China Gold Mine Mills Wet Pan Grind Mill Price for Gold Grinding

US $3,450.00-3,560.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Gearbox, motor

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

1

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Gearbox, motor |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1 |

| Place of Origin | Henan |

| Brand Name | NESTOR |

| Dimension(L*W*H) | 2300*2300*2000 |

| Weight | 5000 KG |

| Warranty | 1 Year |

| Product name | mine wet pan mill |

| Other name | China wet pan mill for gold |

| Keywords | mill pan gold grind |

| roller size | 1300 mm |

| roller thickness | 170 mm |

| ring size | 1800 1200 mm |

| ring thickness | 100 mm |

| water pan thickness | 4 mm |

| Local Service Location | None |

| Main Products | Jaw crusher, ball mill, concentrator, shredder |

Product Detail

WELCOME TO INQUIRY AND ORDER!!!!

stocks are available within 20 sets!!!!!!!!!

whatsapp&wechat: 15238367461

Products Description

Product introduction

Mainly used with gold, silver, lead, zinc, iron, molybdenum, copper, antimony mine, mine, all ball mill can be selected grind gold machine can be used. Characteristics: grind gold through the raw material mixing, rolling, crushing, rolling repeatedly reach moisture equilibrium ratio of uniform, low gas content, improve the forming rate and forming quality, grind the material through the machine molding Products with high density, good strength, no porosity ratio weight. Energy efficient, high volume of output, the product is used for iron ore process tailings recovery, not to slag the loss of effective resources can be fully utilized

Use and Maintenance

1. The raw materials shouldn’t begin to be put into the machine before the gold selecting wet pan mill running normally.

2. The raw materials are not allowed to be left in the machine. Suppose the machine is stopped while during operation, the

residual materials should be cleared immediately, and then the gold selecting wet pan mill can be started again.

3. The raw materials should be put into the machine uniformly. It's better to use feeding equipments together with gold selecting wet pan mills.

4. The bearing part should be applied with butter regularly.

5. Every bolt should be checked regularly to avoid flexibility.

6. The bearing should be changed in time if it is damaged to avoid ruining other parts.

7. While the machine is running, if there were abnormal noise, or the temperature was too high, or the motor current was too high, or other unappreciated cases, the gold selecting wet pan mill should be stopped immediately.

8. The V-belt should be removed while examining and repairing the machine for your safety.

2. The raw materials are not allowed to be left in the machine. Suppose the machine is stopped while during operation, the

residual materials should be cleared immediately, and then the gold selecting wet pan mill can be started again.

3. The raw materials should be put into the machine uniformly. It's better to use feeding equipments together with gold selecting wet pan mills.

4. The bearing part should be applied with butter regularly.

5. Every bolt should be checked regularly to avoid flexibility.

6. The bearing should be changed in time if it is damaged to avoid ruining other parts.

7. While the machine is running, if there were abnormal noise, or the temperature was too high, or the motor current was too high, or other unappreciated cases, the gold selecting wet pan mill should be stopped immediately.

8. The V-belt should be removed while examining and repairing the machine for your safety.

Working principle

1.When inputting gold sand into the rolling drum, the rollers compress the sand over and over into tiny particles.

2.Please put in 5 kg mercury at first, the mercury can absorb the gold or other metals.

3.At last, use a high-density red cloth to wrap mercury up.

4.Then squeeze it, the mercury will be pressed out and pure gold stayed.

5.As to the large capacity, we can use mercury shaking machine and mercury steamer to replace the manual work.

2.Please put in 5 kg mercury at first, the mercury can absorb the gold or other metals.

3.At last, use a high-density red cloth to wrap mercury up.

4.Then squeeze it, the mercury will be pressed out and pure gold stayed.

5.As to the large capacity, we can use mercury shaking machine and mercury steamer to replace the manual work.

