-Preforms will not be left in the hopper

Preform recycling device -Reduce the jam of preforms

- effectively reduce by 10%

-360° Surround Design

-Preforms will not be left in the hopper

Preform recycling device -Reduce the jam of preforms

- effectively reduce by 10%

Electric control system

-PLC control system,simple operation

-fully automatic operation

-Solder treatment at the line interface, not easy to damage

-PLC control system,simple operation

-fully automatic operation

-Solder treatment at the line interface, not easy to damage

Technical parameter PET bottle blow machine | ||||||||||

Model | ZG-2000 | ZG-4000 | ZG-6000 | ZG-5000B | ZG-1000C | |||||

Cavities | 2cavities |

2cavities

|

2cavities

|

2cavities

|

2cavities

| |||||

Capacity | 2000bottles/hour | 4000bottles/hour | 2000 bottles/hour | 2000 bottles/hour | 2000 bottles/hour | |||||

Application | PET plastic bottle blowing machine | |||||||||

Bottle volume | 0.1-2L | 0.1-2L | 0.1-2L | 0.1-5L | 0.1-5L | |||||

Body diameter | <120mm | <120mm | <120mm | <200mm | <200mm | |||||

Max bottle height | <330mm | <330mm | <330mm | <400mm | <400mm | |||||

Main power | 25KW | 45KW | 75KW | 45KW | 45KW | |||||

Hp air compressor | 1.6 m3/min | 2.4 m3/min | 4.8m3/min | 2.4m3/min | 2.4 m3/min | |||||

LP air compressor | 1.0 m3/min | 1.6 m3/min | 2.0 m3/min | 1.6 m3/min | 1.6 m3/min | |||||

Machine sizes | 1.96*1.6*2m | 3.2*1.9*2m | 4.1*1.9*2m | 3.1*2.1*2m | 3.4*1.9*2m | |||||

Weight | 2000kg | 3600kg | 4500kg | 3800kg | 3000kg | |||||

Pneumatic parts | Touch Screen | Mitsubishi Japan |

PLC | Mitsubishi Japan | |

Blowing cylinder | SMC Japan | |

Mould Closing and operating cylinder | SMC Japan | |

Revolve cylinder | SMC Japan | |

Valve | Airtac Taiwan | |

Servo Motor | Delta Taiwan | |

Switch | Omron Japan |

1.YOU ARE WELCOME To OUR FACTORY AT ANY TIME. If we can full fill your request and you interested in our products, you may pay a visit to ZG Machine site.The meaning of visiting supplier, because seeing is believing,

2.Q: ARE YOU A FACTORY OR TRADING COMPANY?

3. Q: DO YOU PROVIDE BOTTLE BLOW MOULD AND AIR COMPRESSOR ?

A: Yes, we provide complete system and you will no need to find the suitable air compressor and chiller.... etc

4.Q: WHAT IS THE LANGUAGE OF THE PLC AND TOUCH PANEL?

A: Don't worry, we will translate the language in English,Spanish or any other language to make sure you will have an easy operation.

5.Q: HOW To GUARANTEE YOUR FUNDS To BE SAFE AND DELIVERY To BE ON TIME?

A:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.By letter of credit, you can lock the delivery time easily.. After the factory visit, You can ensure the facility of our bank

account.

6.Q:ZG MACHINE HOW To ENSURE THE QUALITY?

2.Q: ARE YOU A FACTORY OR TRADING COMPANY?

A: We are a factory directly supplier. ZG Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

3. Q: DO YOU PROVIDE BOTTLE BLOW MOULD AND AIR COMPRESSOR ?

A: Yes, we provide complete system and you will no need to find the suitable air compressor and chiller.... etc

4.Q: WHAT IS THE LANGUAGE OF THE PLC AND TOUCH PANEL?

A: Don't worry, we will translate the language in English,Spanish or any other language to make sure you will have an easy operation.

5.Q: HOW To GUARANTEE YOUR FUNDS To BE SAFE AND DELIVERY To BE ON TIME?

A:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.By letter of credit, you can lock the delivery time easily.. After the factory visit, You can ensure the facility of our bank

account.

6.Q:ZG MACHINE HOW To ENSURE THE QUALITY?

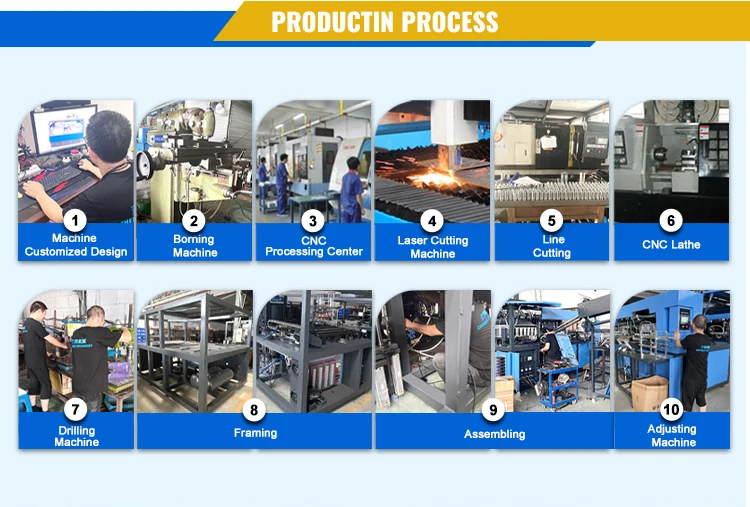

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years.After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

7.Q:THE AFTER-SALE SERVICE OF ZG MACHINE?

A:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment.

7.Q:THE AFTER-SALE SERVICE OF ZG MACHINE?

A:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.