CJSE 17.7bar 5 Ton lpg tank and Skid Unit lpg Skid Station for Sale

US $13,500.00-16,800.00 / set

1 set(s)Minimum order

place of origin:

Shandong, China

brand name:

CJSE

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

Pressure vessel

dimension(l*w*h):

9.5 x 2 x 2.3m

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Shandong, China |

|---|---|

| brand name | CJSE |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | Pressure vessel |

| dimension(l*w*h) | 9.5 x 2 x 2.3m |

| volume (m³) | 5 - 200 |

| inner material | Q345R |

| outer material | Q345R |

| Design Pressure (mpa) | 1.77 |

| design standard | GB150/ASME |

| working temperature(℃) | -19 - 50 ℃ |

| warranty | 1 Year |

| key selling points | High Productivity |

| LPG Tank Type | Mobile petrol fuel station 5ton skid lpg station with dispenser |

| LPG Tank Working Pressure | 1.63MPa |

| LPG Tank Design Pressure | 1.77MPa |

| LPG Tank Materials | Q345R carbon steel |

| LPG Tank Length | 9334mm |

| LPG Tank Standard | GB150/ASME |

| LPG Tank Color | netural grey or silver |

| Capacity Available for tank | 5m3 to 200m3 LPG Filling Plant 5 Ton |

| Processing for LPG Tank | heat treatment/shot blast/X-ray detection |

| LPG Tank Applications | for lpg storage |

| Condition | New |

| Warranty of core components | 1 Year |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location | France, Peru, Saudi Arabia, Indonesia, Russia, Thailand, Chile, Colombia, Sri Lanka, Romania, Kyrgyzstan, Nigeria, Australia, Morocco |

| Marketing Type | New Product 2023 |

| Capacity | 5 - 200 |

| Weight | 8700 |

| Max Working Pressure(MPa) | 1.82 |

Product Detail

Product Brief Description >>>

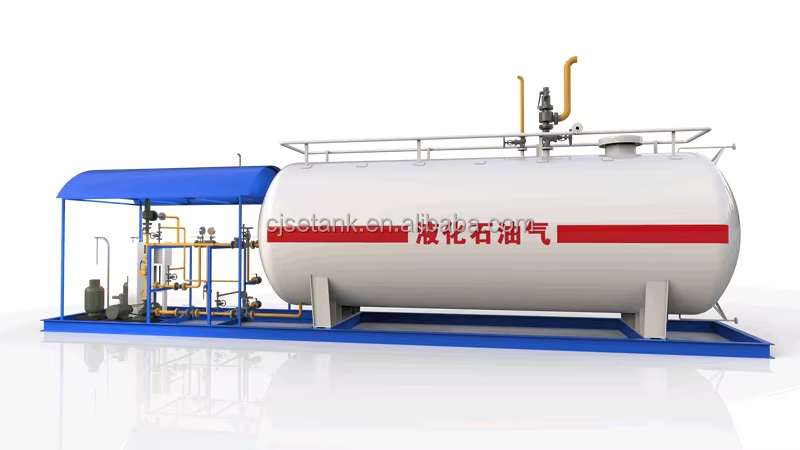

The LPG skid mounted filling station is an integrated equipment that integrates LPG storage tanks, pumps, motors, pipelines, valves and filling machine. Skid station can fill cylinders with LPG like large LPG stations, and it can also fill vehicles with LPG.

Technical Advantages >>>

1. Cost Effective

If you are an individual or your company is just starting. the fund is insufficient, but you are very optimistic about LPG

industry. LPG skid station is your best choice. It needs at least USD 7,000,000 to invest a LPG station. While a LPG skid station costs only USD15,000.

2. Easy operation

It is very flexible in use, integrally skid-mounted, has all the basic filling functions and safety devices.

3. No on-site installation, ready to use when you receive it

It has little on-site installation work, and is not challenged by traditional on-site construction conditions (such as material

delays, adverse weather, and other project slow-downs), resulting in Reduce investment costs by up to 75% or more.

The LPG skid mounted filling station is an integrated equipment that integrates LPG storage tanks, pumps, motors, pipelines, valves and filling machine. Skid station can fill cylinders with LPG like large LPG stations, and it can also fill vehicles with LPG.