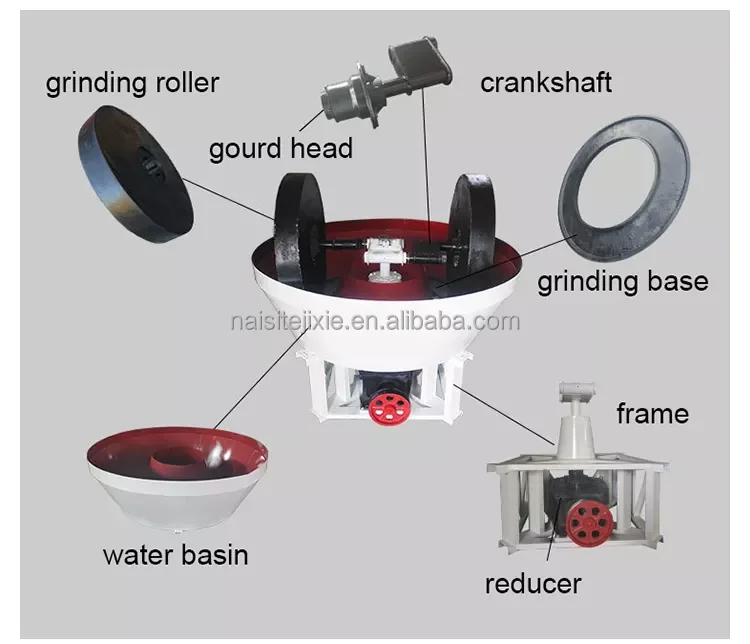

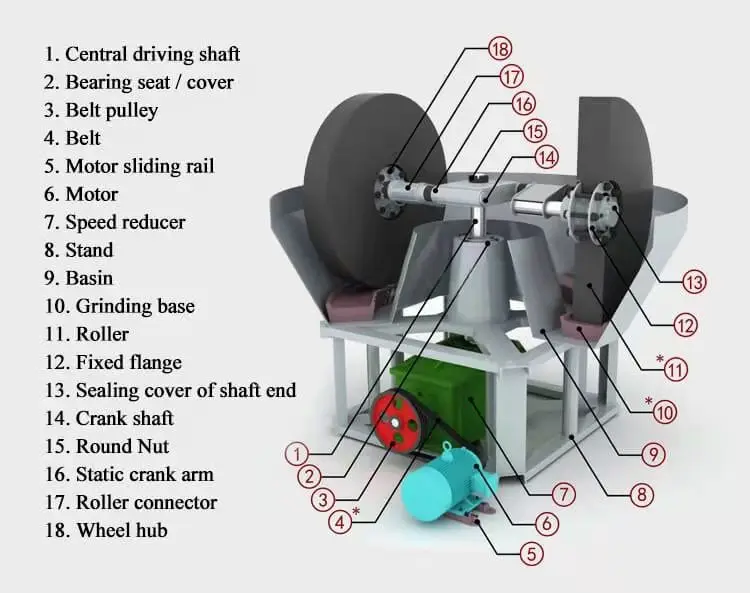

Details Images

water pan thickness: 4 mm

(we can make 6 mm as per your special demands)

ring thickness: 100 mmring size:180/120 mm

under support frame: #16 steel

roller thickness: 170 mm

roller weight:1300 kg

motor: 1100 5.5 KW

1200 7.5 KW

bearing

gearbox: 45

Shaft

roller connector

central driving shaft

belt

fort

wheel hub

roller connector

belt pulley

PRODUCT SPECIFICATIONS

model | specification | motor | production | speed | weight |

1100 | 1100*180*80*250 | 5.5 KW | 500 KG/H | 17-19 r/min | 4500 kg |

1200 | 1200*180*80*250 | 7.5 KW | 1000 KG/H | 17-19 r/min | 5000 kg |

1300 | 1300*250*150*350 | 15 KW | 1500 KG/H | 16-18r/min | 6500 kg |

1400 | 1400*250*150*350 | 18.5 KW | 2000 KG/H | 16-18 r/min | 7500 kg |

1500 | 1500*350*200*460 | 22 KW | 2500 KH/G | 20-22 r/min | 11000 kg |

1600 | 1600*400*200*500 | 30 KW | 3000 KG/H | 20-22 r/min | 12000 kg |

Working Site

Product packaging

Packing:

A 20" GP can load 5 sets of model 1200 or below 1200 size models. We can make different packaging according to different machine with international export standard container, wooden box.We can also pack as customer's requirement.

Delivery Time:

5-10 sets within 3 days

A 20" GP can load 5 sets of model 1200 or below 1200 size models. We can make different packaging according to different machine with international export standard container, wooden box.We can also pack as customer's requirement.

Delivery Time:

5-10 sets within 3 days

10-20 sets within 5 days

20-40 sets within 10 days

Company Profile

Henan NESTOR Machinery CO., LTD

Henan Nestor Machinery Equipment Co , Ltd. ,founded in 1980. It is located in the West Development Zone of Gongyi city with convenient, transportation, well-equipped enterprises, high-quality employees. Our factory is engaged in mineral processing equipment research, design, production for forty years. Our products are exported all over the world.We produce various types of ball mills, crushers, wet mills, magnetic separators, classifiers, flotation machines and other

mineral processing equipment, mainly used for gold, silver, lead, zinc, iron, molybdenum, antimony and other ore selection. We also produce Impact crusher, Hydraulic cone crusher, Heavy hammer crusher, Rotary crusher, Compound crusher, Double shaft shredder, Mobile crushing station, Ball mill, Sand-making and sand-washing equipment, fine sand recycling machine, belt conveyor, vibrating screen, dryer, rotary kiln, cement brick machine, etc. . And we also undertake the complete set of stone sand production lines, mineral processing production lines and mineral separation production line. Our products are qualified by State Mine Machinery Quality Supervision and Inspection Center.

Customer Visit

FAQ

Q1: Are you fatory or trade company?

A1: We are factory in China .

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3.Our senior engineer will supply installation and training service on-line or on-site .

Q4: How about the wear parts supply?

A4: We will supply the wear parts with factory price . You can buy them from our factory in China.

Q5: What about after -sale service?

A5:12 months warranty for all kinds of products.

Q6: How to get the free solution and quotation ?

A6: Please send inquiry to us, leave your whatsapp and email , our sales manager will contact you within 1 hours.

A1: We are factory in China .

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3.Our senior engineer will supply installation and training service on-line or on-site .

Q4: How about the wear parts supply?

A4: We will supply the wear parts with factory price . You can buy them from our factory in China.

Q5: What about after -sale service?

A5:12 months warranty for all kinds of products.

Q6: How to get the free solution and quotation ?

A6: Please send inquiry to us, leave your whatsapp and email , our sales manager will contact you within 1 hours.

Contact Us