China Factory Price 1300 Gallons Propane Gas Tank for Domestic Use

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Shandong, China |

|---|---|

| brand name | HEGUO/CJSE |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | Pressure vessel |

| dimension(l*w*h) | 4676 x 1216 x 1728mm |

| volume (m³) | 5CBM lpg gas tank |

| inner material | Q345R |

| outer material | Q345R |

| Design Pressure (mpa) | 1.77 |

| design standard | GB150/ASME |

| working temperature(℃) | -19 - 50 ℃ |

| warranty | 1 year |

| key selling points | High Productivity |

| Product name | China Factory Price 1300 Gallons Propane Gas Tank For Domestic Use |

| LPG Tank Capacity | 5m3 propane gas tank |

| Filling medium | Liquid Petroleum Gas (propane) |

| Working pressure | 1.63 MPa |

| MAWP | 1.82 MPa |

| Volume available | 5m3 to 200m3 lpg gas tank |

| Key words | lpg tank, lpg gas tank, lpg storage tank |

| Type | Horizontal LPG Storage Tank,LPG Gas Tank |

| Certification | ISO9001 ISO14001 ASME |

| Suitable material | Q345R carbon steel or 16MnDr |

| Condition | New |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Showroom Location | Algeria, Sri Lanka |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Construction works , Civil and industrial gas station |

| Capacity | 5m3 |

| Max Working Pressure(MPa) | 1.82 MPa |

| Weight | 1570 |

Product Detail

China Factory Price 1300 Gallons Propane Gas Tank For Domestic Use

The liquefied petroleum gas storage tank (LPG Tank) is a pressure vessel for storing liquefied petroleum gas, and is mainly used in lpg gas storage stations and chemical enterprises.

LPG storage tanks are special equipment that can only be produced by enterprises approved by the General Administration of Quality Supervision, Inspection and Quarantine. It is necessary to have three types of pressure vessel design and manufacturing qualifications issued by the General Administration of Quality Supervision, Inspection and Quarantine.