Technical Advantages >>>

1. Cost Effective

If you are an individual or your company is just starting. the fund is insufficient, but you are very optimistic about LPG

industry. LPG skid station is your best choice. It needs at least USD 7,000,000 to invest a LPG station. While a LPG skid station costs only USD15,000.

2. Easy operation

It is very flexible in use, integrally skid-mounted, has all the basic filling functions and safety devices.

3. No on-site installation, ready to use when you receive it

It has little on-site installation work, and is not challenged by traditional on-site construction conditions (such as material

delays, adverse weather, and other project slow-downs), resulting in Reduce investment costs by up to 75% or more.

4. Small Land Occupation

A 5m3 skid station covers an area of only 12 square meters. Suitable for complex terrain.

5. Convenient mobility

It can be relocated to another location at any time after finishing work in one location, and is a very convenient portable gas supply point. For example, some engineering projects may need to be relocated to other locations within a few months, and the skid-mounted station can be easily transferred with the project.

6. Safety devices

A 5m3 skid station covers an area of only 12 square meters. Suitable for complex terrain.

5. Convenient mobility

It can be relocated to another location at any time after finishing work in one location, and is a very convenient portable gas supply point. For example, some engineering projects may need to be relocated to other locations within a few months, and the skid-mounted station can be easily transferred with the project.

6. Safety devices

Our self-developed skid-mounted station, in addition to the basic functions of unloading and vehicles & cylinders filling, also adds advanced functions such as discharging residue, transferring the liquid into another tank, filling tanker, safety relief, leakage alarm, and electric control operation.

<<<GET QUOTE LEARN MORE>>>

Effect Drawing >>>

Product Parameter

Medium | LPG | ||

LPG Storage Tank | Capacity | 2.5 ton to 30 ton | |

Design pressure | 1.77MPa | ||

Design temperature | -20℃/50℃ | ||

Material | Q345R | ||

Filling ratio | 0.9 | ||

Electronic filling scale | Filling range | 2-120KG | |

Working power | 220V,50HZ | ||

Power | 30W | ||

Max.Filling weight | 150KG | ||

Min.Filling weight | 1KG | ||

Scale | 50G | ||

Precision grade | Ⅲ | ||

Working temperature | -40℃〜50℃ | ||

Working hunidity | Relative humidity≤90% | ||

Working pressure | 1.6MPa | ||

Scale size | 535×425MM | ||

Explosion proof indication | Exdeib ⅡBT4GB | ||

Filling range | 2-120KG | ||

Pump | Pated flow | 8-12M³/H | |

Maximum lift | 150M | ||

Maximum suction head | 12M | ||

Working power supply | AC380V,50HZ | ||

Power | 4-7.5KW | ||

Design pressure of process pipeline | 2.5MPa | ||

Opening pressure of safety valve in process pipeline | 1.70MPa | ||

Applicable range of temperature | -20℃〜50℃ | ||

Applicable range of humidity | 10〜95% | ||

Skid size(L)× wide × high | It depends on the user | ||

Total weight | It depends on the user | ||

Customer Cases

Products Shipment

We offer a diverse range of transportation options, including bulk cargo shipping and container shipping. For bulk cargo shipping, we use tarpaulins and cargo nets to package the tanks, ensuring moisture and corrosion resistance, providing worry-free safety. You can choose from ocean shipping, land transportation, or railway transportation based on your needs.

<<<GET QUOTE LEARN MORE>>>

Company Profile

Shandong Zhongjie Pressure Equipment Co.,Ltd.(CJSE) was founded in 2001, located at 2218 Jinan Road,Luxi New Area, Heze, Shandong, China.The company has 4 factories, covering a total area of more than 250,000 square meters, can undertake 100 tanks of 200 cubic meters each at a time. The main workshop area of more than 70,000 square meters and currently employs more than 1,000 staff, including 247 engineering and technical personnel, and 82 senior technical personnel.

