China Manufacture Asphalt Plant Asphalt Concrete Mixing Equipment Asphalt Mixing Plant Cases

US $298,000.00-320,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Gearbox, PLC

Place of Origin:

Henan, China

Brand Name:

Sinoma

Voltage:

220v 380v

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Gearbox, PLC |

| Place of Origin | Henan, China |

| Brand Name | Sinoma |

| Voltage | 220v 380v |

| Power | 547 kw |

| Dimension(L*W*H) | - |

| Weight | 300000 kg |

| Warranty | 1 Year |

| UNIQUE SELLING POINT | High operating efficiency |

| Mixer Capacity | 2500 kg |

| Fuel Consumption | 5.5-7 kg/t |

| Dust removal effect | ≤20 mg/Nm³ |

| Aggregate Measurement Accuracy | ±0.5% |

| Powder Measurement Accuracy | ±0.5% |

| Asphalt Measurement Accuracy | ±0.25% |

| Product name | Asphalt Mixing Plant |

| Application | Road Asphalt Concrete |

| Color | Customizable |

| Advantage | High Production Efficiency |

| Applicable Industries | Building Material Shops, Manufacturing Plant |

| Showroom Location | None |

| Warranty of core components | 1 Year |

| Condition | New |

| Marketing Type | New Product 2024 |

Product Detail

Product Description

LB series stationary type asphalt batch mixing plant can produce high-quality asphalt of various proportions.

The product technology is mature, the operation is stable, the specifications and models are complete, the efficiency is high, the output is large, and the quality of the finished asphalt is good. It is suitable for road construction projects of various scales and grades, and its advantages are more obvious in large-scale road construction projects and high-grade highway construction projects.

Product Paramenters

Model | Capacity | Mixer Capacity | Fuel Consumption(kg/t) | Total Power | Dust removal effect | |||||||

Fuel Oil | Fuel Coal | ≤20 mg/Nm³ | ||||||||||

LB500 | 40t/h | 500kg | 5.5-7 | 10 | - | ≤20 mg/Nm³ | ||||||

LB700 | 60t/h | 750kg | 5.5-7 | 10 | 178kw | ≤20 mg/Nm³ | ||||||

LB800 | 64t/h | 800kg | 5.5-7 | 10 | - | ≤20 mg/Nm³ | ||||||

LB1000 | 80t/h | 1000kg | 5.5-7 | 10 | 285kw | ≤20 mg/Nm³ | ||||||

LB1200 | 100t/h | 1200kg | 5.5-7 | 10 | 316kw | ≤20 mg/Nm³ | ||||||

LB1500 | 120t/h | 1500kg | 5.5-7 | 10 | 380kw | ≤20 mg/Nm³ | ||||||

LB2000 | 160t/h | 2000kg | 5.5-7 | 10 | 470kw | ≤20 mg/Nm³ | ||||||

LB2500 | 200t/h | 2500kg | 5.5-7 | 10 | 547kw | ≤20 mg/Nm³ | ||||||

LB3000 | 240t/h | 3000kg | 5.5-7 | 10 | 700kw | ≤20 mg/Nm³ | ||||||

LB4000 | 300t/h | 4000kg | 5.5-7 | 10 | 870kw | ≤20 mg/Nm³ | ||||||

LB5000 | 400t/h | 5000kg | 5.5-7 | 10 | 960kw | ≤20 mg/Nm³ | ||||||

Measurement Accuracy: Aggregate: ±0.5% Powder:±0.5% Asphalt:±0.25% | ||||||||||||

* Note: The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

Related Product

Production Line Cases

Product Feature:

1. Dual-shaft mixer, fast and evenly mixing; 2. Modular design, convenient for transportation and installation, fit for worldwide use; 3. Precise screening, accurate measurement, batch mixing, producing good quality finished asphalt; 4. Optional feed for filler and additives such as dye pigment, fibre and foam and the like; 5. Optimized drying drum structure, thermal insulation layer surface, sufficient heating, and higher heat utilization rate; 6. Three control modes: manual, semi-auto and auto, easy and flexible to operate; 7. Two stage dust collector: gravitational dust collector and bag house dust collector, dust emission less than 20mg/Nm3, environmentally friendly.

