Australia Rock Stone Grate Ball Mill Laboratory Testing Machine 900*1200 Grinding Ball Mill for Mineral Separation

US $6,300.00-6,900.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Engine, motor

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

0.2-0.8

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine, motor |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 0.2-0.8 |

| Place of Origin | Jiangxi, China |

| Brand Name | Jiangxi Henghong |

| Dimension(L*W*H) | 5500*1950*2500 |

| Weight | 5800 KG |

| Warranty | 1 Year |

| Product name | Laboratory Testing Machine |

| Feeding Size | 25mm |

| Load steel balls weight | 1.5 Tons |

| Output size | 2-0.074mm |

| Price | Negotiable before order |

| MOQ | 1Set |

| Color | As your requirements |

| Keywords | Laboratory Testing Machine,Stone Grate Ball Mill,Grinding Ball Mill |

| Grinding material | Metal ores, non-metallic ores, cement clinker, slag, quartz sand etc |

| Factory Visit | Welcomed Warmly |

| Showroom Location | Egypt, Turkey, United States, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Morocco, Chile, UAE, South Africa, Kazakhstan, Nigeria, Uzbekistan, Malaysia, Australia, Sudan |

| Warranty of core components | 1 Year |

| Condition | New |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining, Gold Processing Plant, Energy & Mineral |

| Marketing Type | Hot Product 2024 |

Product Detail

Wholesale Price Wet and Dry Type 1 Ton per Hour Stone Rock Gold Mineral Ore Grinding 900*1800 Small Ball Mill With Rubber Liner

Jiangxi Henghong mining machinery is devoting to provide turnkey solution with worldwide clients for mineral processing plant including research, design, manufacture,installation and commissioning, personnel training, after-sale service and management of processing plant. Up to now, we have developed five major product lines: they are mining crushing machine, mining milling machine,mining classifying separator, mining flotation machine and the mining gravity separator. When you find us, you find one best mining machinery manufacturer.

Small Ball Mill Introduction

Ball mill is a key equipment to grind the crushed materials,it widely used in powder-making production line including mineral,cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type.

There are two kinds of ball mill, grid type and overflow type due to different ways of discharging material.

There are two kinds of ball mill, grid type and overflow type due to different ways of discharging material.

900*1800 Ball Mill

900*3000 Ball Mill

1200*4500 Ball Mill

Product Parameters

Model | Cylinder Size (mm) | Revolution of cylinder | Weight with balls | Feeding Size | Capacity | Power | Weight | ||