Design Parameters of LPG Tank | ||||

Tank Type | III | |||

Capacity of Tank | M3 | 5 | ||

Orientation of LPG Tank | Horizontal Single Layer | |||

Working Pressure | MPa | 1.63 | ||

Design Pressure | MPa | 1.77 | ||

Max.allowance working pressure | MPa | 1.82 | ||

Working Temperature | ℃ | -19~50 | ||

Design Temperature | ℃ | -20/54 | ||

Medium | LPG (Propane) | |||

Density of Medium | kg/m3 | 560 | ||

Main Material | Q345R | |||

Filling Coefficient | 0.9 | |||

Setting Pressure of Safety Valve | MPa | 1.82 | ||

Design Life | 20 Years | |||

Heat Treatment | YesPost-weld heat treatment | |||

Hydrostatic test pressure | MPa | 2.28 | ||

Air tightness test pressure | MPa | 1.77 | ||

Design, Manufacturing and Inspection Standard | GB150/ASME | |||

LPG TANK SPECIFICATIONS | ||||||

Model | Specifications (mm) | Weight in theory (KG) | LPG Tank Length (mm) | |||

WG1.77-1200-5 | DN1200 x 3980 x 8/8 | 1580 | 4676 | |||

WG1.77-1400-5 | DN1400 x 2750 x 10/10 | 1770 | 3545 | |||

WG1.77-1400-10 | DN1400 x 5980 x 10/10 | 2910 | 6789 | |||

WG1.77-1600-10 | DN1600 x 4400 x 10/10 | 2750 | 5303 | |||

WG1.771800-15 | DN1800 x 5250 x 12/12 | 4215 | 6247 | |||

WG1.77-2000-20 | DN2000 x 5650 x 12/12 | 4965 | 6747 | |||

WG1.77-2000-25 | DN2000 x 7250 x 12/12 | 5915 | 8347 | |||

WG1.77-2000-30 | DN2000 x 8850 x 12/12 | 6870 | 9947 | |||

WG1.77-2400-40 | DN2400 x 8000 x 14/14 | 9010 | 9334 | |||

WG1.77-2600-40 | DN2600 x 6600 x 14/16 | 8910 | 8036 | |||

WG1.77-2600-50 | DN2600 x 8500 x 14/14 | 10525 | 9934 | |||

WG1.77-2600-60 | DN2600 x 10360 x14/14 | 12335 | 11796 | |||

WG1.77-3000-80 | DN3000 x 10250 x 16/18 | 16800 | 11888 | |||

WG1.77-3000-100 | DN3000 x 13200 x16/18 | 19970 | 14838 | |||

WG1.77-3200-100 | DN3200×11300×18/18 | 21210 | 13038 | |||

WG1.77-3400-100 | DN3400×9850×20/20(18) | 22620 | 11700 | |||

WG1.77-3600-100 | DN3600×8550×20/22(20) | 22285 | 10492 | |||

WG1.77-3600-120 | DN3600×10500×20/22(20) | 25765 | 12442 | |||

WG1.77-3600-150 | DN3600×13500×20/22(20) | 31140 | 15442 | |||

WG1.77-3800-200 | DN3800×16300×22/22(20) | 41515 | 18342 | |||

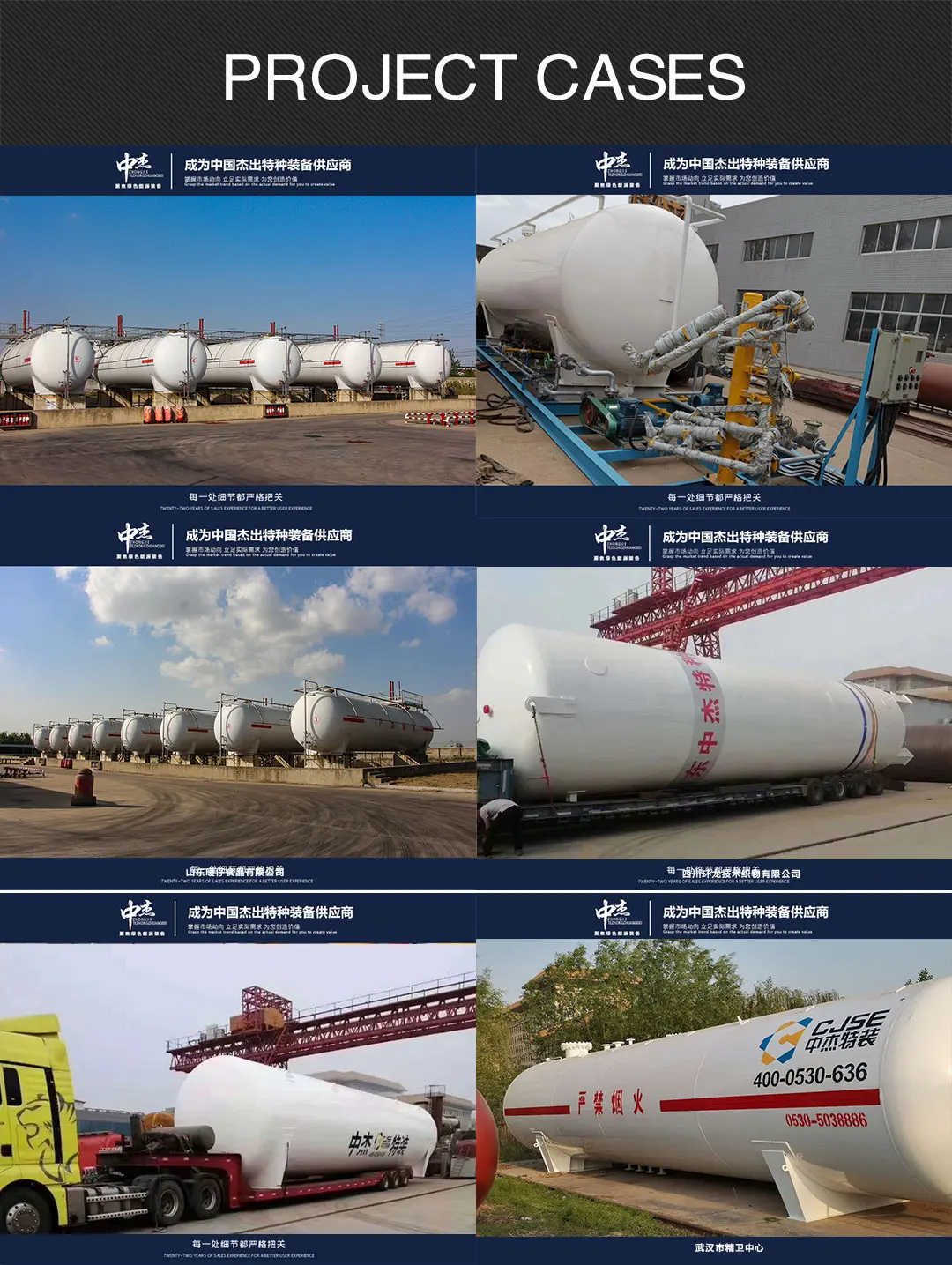

Our advantages for China Factory Price 1300 Gallons Propane Gas Tank For Domestic Use

1) We are the largest lpg tanks production base of China

2) We adopt high quality steel materials for our lpg storage tank

3) We have perfect quality assurance system

4) We have complete welding process

5) We are on the leading manufacturer of pressure vessel with more than 30 years experiences

6) We also have advanced technology and equipment to ensure goods quality

X-Ray Inspection

All main welding seam 100% X-ray detection,

Nozzle, flange C.D welding 100% surface flaw detection to ensure welding quality

Modern Spraying Room

Heat Treatment for China Factory Price 1300 Gallons Propane Gas Tank For Domestic Use

The whole annealing process is adopted to completely remove the internal stress of the tank body, which is of high safety.Different from local annealing with electric heating belt.