1. Dual-shaft mixer, fast and evenly mixing; 2. Modular design, convenient for transportation and installation, fit for worldwide use; 3. Precise screening, accurate measurement, batch mixing, producing good quality finished asphalt; 4. Optional feed for filler and additives such as dye pigment, fibre and foam and the like; 5. Optimized drying drum structure, thermal insulation layer surface, sufficient heating, and higher heat utilization rate; 6. Three control modes: manual, semi-auto and auto, easy and flexible to operate; 7. Two stage dust collector: gravitational dust collector and bag house dust collector, dust emission less than 20mg/Nm3, environmentally friendly.

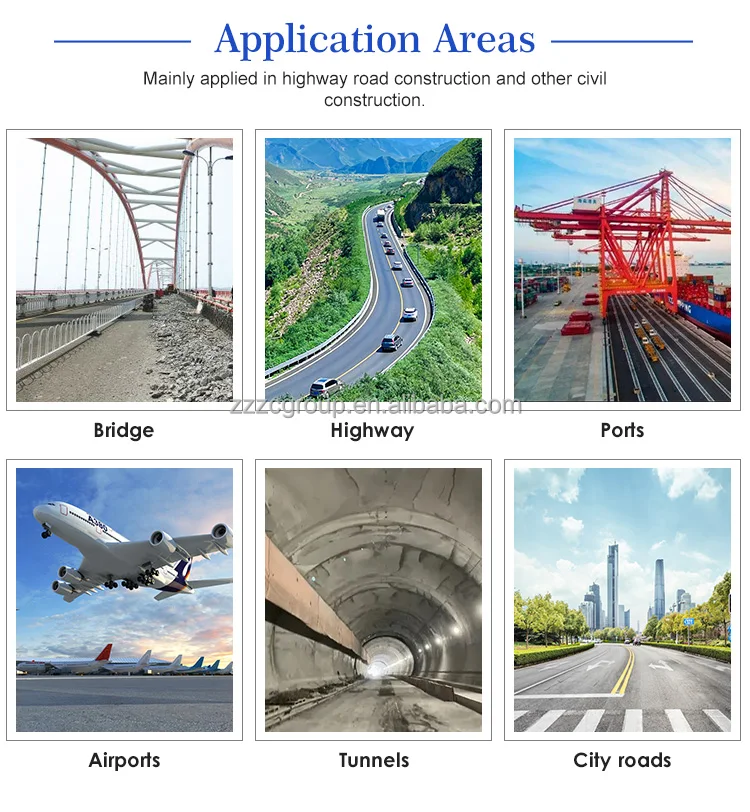

Application Areas&Materials

Application: LB series Asphalt concrete mixing equipment has a wide range of applications, including road construction, bridge engineering, airports, ports, civil construction, etc.

Packing & Delivery

Company Profile

Zhengzhou Sinoma Engineering Technology Co., Ltd. is a large-scale equipment manufacturer that integrates researching & development, production and sales together. We provide cement machinery, concrete machinery, and stone crushing machinery, including: concrete batching plant, asphalt batch mixing plant, complete cement production line, rotary kiln, vertical mill, ball mill, jaw crusher, impact crusher, cone crusher, VSI sand maker, vibrating screen, etc...

Our equipment is widely used in building, mining, construction industry. We are the largest EPC new sand gravel aggregate production line supplier in China. And we use standardized production processes and strict quality control to ensure the quality of all products.

FAQ

1. What is your payment method?

The payment methods can be discussed with our sales manager up to you.

2. How is the product packaged and shipped?

The package is suitable for oversea exporting. We can also choose a special package depending on your needs.

3. How long is the production time?

In stock, can be shipped anytime. And it can also be customized according to your requirements

4. How long is the warranty? Does your company supply the spare parts?

1-3 year. We supply spare parts for you with lowest price.

5. If I need a complete project, can you help us to build it?

Definitely. We can help you to set up a complete production line and give the best professional design. We have already set up over 500 projects in China & Overseas.

6. How about the service?

24 hours online service, various language support, professional technical team to solve all your problems and engineers can be oversea to guide the installation on site.