Automatic Alcohol / Liquid Yogurt Filling and Packaging and Small Bag Multifunctional Packaging Machines

Other recommendations for your business

Contact us

Quik Detail

| production capacity | 20bag/min |

|---|---|

| Weight (KG) | 80 |

| function | FILLING, Sealing |

| application | Food, Beverage |

| packaging type | Bags, Film, Foil, Pouch |

| packaging material | Plastic |

| automatic grade | Automatic |

| driven type | Pneumatic |

| Voltage | 220V/110V |

| place of origin | Fujian, China |

| brand name | Link |

| dimension(l*w*h) | 540*1170*1530mm |

| warranty | 1 Year |

| key selling points | Easy to Operate |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, Pressure vessel, Pump, Gear, Bearing, Engine, Gearbox |

| Product name | ice lolly ice pop Ice Candy Ice Popsicle liquid sachet packing machine |

| Bag width | 50-240mm Custom |

| Bag length | 160mm Adjustable |

| Bag type | 3 Sides Seal/Back Seal available |

| Film material | Plastic, foil, filter paper, non-woven etc. |

| Packing speed | About 10-20 Bags/min |

| Machine material | SS304/SS316 Available |

| Machine type | Vertical Automatic Packing Machine |

| Main Function | Weighing Forming Filling Sealing |

| After-sale | After-sale Team Support |

| Type | Multi-Function Packaging Machine |

| Applicable Industries | Food & Beverage Factory, Farms, Home Use, Retail, Food Shop, Food & Beverage Shops, Other |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

| Condition | New |

| Warranty of core components | 1 Year |

Product Detail

Sealing Type | Three-side sealing / Back sealing |

Weighting Range | 1-100g (±0.2g) |

Film Width Range | 50-200mm |

Bag Length Range | 20-160mm |

Power Supply | 220V/110V |

Plug Type | Custom your country plug |

Machine Dimension | 540*1170*1530mm |

Packing Dimension (2 Case) | 1230*600 *1330mm |

Power Consumption | 350W |

Machine Weight | 90 KG |

Pls leave your detailed demands:

1. Double film hanging Frame. more stable , and film run more faster.

2. Extra vibration function for bag former. To make the product run more fluently, not easy to get stucked when pass though the

bag former.

3. The sealing aluminum block is Teflon, to make the finished bag no stick on the sealing mold , more faster.

4. Customer special voltage, and plug,make sure 100% meet customer's local use.

5. Use similar product to test machine before shipment to ensure that the machine is 100% Ok and suitable fore customer's product

, weight and bag size.

6. Professional international after-sales service, our engineers communicate in English and respond within 5 minutes.

7. Send replacement parts for future use.

8. New updated panel , easy to operatemachine from

other supplier :

1. single frame, save some material cost. not stable , film run slower.

2. no extra vibration function for bag former, if need , add more RMB200.

3.the sealing aluminum block , no teflon coating.If need , add more RMB100.

4. all china standard voltage and plug , if need to change , add more RMB200.

5. no machine test before delivery.

6. no special after seales service.

7. if need replace parts add more cost.

8. old button panel , not easy opearte.

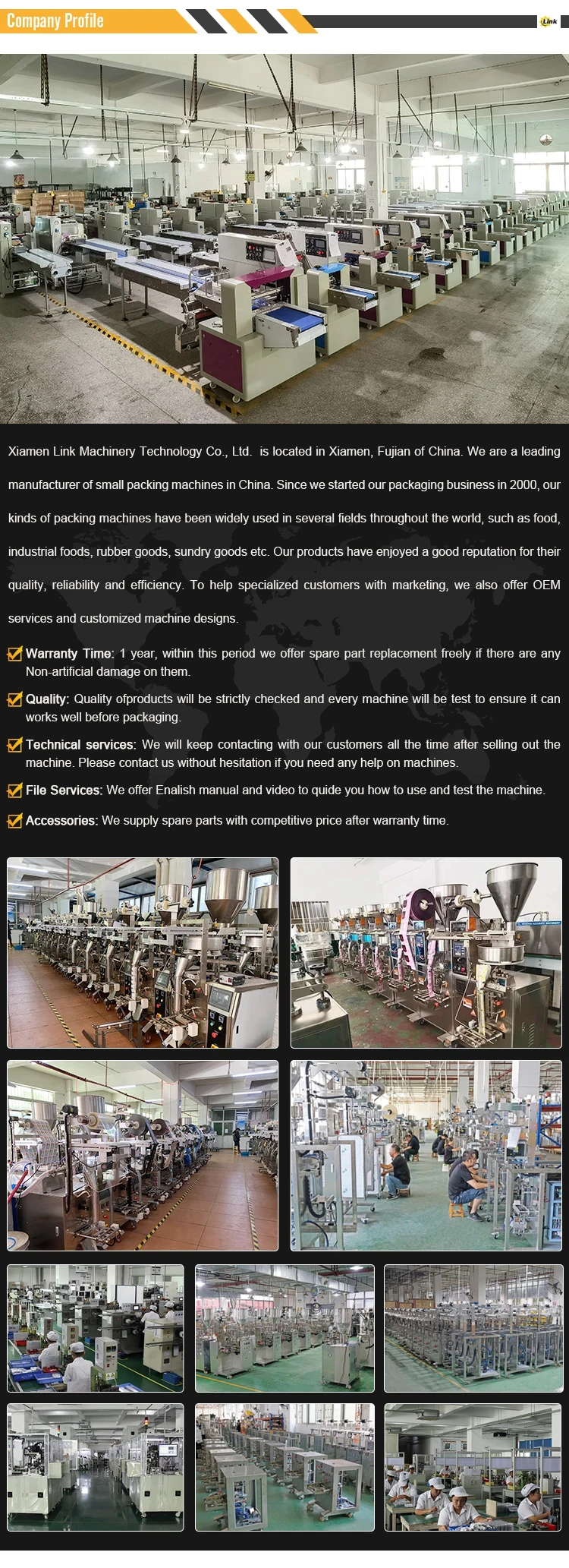

A:We are a manufacturer with a history of 25 years, with our own production team and after-sales team.

Q: how to place an order?

A: Before you buy the machine, please confirm all the details with us and we will sign the contract for you. We support letter of credit, telegraphic transfer, PayPal, Western Union and other printing machines.

Q: how will this machine be transported to my country? Can it be delivered to your door?

A:Yes, we can ship, air and express. Transportation costs vary according to different modes of transportation.

Q: How to make the machine work normally after receiving?

A: we will provide the installation video, operation manual and online support of the machine. You can follow our steps to install the machine. We have overseas engineers in some countries

Q: What if the machine doesn't work or breaks down during use?

A: Each machine must pass the packaging test before leaving the factory. If there is any problem with the machine, please contactus in time. We have a professional after-sales technical team to help you solve the problems of the machine.

Q: what is machine quality assurance?

A: One year limited warranty and lifelong technical support

Q: is the machine well packed and easily damaged?

A: we will use foam + carton + export wooden box to pack large machinery to avoid damage during transportation.

Q: do you accept customization?

A: Yes, we can customize the machine according to your requirements.