Our company has the largest one-time annealing furnace with 300 cubic meters. According to the characteristics of metals, the heating curve is set to completely remove the internal stress of the tank, which greatly improves the safety performance

LPG TANK

Aboveground lpg tank : 5000L to 200,000 L

Underground lpg storage tank: 5000 L to 100,000 L

Design Pressure: 1.77MPa

Max. allowance working pressure: 1.82MPa

LPG Tank type: Horizontal Elliptical head Single Layer Pressure Vessel

Skid Mounted LPG Filling Stations

Capacity: 5m3 10m3 15m3 20m3 25 m3 30m3 and 50m3

Standard configuration:

LPG Tank x 1pc. Valves x 1 set,

Hydrocarbon Pump x 2 pcs,

Universal crane tube hose x 1 pc

Gas alarm x 1 pc, Anti-static x 1pc,

Skid base x 1 pc, ,Electricity x 1set,

lpg dispensesr and filling scales will be equipped according to user' demands.

LNG TANK

Capacity: 5M3 to 150M3

LNG Tank type: Horizontal or Vertical Double Layer Vacuum Insualted Cryogenic Tank

Inner Materials: SS30408 Stainless Steel

Shell Materials: Q345R Carbon Steel

Cryogenic LO2/LN2/LAR/LCO2 TANK

LO2/LN2/LAR Tank

Capacity: 5000L to 50,000 L with 8bar and 16bar pressure

Inner materials: SS30408 Stainless Steel

Shell materials: Q345R Carbon Steel

LCO2 Tank

Capacity: 5000L to 100,000 L with 22bar pressure

Inner Materials: 16MnDR

Shell materials: Q345R

Packing of LPG Tank: Seaworthy Packing;

Loading conditions by sea transportation:

1.one set 5m3 LPG Tank load in one 20GP;

2.one set 10m3 (DN1600) load in one 20GP;

3.one set 15m3 load in one 40HQ;

4.one set 20m3 load in one 40HQ;

5.one set 30m3 load in one 40HQ;

6.40m3,50m3, 60m3 should be load in 40FR;

7.More than 60m3 lpg tank should be load in bulk vessel .also according to customers special request.

Our company has Class A pressure vessel design certification, Class A pressure vessel manufacturing certification, Class B boiler manufacturing certification, GC2/GB2 pressure pipe installation and renovation maintenance certification, boiler level 2 installation and renovation maintenance certification, Class A II refrigeration and air conditioner equipment maintenance and installation certification and so on.

1)WNS/SZS Oil Gas Fired Steam Boiler/Hot Water Boiler;

2)DZH/DZL/SZL Model Biomass Pellet Wood/Coal Fired Steam Boiler / Hot Water Boiler;

3)YY(Q)W Series Natural Gas or Diesel Oil or Heavy Oil Fired Thermal Oil Boiler;

4)YGL/YGW/YLW Type Solid Fuel Wood Pellet Biomass Fired Thermal Oil Heater Boiler;

5)Waste Heat Recovery Boiler;

6) Stationary LPG Storage Tank (5000L to 200,000L)

7) Cryogenic Storage Tank (LNG Tank, Liquid Oxygen/Nitrogen/Argon/LCO2 Tank)

8) Mobile Skid Mounted LPG Filling Station (5000L to 60,000L)

