8mm 10mm 12mm Steel Mini Wire Rod Hot Rolling Mill Automatic Rebars Iron Rod Making Machine Production Line Machinery

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Henan, China |

|---|---|

| brand name | SHENNAI |

| type | Hot Rolling Mill |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| voltage | Not standard |

| power(w) | 90 |

| dimension(l*w*h) | Not standard |

| warranty | 1 Year |

| key selling points | High Productivity |

| Application | steel rolling mill production line |

| Raw material | Steel Billets |

| Finished product: | rebars,angle and flat steel |

| Output | 1-3T/H |

| Advantages | Easy to maintain |

| Rolling type | Hot rolling |

| Final rebar size | < dia.20mm |

| Billet Size | 30x30mm |

| Main machine | rolling mill |

| Weight | 6.8T |

| Condition | New |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

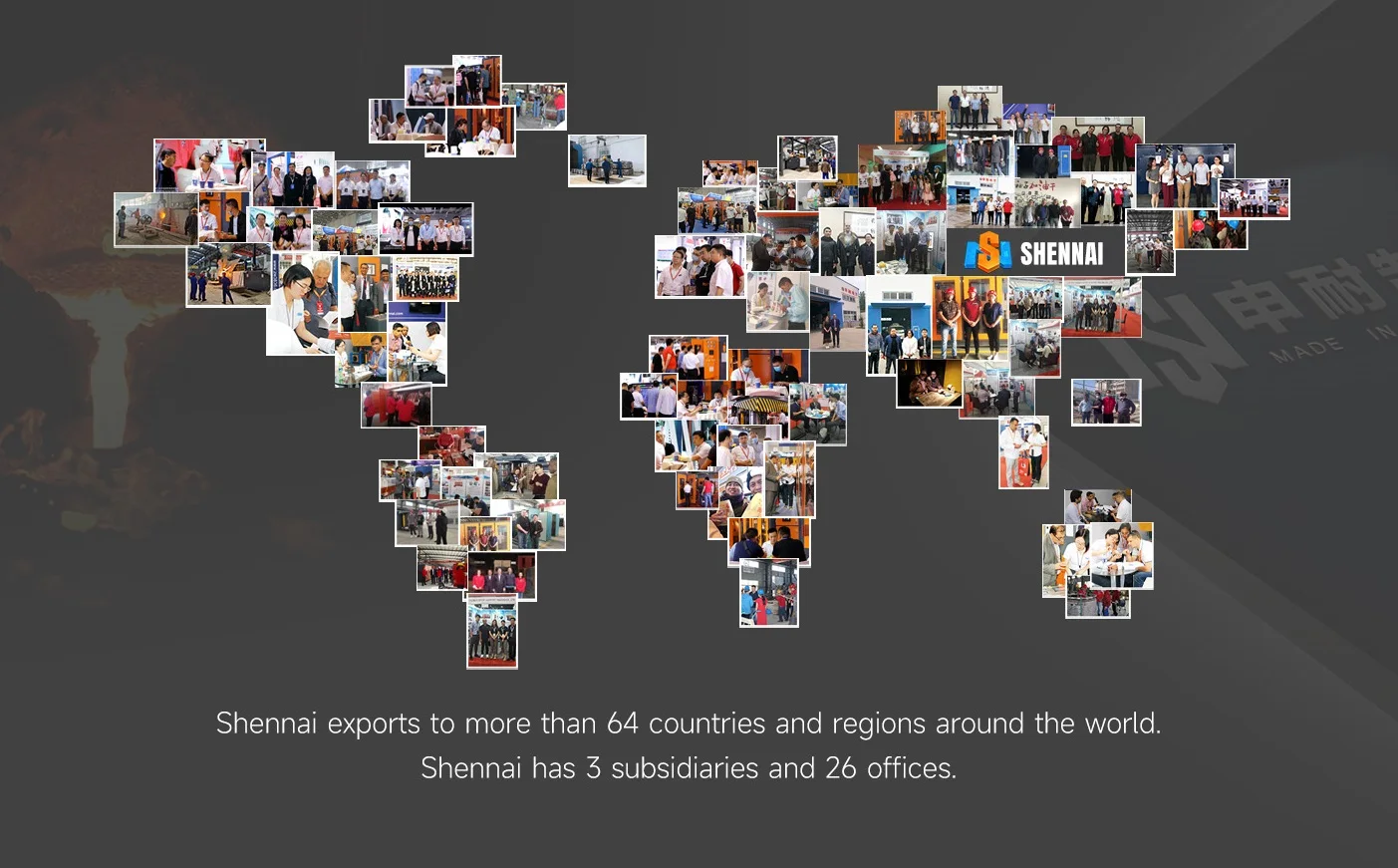

