Automatic Multi-Size Steel Shelf Pallet Racking Roll Forming Machine Production Line for South Africa

US $58,000.00-60,000.00 / set

1 set(s)Minimum order

Type:

Roll Forming Machine

Tile Type:

Steel

Place of Origin:

HeBei,China

Brand Name:

ZTRFM

Voltage:

380V, 380V 50Hz 3Phase

Dimension(L*W*H):

8.5*1.65*1.5M

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Roll Forming Machine |

|---|---|

| Tile Type | Steel |

| Place of Origin | HeBei,China |

| Brand Name | ZTRFM |

| Voltage | 380V, 380V 50Hz 3Phase |

| Dimension(L*W*H) | 8.5*1.65*1.5M |

| Weight | 15500 kg |

| Warranty | 2 years |

| Key Selling Points | High Safety Level |

| Rolling thinckness | 0.4-0.7mm |

| Feeding width | 410mm 510mm 610mm 710mm |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | motor, Other, Bearing, Gear |

| Certification | CE/ISO9001 |

| Keywords | shelf panel roll forming machine |

| Control system | PLC Control |

| Forming Speed | 10 m/min |

Product Detail

Product Description

Automatic Multi-Size Steel Shelf Pallet Racking Roll Forming Machine Production Line for South Africa

SPECIFICATIONS & EQUIPMENT

Automatic roll forming and cutting with Inverter, PLC, HMI

Automatic programmable length settings via the touch panel

Customize design

Supermarket Storage Rack Panel Roll Forming Machine

ZTRFM specializes in designing and manufacturing advanced metal forming equipment, incorporating cutting-edge, patented technologies for companies producing shelf and pallet racking systems. Their roll forming equipment and systems are commonly used to produce pallet rack uprights, step beams, and steel shelving. These components are typically manufactured by both OEM producers and job shop manufacturers.

For businesses that currently form components using press brakes in small volumes, ZTRFM's solutions provide an efficient pathway to transition to roll forming, offering significant productivity improvements. With extensive engineering expertise, ZTRFM delivers flexible solutions tailored to meet the precise tolerances required for modern shelf and pallet rack applications.

ZTRFM specializes in designing and manufacturing advanced metal forming equipment, incorporating cutting-edge, patented technologies for companies producing shelf and pallet racking systems. Their roll forming equipment and systems are commonly used to produce pallet rack uprights, step beams, and steel shelving. These components are typically manufactured by both OEM producers and job shop manufacturers.

For businesses that currently form components using press brakes in small volumes, ZTRFM's solutions provide an efficient pathway to transition to roll forming, offering significant productivity improvements. With extensive engineering expertise, ZTRFM delivers flexible solutions tailored to meet the precise tolerances required for modern shelf and pallet rack applications.

This machine‘’s finished product and application for your reference

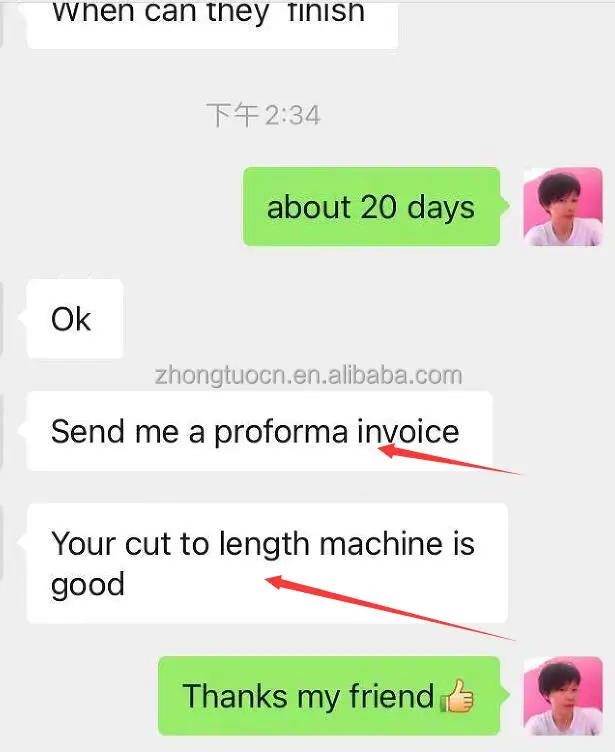

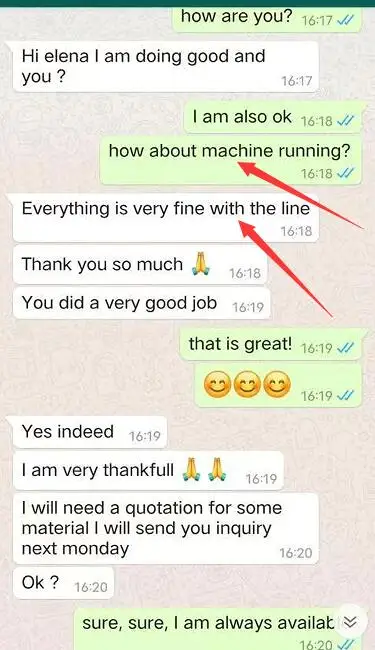

How customer say about us?

Steel Shelf Pallet Racking Roll Forming Machine | ||||||||

1.Formed Material | PPGI,GI,AI | Thickness:0.4-0.7mm | ||||||

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||||||

3.Main body | Roller station | 20 rows(As your requirement) | ||||||

Diameter of shaft | 50mm solid shaft | |||||||

Material of rollers | Cr12MoV,with vacuum heat treatment,twice tempering,hardness HRC55-58 | |||||||

Machine body frame | 350 H steel | |||||||

Drive | Gear transmission | |||||||

Dimension(L*W*H) | customize | |||||||

Weight | 15T | |||||||

4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||||||

5.Power | Motor Power | 5.5KW | ||||||

Hydraulic system power | 5.5KW | |||||||

6.Voltage | 380V 50Hz 3Phase | As your requirement | ||||||

7.Control system | Electric Box | Customized(famous brand) | ||||||

Language | English(Support multiple languages) | |||||||

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||||||

18.Forming Speed | 10-20m/min | The speed depends on the shape of the tile and the thickness of the material. | ||||||

Products Display

Feeding device

With hydraulic pre-cutting,and handwheels for adjust for feeding material.

Roll forming device

rollers after thick chromed and quenched for good hardness.

High precision Hydraulic cutting device

Gear and chain drive

PLC control cabinet

Adopted Aviation plug for buyer easy installation,touch screen for easy adjust.

Hydraulic station

With cooling fun for long service time.

Recommend Products

Why Choose Us

Company Profile

Product packaging