99.99% 96.3% 95.5% 95% Fule Ethanol Bioethanol Equipment Alcohol Distillery Distillation Plant Line Turnkey Project

US $13,000.00-14,000.00 / set

1 set(s)Minimum order

processing:

Distilling

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump

place of origin:

Zhejiang, China

brand name:

ACE STILLS

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Distilling |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| place of origin | Zhejiang, China |

| brand name | ACE STILLS |

| model number | ACE-ZL-F601 |

| voltage | 110V/220V/380V/440V/480V |

| power(w) | 0-30KW |

| weight | 500 |

| dimension(l*w*h) | User Requirements |

| processing types | Wine Beer Alcohol Whiskey Vodka Gin Tequila Brandy |

| warranty | 1.5 years |

| Material | T2 copper/SS304/SS316 |

| Capacity | 200L-20,000L |

| Heating method | Electric Heating, Gas Heating,Steam heating |

| Application | Craft Spirit Production Line. |

| Spirits | Wine Whiskey Vodca Gin Tequila Brandy |

| Alcohol concentration | Maximum Alcohol 96% |

| Cleaning | CIP System |

| Welding | Arc Argon Protection |

| Tags | For Alcohol/For Beer/Reflux Stills |

| Showroom Location | Egypt |

Product Detail

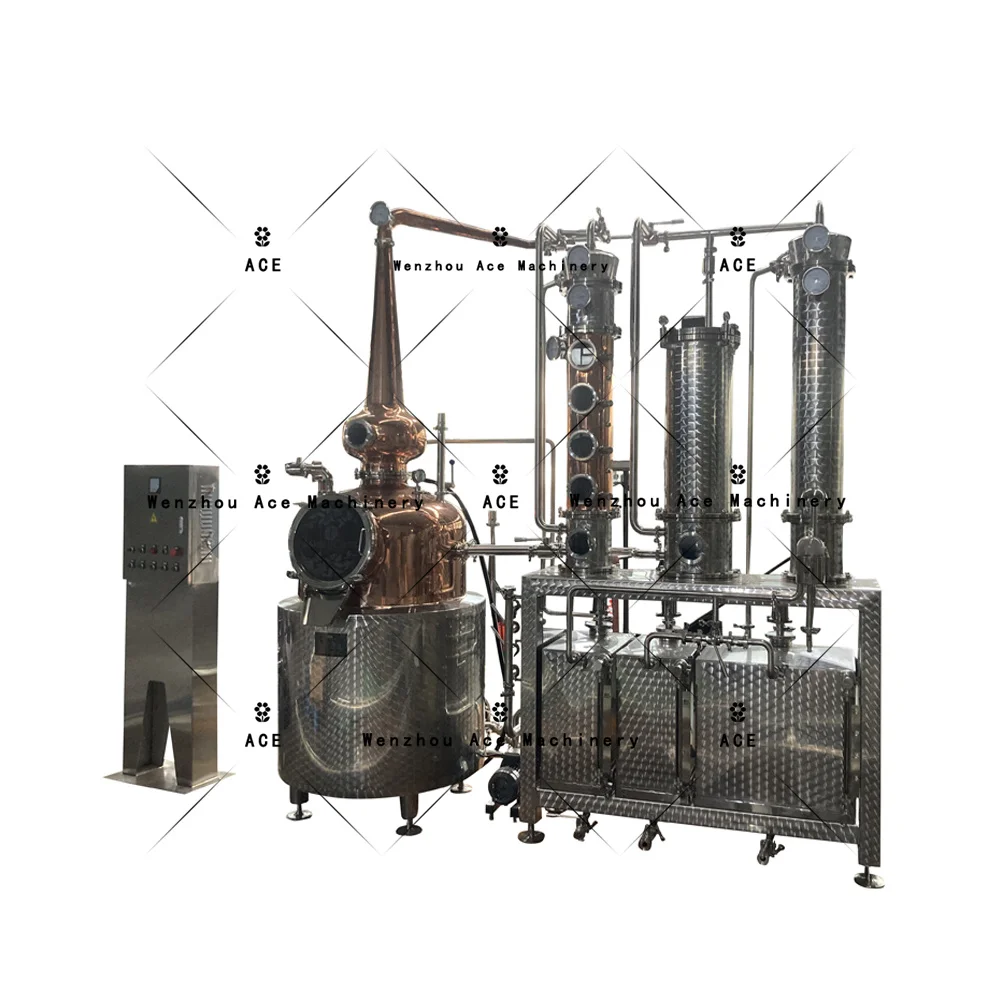

99.99% 96.3% 95.5% 95% Fule Ethanol Bioethanol Equipment Alcohol Distillery Distillation Plant Line Turnkey Project

Customized Commerce stills : Gin, vodka, whiskey, rum, brandy, tequila from 50L to 20,000L.

Fast Delivery.22 years of manufacturing experience.10-year warranty

Video

Products Description

We Can Make The Brewing Equipment For Beer, Wine, Sparkling Wine, Whiskey, Gin, Brandy, Rum Etc

The Equipment Capacity From 50L To 20,000L.

