Calcium Carbonate Powder Supplier Used Safe and Reliable Calcium Carbonate Powder Grinding Mill

US $58,000.00-85,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Pressure vessel

Type:

Ultra fine grinding mill

Motor Type:

AC Motor

Capacity(t/h):

0.5-45t/h

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Pressure vessel |

| Type | Ultra fine grinding mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 0.5-45t/h |

| Place of Origin | Shanghai, China |

| Brand Name | Clirik |

| Dimension(L*W*H) | Five models |

| Weight | 4263 KG |

| Warranty | 1 Year |

| The Machines classification | Micron Milling Machines |

| Application | Stone Powder Grinding |

| Color | Customer Requirement |

| Output size | 150-2500mesh |

| After-sale service | Offering Technical Support Grinder Mill |

| Input size(mm) | ≤20mm |

| Quality | High Level |

| Product name | HGM Powder Grinding Mill |

| Price | Negotiatable Resonable |

| Online Service Time | Within 24 Hours |

| Applicable Industries | Energy & Mining, Advertising Company |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

Product Overview

Ultrafine powder grinding mill

Ultrafine powder grinding mill is a new type grinding mill developed by Clirik relying on its technical research and development ability and drawing on the advantages of similar products at home and abroad. With rolling, grinding, impact and other comprehensive mechanical crushing properties such as comprehensive mechanical crushing properties.

This series of Ultrafine powder grinding mill have the characteristics of large output, low energy consumption, long service life and easy maintenance. This is a perfect choice for customers who like a high return on investment.

The Ultrafine powder grinding mill can grind non-metallic ore material. Such as calcite, chalk and limestone, dolomite, bentonite, talc, mica, magnesium stone, illite and pyrophyllite, vermiculite, sepiolite,attapulgite, pale spot, barite, alum stone, black lead, fluorite, phosphate, potash, pumice, etc.More than 1000 kinds of moh‘s hardness under level 6 not inflammable, explosive brittle material.

- - Five models: HGM80, HGM90, HGM100, HGM125, and HGM1680L

- - Finished powder fineness: 325 mesh ~3000 mesh, 5-74 micron

- - The capacity (ton/hour): 0.4T/H - 30T/H

PRODUCT SPECIFICATIONS

Product parameter of Dolomite powder grinding mill :

Model | HGM80 | HGM90L | HGM100L-II HGM100P | HGM125L | HGM168L | |||||

Ring Diameter (mm) | 800 | 900 | 1000 | 1250 | 1680 | |||||

Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | |||||

Roller Number (PCS) | 18-21 | 24-29 | 28-36 | 30-40 | 30-44 | |||||

Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 | |||||

Input Size (mm) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 | |||||

Finished Size (um/mesh) | 74-5 (200-2500) | 74-5 (200-2500) | 74-5 (200-2500) | 100-8 (150-2000) | 100-9 (150-1500) | |||||

Capacity (t/h) | 0.5-5.5 | 0.8-6.5 | 1.2-10 1.2-11 | 2.5-20 | 5-45 | |||||

Outlet Size L*W*H (m) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 | |||||

Note:The capacity is based on the domesitlc CaCO3 Powder factory's feedbackNote:The capacity is based on the domesitlc CaCO3 Powder factory's feedback | ||||||||||

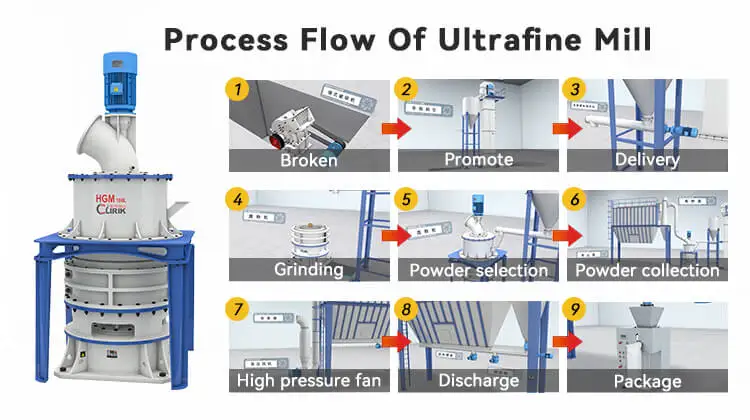

Working Principle

Work Principle of Ultrafine powder mill, ultrafine powder grinding mill, Vertical powder ultrafine grinding mill ,vertical powder mill, powder making machine:

You can learn how the Ultrafine powder grinding mill works by watching the video.

FEATURES AT A GLANCE

Ultrafine powder grinding mill features :

1. Meet client’s requirements for different fineness powder, finished powder fineness is adjustable and at stable quality.

2. Built-in high efficiency classifier, higher classification accuracy, better classification effect.

3. Use new upgraded main machine transmission mechanism, it has higher output, lower energy-consumption, easy maintenance.

4. All main wear parts use quality abrasion-resisting alloy steel, and have a longer working life.

5. The whole system works under negative pressure without dust emission, no coarse particle air pollution, more environment-friendly, higher fineness powder recovery.

6. Smart PLC controlled, remote centralized control, one-button easy operation, intelligent control of feeding material, all the above ensure grinding mill operation stable and high output.

7. The whole grinding mill system with a compact structure could save factory space, with a lower foundation construction cost, it’s a cost-effective investment. High quality calcium carbonate grinding mill for calcium carbonate powder production line

Customer Cases

The following picture is the Ultrafine powder grinding mill site of our previous customers.

If you want more information, you can click here to contact our customer service staff.

If you want more information, you can click here to contact our customer service staff.

Other Products offered

In addition to HGM series Ultrafine powder grinding mill we also have other Ultrafine powder Ultra-fine grinding mill for you to choose.

Why Choose Us

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

What can we do for you?

1.Equipment sizing assistance based on customer’s demand

2.Assistance in planning the layout of workshop according to customer’s site conditions

3.Assistance in designing and installation of the foundation drawing and process flow diagram based on customer’s demand.

4.Guidance on preparation work.

1.Strict control of production to ensure product quality

2.Elimination of hidden dangers with strict factory inspection and traceability system.

3.Providing logistics information.

4.Guidance on the preparation of equipment foundation.

2.Elimination of hidden dangers with strict factory inspection and traceability system.

3.Providing logistics information.

4.Guidance on the preparation of equipment foundation.

5.Guidance for installation and commissioning.

6.Offering professional technical training

C. After-sale:

1.Guidance on various powder production processes for customers.

2.Periodic follow-up on device usage.

3.Instructions on equipment maintenance.

4.Solution of relevant problems in the shortest time.

5.Timely and efficient replacement of spare parts.

6.Professional and fast equipment maintenance.

2.Periodic follow-up on device usage.

3.Instructions on equipment maintenance.

4.Solution of relevant problems in the shortest time.

5.Timely and efficient replacement of spare parts.

6.Professional and fast equipment maintenance.

FAQ

Because there are 5 different kinds of Ultrafine powder grinding mill, so our Ultra-fine grinding mill unit has different prices, I need to ask you for some details for sending you the more suitable quotation:

1. Which kind of material are you going to grind?

(Dolomite; Calcite; Quartz; Basalt; Barite; Limestone; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others )

2. What's the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3. What's the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What's the max input size of the material?

(In inch, centimeter or millimeter)

* If you would like more details, please contact our customer service.

* If you would like more details, please contact our customer service.