9) Integrated design, manufacturing, and installation services

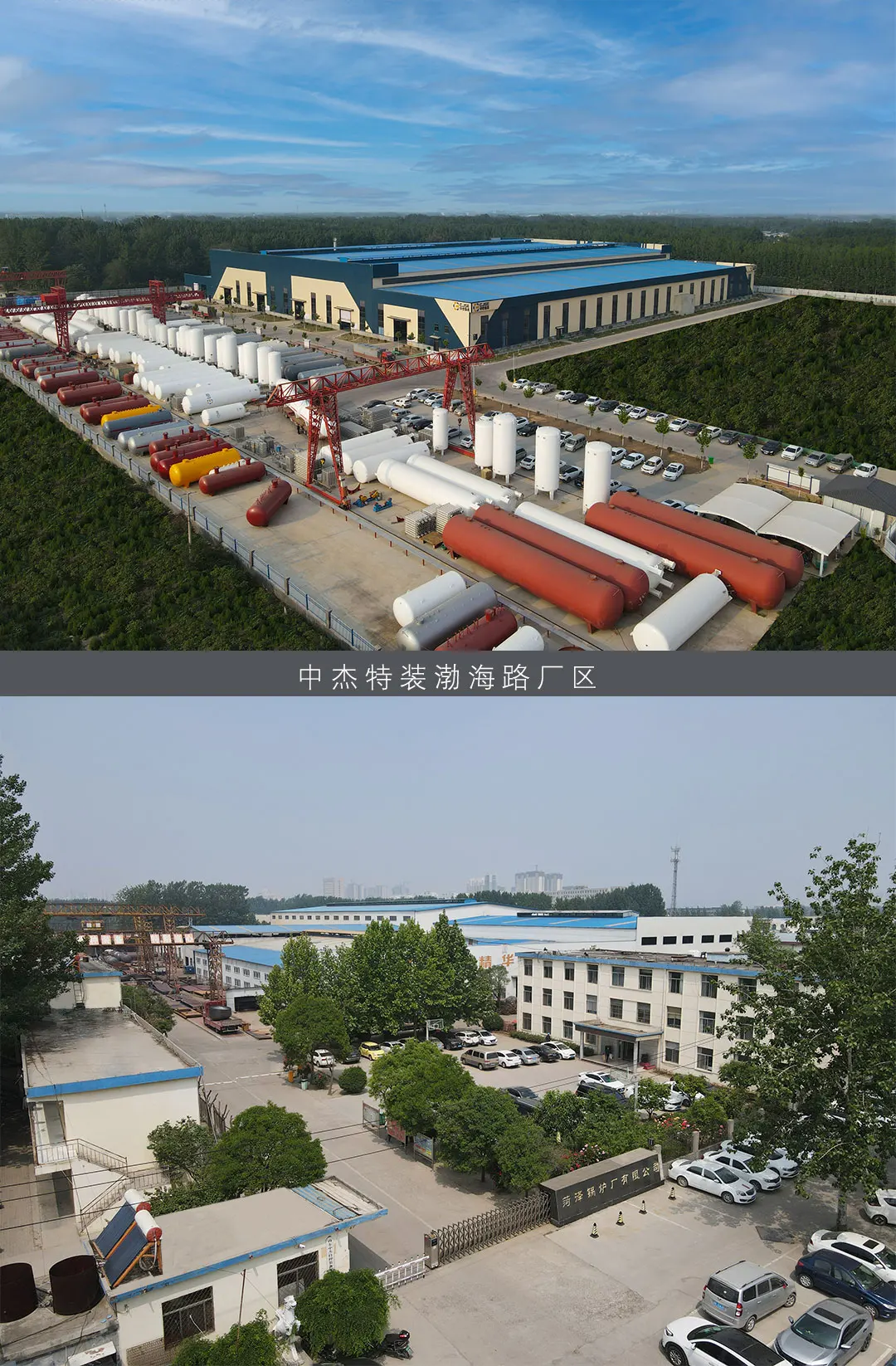

Shandong Zhongjie Pressure Equipment(CJSE) has been specialized in providing our customer with professional equipment, integra solutions and other related installation services for over 30 years, accumulated plenty of experience in boilers, pressure vessels(LNG/LPG/industrial storage tanks) manufacturing, LNG/LPG overall solution developing, station/factory engineering and customized equipment manufacturing. Now our company processes ASME certification and our equipment has been exported to over 30 countries.

1.Q: Are you a factory or trading company?

A: We are a leading manufacturer of pressure vessels,including lpg storage tank, LNG storage tank, cryogenic vacuum insulated storage tank, liquid ammonia tank, skid mounted lpg filling stations,and spare parts with more than 30 years experiences. We are the largest production base of lpg storage tank in China now, sincerely welcome to visit our factory.

2. Q: Could you customize exactly according to my requirements ?

A: Yes. OEM is available. We have professional R&D team, we can produce the product exactly according to your requirements.

3. Q:What service can I get from you?

A: We can offer complete solutions integrated with design, manufacturing, installation, inspection and maintenance at competitive prices. And We provide lifelong tracking service and one year free warranty for all of our products. we also provide training and technical support to guide you install and commission your product.

4.Q: What is the MOQ ?

A: One piece is acceptable, the more the quantity, the more favorable the price.

If you are interested in our any product, please kindly contact us soon