Beer Equipment: Including The Brew house, Fermentor, Brite Tank, Mash Tun, CIP Trolley Etc;

Wine Equipment: Including The Red Wine/White Wine/Sparkling Wine Tank, Floating Lid Wine Tank.

Distiller Equipment: Including The Rum/Whiskey/Brandy/Gin/Vodka Distillery Equipment

Pot Stills / Column Stills / Hybrid Stills

At ACE STILLS, we specialize in crafting premium copper stills to meet various distillation needs, from home distillation to craft breweries and professional distilleries. Our distillation units can be customized to do it all, whether you’re looking for a pot still, column still, or hybrid still.

Based on a typical pot still, we can customize it with column stills, gin baskets, doublers, and other devices to meet your distillation needs. Additionally, the shape of the helmet and the slope of the lyne arm can be tailored to suit the characteristics and distillation methods of desired spirits.

* Various distillation functions

* 99.58% pure copper

* Quality assurance

* 99.58% pure copper

* Quality assurance

Column

Manhole

Whiskey head

Basic Specifications

* The inner tank is made of TP2 copper and the wall thickness is 3mm/4mm/5mm/6mm

* Heating method: interlayer steam heating or electric heating optional

* Available size from 50L-5000L

* With or without a stirring motor

* Tower column: 6 sight glass 5 layers of trays

* Suitable for whiskey, gin, fruit brandy

* Whiskey copper head

* Stainless steel condenser

* Stainless steel gold blue

* Stainless steel collection tanks

* Stainless steel support

* CIP cleaning pump

Other specifications based on the different sizes and type of alcohol to make:

* The first column: 4 sight glasses and 4 layers of trays, with liquid level lever

* Second column: 8 sight glass 8-layer trays with liquid level lever

* The third column: 8 sight glasses 8 columns, with liquid level lever

* Drain port can be customized according to your needs

* Stainless Steel spirit Storage Tanks in sizes ranging from 50L-5000L

* Gin basket optional

* Heating method: interlayer steam heating or electric heating optional

* Available size from 50L-5000L

* With or without a stirring motor

* Tower column: 6 sight glass 5 layers of trays

* Suitable for whiskey, gin, fruit brandy

* Whiskey copper head

* Stainless steel condenser

* Stainless steel gold blue

* Stainless steel collection tanks

* Stainless steel support

* CIP cleaning pump

Other specifications based on the different sizes and type of alcohol to make:

* The first column: 4 sight glasses and 4 layers of trays, with liquid level lever

* Second column: 8 sight glass 8-layer trays with liquid level lever

* The third column: 8 sight glasses 8 columns, with liquid level lever

* Drain port can be customized according to your needs

* Stainless Steel spirit Storage Tanks in sizes ranging from 50L-5000L

* Gin basket optional

Why choose Ace stills to supply your distillery equipment?

Why choose Ace stills to supply your distillery equipment?

1. Turnkey Solution Purchase

Whether your budget for your craft distillery equipment is $2,000.00 or $100,000.00 we can set you up with a complete distilling

solution, from mashing, fermenting to distilling and storing, as well as the auxiliary machines.

2. High-grade Copper Material

All of our copper vessels are manufactured with high quality TP2 materials, are of the best quality of copper.

3. Copper Head Welding Process

The quick-installation and copper welding methods are one-time over-welding to ensure that the parts in contact with the alcohol

are made of copper, which is beautiful and generous; the sealing performance is due to the pressure resistance of the sealing

ring, without the influence of welding parts, thus improving the service life of the equipment.

4. Distillery Tower Process

The parts in contact with the alcohol are made of red copper, and the design process of tumbling is adopted.

1. Turnkey Solution Purchase

Whether your budget for your craft distillery equipment is $2,000.00 or $100,000.00 we can set you up with a complete distilling

solution, from mashing, fermenting to distilling and storing, as well as the auxiliary machines.

2. High-grade Copper Material

All of our copper vessels are manufactured with high quality TP2 materials, are of the best quality of copper.

3. Copper Head Welding Process

The quick-installation and copper welding methods are one-time over-welding to ensure that the parts in contact with the alcohol

are made of copper, which is beautiful and generous; the sealing performance is due to the pressure resistance of the sealing

ring, without the influence of welding parts, thus improving the service life of the equipment.

4. Distillery Tower Process

The parts in contact with the alcohol are made of red copper, and the design process of tumbling is adopted.