Diameter | Length | (r/min) | (t) | (mm) | (t/h) | (kw) | (kg) | ||

GM0912 | 900 | 1200 | 41.6 | 1.1 | 25 | 0.3~0.9 | 11 | 4210 | |

GM0921 | 900 | 2100 | 41.6 | 1.8 | 25 | 0.6~1.5 | 15 | 6660 | |

GM1224 | 1200 | 2400 | 35.1 | 4 | 0~25 | 1.6~4.1 | 37 | 10020 | |

GM1228 | 1200 | 2800 | 35.1 | 4.6 | 0~25 | 1.9~4.8 | 45 | 10935 | |

GM1232 | 1200 | 3200 | 35.1 | 5.3 | 0~25 | 2.2~5.5 | 45 | 11230 | |

GM1245 | 1200 | 4500 | 30.2 | 6.8 | 0~25 | 3.3~8.2 | 55 | 13210 | |

GM1324 | 1300 | 2400 | 30.2 | 4.5 | 0~25 | 1.5~3.5 | 37 | 10210 | |

GM1328 | 1300 | 2800 | 30.2 | 5.2 | 0~25 | 1.7~4.4 | 45 | 11290 | |

GM1334 | 1300 | 3400 | 30.7 | 6.2 | 0~25 | 2.0~5.2 | 75 | 13111 | |

GM1524 | 1500 | 2400 | 30.7 | 5.8 | 0~25 | 2.3~5.7 | 55 | 15430 | |

GM1530 | 1500 | 3000 | 30.7 | 7.3 | 0~25 | 3.1~7.3 | 75 | 16843 | |

GM1533 | 1500 | 3300 | 30.7 | 8 | 0~25 | 3.5~8.0 | 80 | 17849 | |

GM1536 | 1500 | 3600 | 30.7 | 8.7 | 0~25 | 3.9~8.8 | 80 | 18649 | |

GM1542 | 1500 | 4200 | 30.7 | 10.2 | 0~25 | 4.3~9.4 | 110 | 19330 | |

GM1545 | 1500 | 4500 | 30.7 | 10.9 | 0~25 | 4.8~10.8 | 110 | 20000 | |

GM1557 | 1500 | 5700 | 30.7 | 13.8 | 0~25 | 6.1~14 | 130 | 23597 | |

GM1563 | 1500 | 6300 | 30.7 | 15.3 | 0~25 | 6.5~15 | 155 | 24390 | |

GM1830 | 1800 | 3000 | 25.04 | 10.8 | 0~25 | 2.4~10 | 130 | 24490 | |

GM1834 | 1800 | 3400 | 25.04 | 12.3 | 0~25 | 2.6~11 | 155 | 30390 | |

GM1836 | 1800 | 3600 | 25.04 | 13 | 0~25 | 2.7~12 | 155 | 31600 | |

GM1842 | 1800 | 4200 | 25.04 | 15.2 | 0~25 | 3.3~15 | 180 | 33490 | |

GM1864 | 1800 | 6400 | 25.04 | 23.2 | 0~25 | 5.1~23 | 210 | 42440 | |

GM2130 | 2100 | 3000 | 23.8 | 14.3 | 0~25 | 4.0~30 | 180 | 41960 | |

GM2136 | 2100 | 3600 | 23.8 | 17.1 | 0~25 | 5.0~37 | 180 | 44550 | |

GM2140 | 2100 | 4000 | 23.8 | 19.1 | 0~25 | 5.2~39 | 245 | 46690 | |

GM2145 | 2100 | 4500 | 23.8 | 21.4 | 0~25 | 5.6~42 | 245 | 49230 | |

GM2170 | 2100 | 7000 | 23.8 | 29.2 | 0~25 | 5.9~80 | 380 | 59610 | |

GM2265 | 2200 | 6500 | 21.4 | 34 | 0~25 | 6~67 | 380 | 64800 | |

GM2436 | 2400 | 3600 | 23 | 20.6 | 0~25 | 6.4~81.5 | 280 | 63680 | |

GM2445 | 2400 | 4500 | 23 | 25.1 | 0~25 | 7.9~99.2 | 380 | 72280 | |

GM2464 | 2400 | 6400 | 23 | 36.7 | 0~25 | 11.2~131 | 475 | 86180 | |

GM2736 | 2700 | 3600 | 21.7 | 28.4 | 0~25 | 15~115 | 475 | 88400 | |

GM2742 | 2700 | 4200 | 21.7 | 33.1 | 0~25 | 17.5~135 | 570 | 90420 | |

Working Principle

Working Principle: Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Main Features

♦ Energy-saving & Large application range.

♦ Simple structure with long working life

♦ Less wearing parts, small operation and maintenance cost

♦ Two types feeders: combined feeder and cylinder feeder

♦ Less wearing parts, small operation and maintenance cost

♦ Two types feeders: combined feeder and cylinder feeder

♦ Barrel lining and grinding media can apply various abrasive materials

♦ Dry ball mills & wet ball mills for option according to different materials & discharging methods

♦ Dry ball mills & wet ball mills for option according to different materials & discharging methods

Our Workshop

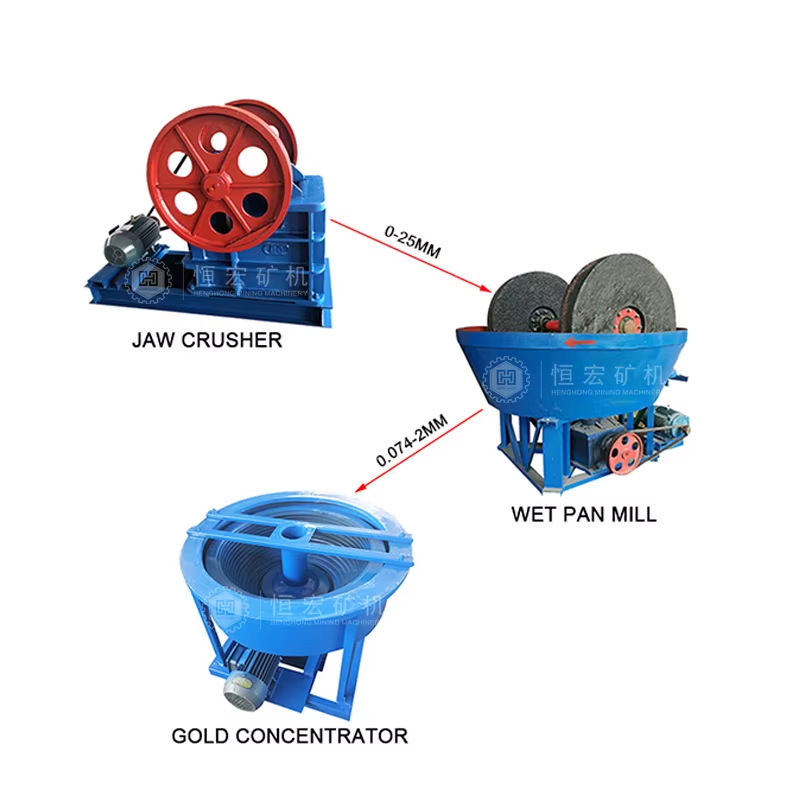

Project Flowchart

Packing & Delivery

Shipping Way:

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity (LCL or FCL), container have 20GP/40GP/40HQ etc;

※ Other ways as customer requested (such as the buyer can arrange their own cooperated forwarder to pick up the goods from our factory).

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity (LCL or FCL), container have 20GP/40GP/40HQ etc;

※ Other ways as customer requested (such as the buyer can arrange their own cooperated forwarder to pick up the goods from our factory).

Successful Project

Ball Mill Project in Zimbabwe

Ball Mill Project in Uzbekistan

Ball Mill Project in Peru

Ball Mill Project in Thailand

Ball Mill Project in Mexico

Ball Mill Project in Indonesia

Ball Mill Project in Sudan

Ball Mill Project in Mongolia

Ball Mill Project in Australia

Related Products

FAQ

Q1: Are you manufacturer or trade company?

A1: We are One-stop service and original manufacturer has more than 40 years history in China.

Q2: What's your major products?

A2: Our products have been sold to all over the world, they are ball mill, wet pan mill, jaw crusher, hammer crusher, shaking table, centrifugal concentrator, jig machine, spiral chute, flotation machine, magnetic separator, sand washing machine, gold smelting furnace, belt conveyor, slurry pump etc.

Q3: How will you help the customer to install the equipment?

#1 Our senior engineer will supply installation and training service on-line or on-site.

#2 We have engineer in Southeast Asia and Africa, we can supply 7*24 service.

Q4: What about after-sale service?

A4: 18 months warranty for all kinds of products.

Q5: How long is your delivery time?

A5: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: What about the payment method?

A6: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

A5: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: What about the payment method?

A6: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q7: How to get the free solution and quotation?

A7: Please send inquiry to us on Alibaba, or please scan and add us as below picture, our sales manager will contact you ASAP.