| Showroom Location | Saudi Arabia, Indonesia, Pakistan, India, Russia, South Korea, Romania, South Africa, Kazakhstan, Uzbekistan, Malaysia |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Energy & Mining, melting casting |

Product Detail

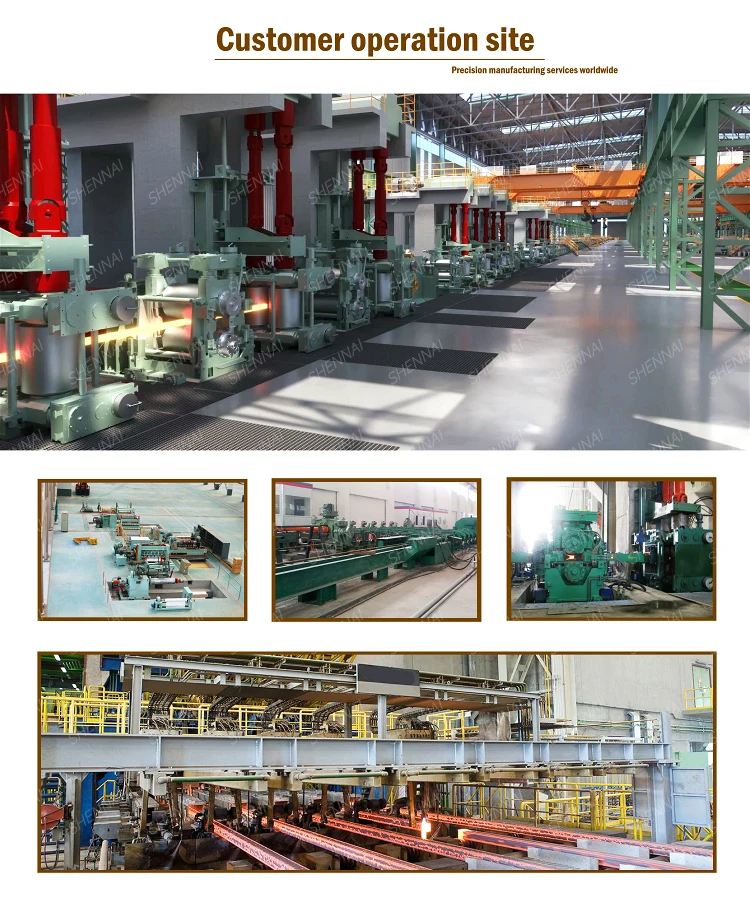

The steel roughing mill stand is used to reduce the thickness of the steel while extending the overall length. The rack of the rough rolling mill is an important part of the steel frame. The rack is equipped with a roll chock and a roll adjustment device. The rolling mill stand must have sufficient strength and rigidity to withstand the rolling force.

We can manufacture and provide complete rolling mills for rolling rebar/wire rod/structural steel (such as angle steel, I-beam, channel steel, steel plate, etc.).

| Model | φ550 | φ450 | φ350 |

| The diameter and length of barrel(mm) | φ425-φ660×80 | φ320-φ485×700 | φ280-φ390×600 |