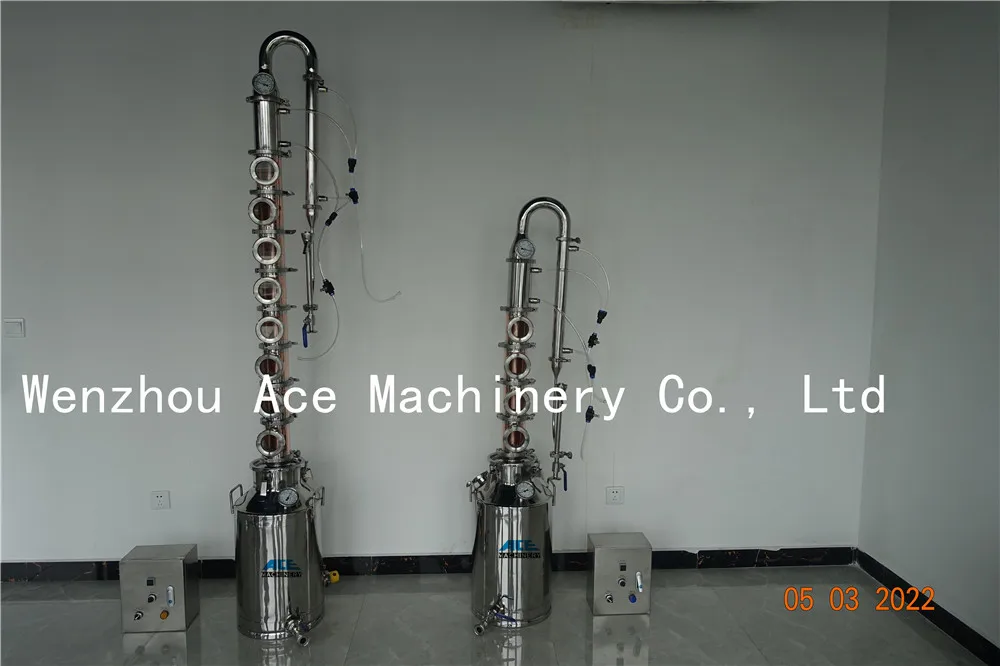

Home Moonshine Distillers

Main Features:

1. Any size available and customization service.

2. Home Distillation Equipment has a high wine yield, high alcohol purity and few impurities.

3. It is easy to operate and use, easy to clean and occupies a small area.

4. High safety, high work efficiency, long service life, low energy consumption, good quality and low price.

5. Mini Distillery looks good and beautiful, and can be used as an ornament.

6. The material is safe and assured. Food grade stainless steel and copper are used.

7. Operation guide and drawings can be provided.

8. Wide range of uses,can make whiskey, brandy, rum, vodka and other alcohol to meet your needs.

Customer case

Brewing equipment

Beer Fermentation Tank

• Beer Fermentation Tank has 200L and 30,000L and otherpecifications, according to the actual requirment of customers.

• Cone bottom shape, cooling jacket using dimple jacketjacketed outside covered with insulation, thermal insulationmaterial for polyurethane (cold).

• Connector using tri-clamp, inner tank using SS304 or S316L the inner surface mirror polishing Ra≤0.4um-0.6um. Outersurface can be polished, wiredrawn, sandblasted according tocustomers requirement.

Stainless steel beer fermenter | ||

Structure: | 1.Volume from 100L-30000L,could be customized according to customer needs. | |

2.Material use sanitary stainless steel. | ||

3.Three layer structure:Inner body,Jacket and isolation.Isolation layer filled with insulation material. | ||

4.Inner wall fineness less than 0.6um,outside finish could be matt or mirror polish | ||

5.Conical bottom shape,cooling jacket could adopt dimple jacket,arched and corrugated access jacket. | ||

6.All pipes are all ISO or DIN sanitaty pipe,internal and external adopt food grade mirror polish | ||

7.PLC control system,which could achieve automatic,semi automatic control,to ensure the accurately and effectively of parameters and experimental results. | ||

Parts(optional): | 1.Manhole 2.Aseptic breather 3.Thermometer(As customer request) 4.CIP Spray ball 5.Bacterial access port 6.Agitator 7.Adjustable leg 8.Jacket(Dimple or full jacket as customer request) | |

Bright Tank

The bright tanks are cans for storing live beer. After the beer is fermented and matured, the yeast and another turbidity in the fermentation broth need to be filtered to make the wine clear and bright. After the fermentation broth is filtered, it is called "bright beer". Let the packaging department bottling into beer finished products. Sake jars are used to hold sake.

In most breweries, the beer will be filtered after leaving the larger container and sent into bright tanks. If you want to force carbonation of bright beer, the beer can be carbonated in a fermentation tank or storage tank. In this case, the beer should be completely filled with carbonic acid to reach the bright tank.

Vertical

Horizontal

Wine Fermentation Tank

1. Used as storage and fermentation tank in wine industries

2. Volume from 50L-30000L, could be customized according to customer needs

3. Material use sanitary stainless steel.

4. Conical bottom shape, cooling jacket could adopt dimple jacket, arched and corrugated access jacket.

5. PLC/PID control system, which could achieve automatic, semi-automatic control, to ensure the accurately and effectively of

parameters and experimental results.

Fermentor with agitator

Flat Bottom Wine Fermenter

Packaging & Shipping

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend, and we sincerely do business and make friends with them, no matter where they come from.