The company highly focuses on the green energy pressure equipment industry,the leading products are: LPG Tank, Liquid Ammonia Storage Tank, LNG Tank, LO2, LN2 and LAr Tank, LCO2 storage tanks and other vacuum insulated cryogenic pressure vessels; Oil(Gas)fired boiler,Thermal Oil boiler,Biomass Boiler,Waste Heat boiler etc; Denitration engineering equipment,Thermal energy storage equipment,Complete set of chemical equipment and other pressure vessel products, Ground(Water)Source Heat Pump, Air Source Heat Pump, Water-cooled screw unit,Air cooling module and other central air conditioning HVAC equipment.The planned products include large-scale thermal energy center,LNG transport vehicle,LNG tank container and other high-end green energy equipment. Click for more information >>

After years of accumulation,the company has developed into a large-scale,grouped,diversified enterprise. Now we comprises 7 major business centers: Boiler Business Center, Cryogenic Vessel Business Center, Pressure Vessel Business Center, Central Air Conditioning Business Center, Engineering Installation Business Center, International Trade and Internet of Things Business Center. Click for more information >>

The company highly focuses on the green energy pressure equipment industry,the leading products are: LPG Tank, Liquid Ammonia Storage Tank, LNG Tank, LO2, LN2 and LAr Tank, LCO2 storage tanks and other vacuum insulated cryogenic pressure vessels; Oil(Gas)fired boiler,Thermal Oil boiler,Biomass Boiler,Waste Heat boiler etc; Denitration engineering equipment,Thermal energy storage equipment,Complete set of chemical equipment and other pressure vessel products, Ground(Water)Source Heat Pump, Air Source Heat Pump, Water-cooled screw unit,Air cooling module and other central air conditioning HVAC equipment.The planned products include large-scale thermal energy center,LNG transport vehicle,LNG tank container and other high-end green energy equipment. Click for more information >>

After years of accumulation,the company has developed into a large-scale,grouped,diversified enterprise. Now we comprises 7 major business centers: Boiler Business Center, Cryogenic Vessel Business Center, Pressure Vessel Business Center, Central Air Conditioning Business Center, Engineering Installation Business Center, International Trade and Internet of Things Business Center. Click for more information >>

<<<GET QUOTE LEARN MORE>>>

Bohai Road Factory

Pressure vessels production base

Ji’nan Road Factory

Boilers production base

Changjiang Road Factory

Central air conditioners production base

Nanjing Road Factory

Welding training center

Product Quality Control >>>

Raw material testing

Non-destructive testing

Chemical laboratory

Mechanical performance laboratory

Ultrasonic testing

Strain hardening

Factory Filming >>>

We have over 600 advanced production machines, providing a solid foundation for product manufacturing. The manufacturing process involves more than ten steps, including cutting, head pressing, rolling, longitudinal and circumferential seam welding, assembly welding, machining, heat treatment, hydrostatic testing, sandblasting, painting, and more.Each step is staffed with skilled professionals, and further subdivided to enhance efficiency and product quality.

International Certifications

As the national standard drafting unit, our company stands out in Shandong's manufacturing scene, winning the title of Provincial Manufacturing Single Champion Enterprise. Not only are we recognized as a nationally accredited "Little Giant" enterprise specializing in innovation, but our products and services have also obtained international authoritative certifications such as ASME, CE, ISO, and EAC, showcasing our competitiveness and commitment to quality in the global market.

To ensure top-notch quality, we willingly undergo evaluations by trusted third-party agencies like BV, SGS, TUV, and more. This guarantees our customers get the safest, most reliable products and services.

To ensure top-notch quality, we willingly undergo evaluations by trusted third-party agencies like BV, SGS, TUV, and more. This guarantees our customers get the safest, most reliable products and services.

National Standard Drafting Unit

Provincial Manufacturing Single Champion Enterprise

Nationally Specialized and Sophisticated "Little Giant" Firm

ASME

CE

EAC

Customer Group Photos

Our personnel have participated in exhibitions in more than 20 countries, and our customers are spread across over 60 countries and regions.

30+ Global Top 500 enterprises cooperation experience such as Air Liquide, Coca Cola, Sinopec and so on.

<<<GET QUOTE LEARN MORE>>>

FAQ

F: Are you a manufacturer or a trading company?

Q: We are the original manufacturer, producing pressure vessels, industrial boilers and central air conditioners.

F: Can you provide installation and testing services?

We can send field engineer or we have 7*24 hours online service with all drawing, video and audio data provided. We guarantee 100% customers can successfully complete the installation.

F: Can you guarantee the delivery time?

With major material 100% in stock, 100% assembly line operation, 40 years of production experience, we

guarantee 100% project delivered on time.

guarantee 100% project delivered on time.

F: Do your products meet international standards? What kind of certifications do you have?

Q:Our products are in full compliance with international standards and have been certified and certified by many international standards, including ASME,CE,ISO,EAC,BV,PED,SG,GB etc.