| Roller neck size(mm) | φ280 | φ200 | φ180 |

| The Max rolling force (t) | 200-280 | 150 | 105 |

| Rollaxial adjustment | ±3mm | ±3mm | ±3mm |

| Max Opening size(mm) | 425~685 | 340~495 | 290~400 |

| Roll gap adjustment method | Hydraulic | Hydraulic | Hydraulic |

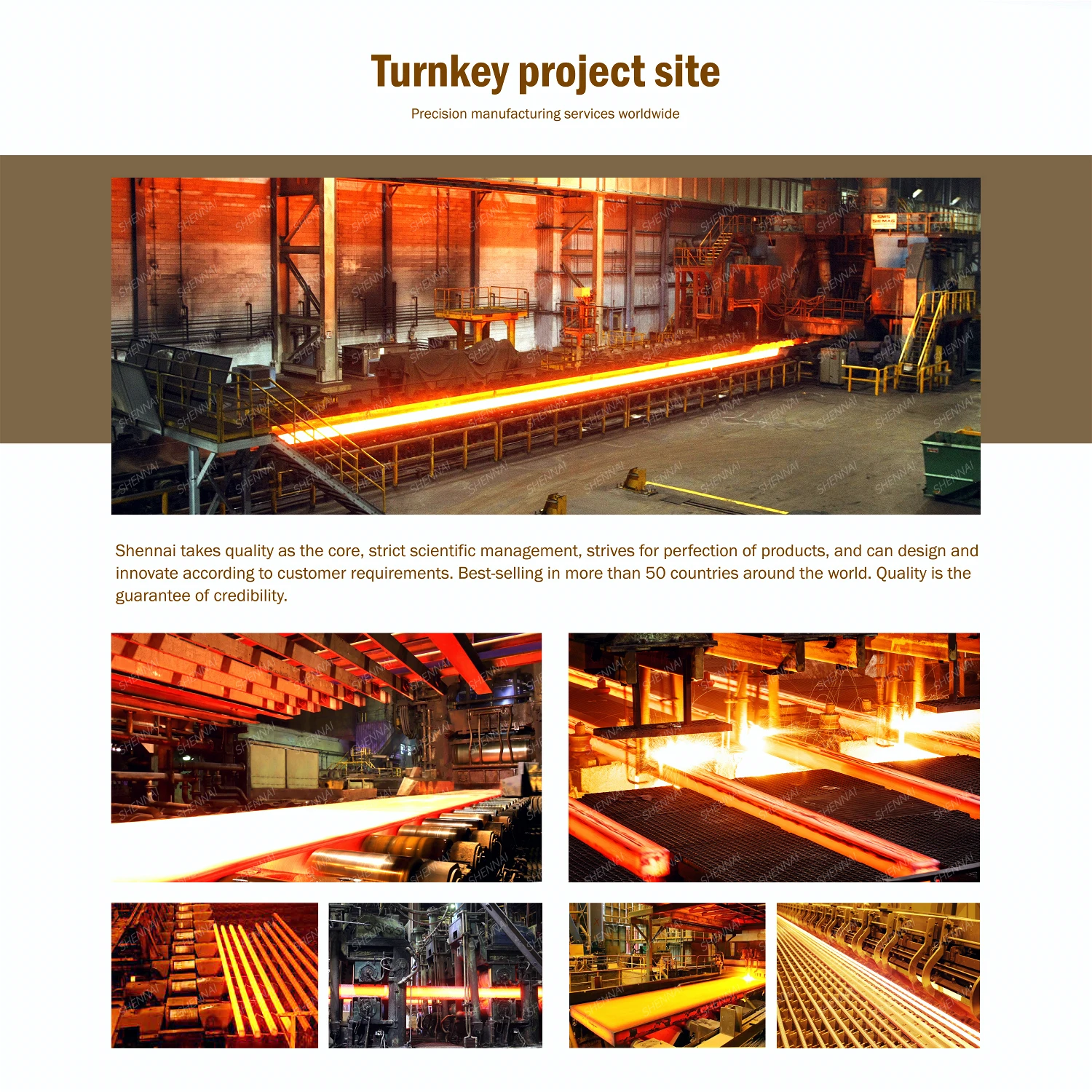

As a professional Steel Roughing Rolling Mill Stand manufacturer in China, we can supply designing, manufacturing, installation, and commission of the equipment with "turn-key" service. We can also design, manufacture and revamp other non-standard equipment according to the requirements of users.

Special Features of Steel Roughing Mill Stand:

- Fully automatic operation and heavy duty

- High strength and stiffness.

- Durable design which is suitable enduring heavy load.

- Complete stand of the Mill Stand is stress relieved and fully machined.

- Very convenient to change rolls quickly and easy maintenance, avoid more downtime.

- Bearing long life.

Service:

- We can provide foundation layout and arrangement diagram.

- Trustworthy after-sales service, we will send engineers to your factory to install and debug the machines.

- Competitive price & excellent quality.

- Our machines are easy operation and maintenance.

- Lower investment.

- Steady performance.

- Products are customized for different needs.

- Production capability can be adjusted according to customers' request.

- Low energy consumption.

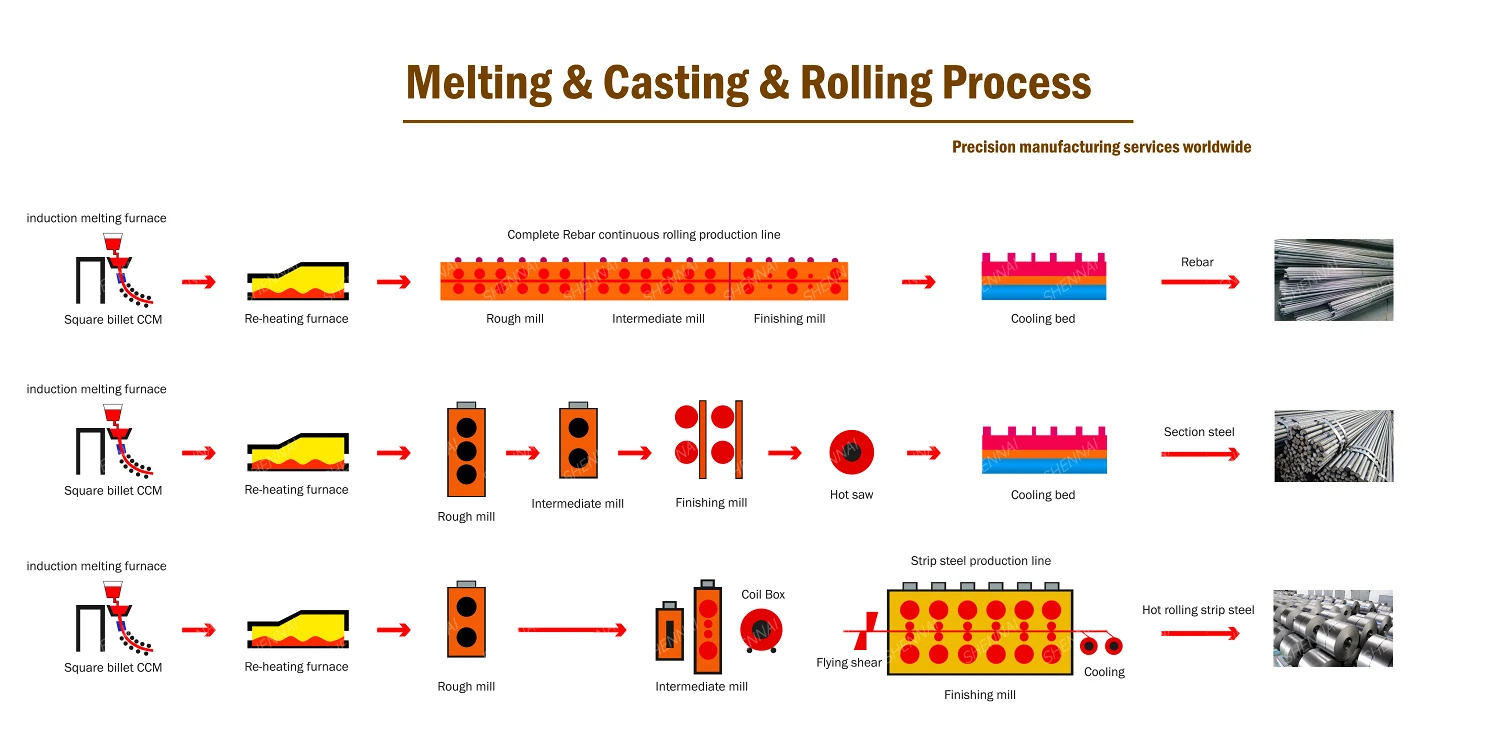

| Melting & Casting & Rolling Process |