China Stainless Steel 316 Round Vibration Sifter Machine for Tea Sifting and Grading/Vibrating Screen Shaker

US $2,600.00-3,800.00 / set

1 set(s)Minimum order

place of origin:

henan

product type:

vibrating screen

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

motor, Bearing

brand name:

Yinxing

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | henan |

|---|---|

| product type | vibrating screen |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | motor, Bearing |

| brand name | Yinxing |

| voltage | 220V/380V/415V/480V |

| power(w) | 1.5-5.5 |

| dimension(l*w*h) | 1200*1200*1000 |

| warranty | 1 Year |

| key selling points | High Productivity |

| Product name | Round Vibration Sifter Machine For Tea Sifting And Grading/Vibrating |

| Advantage | Energy conservation |

| Material | SU304 or Q235A |

| Keyword | Tumbler Vibrating Separator |

| Motor | Vibrating machine |

| Layer(s) | 1-5 Layers |

| quality | Passed ISO9001:2008 |

| Function | Screening\separation\sorting\sieving |

| Capacity | 100Kg-10Tons/hour |

| Screen size | 4-0.045mm |

| Type | Separating Plant |

| Condition | New |

| Warranty of core components | 1 Year |

| Showroom Location | None |

| Marketing Type | New product 2024 |

| Weight | 350 |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining, Chemical, food, sand |

Product Detail

Product Details

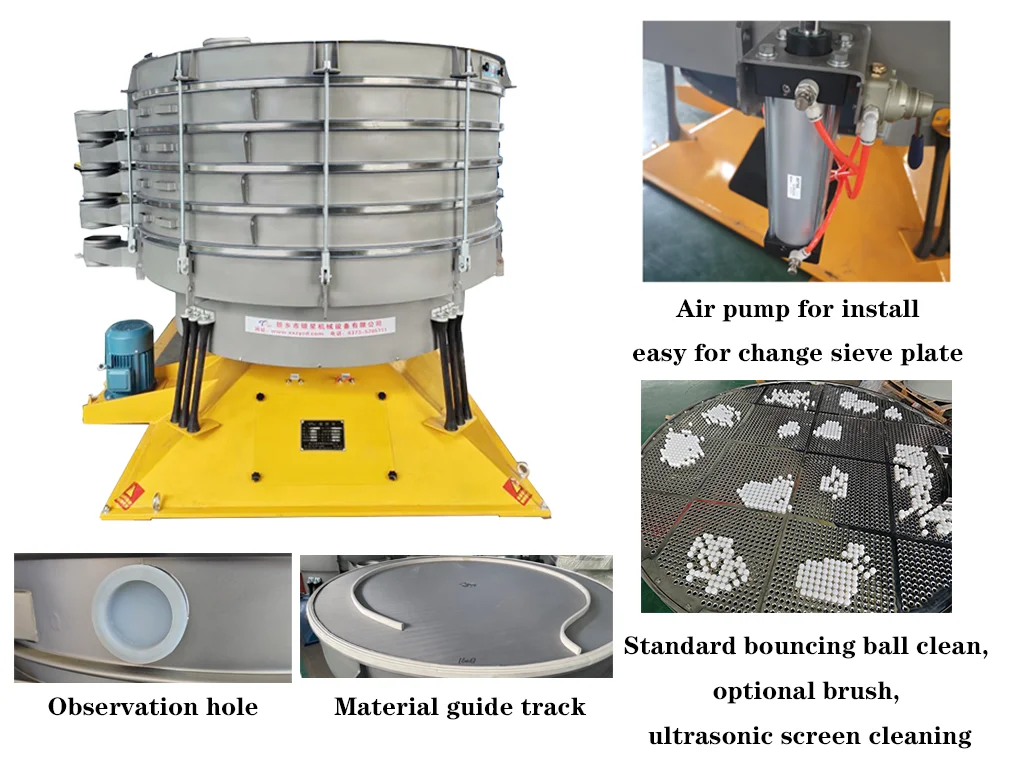

China Stainless Steel 316 Round Vibration Sifter Machine For Tea Sifting And Grading/Vibrating Screen Vibro Sieve Shaker

The movement of a tumbler screening machine is usually compared with simple hand screening similar to the “gold washing pan”.

The product is continuously fed into the centre of the top screen, from where it spreads out evenly to the outside across the

entire screening surface. The finer particles fall through the screen near the centre and the coarser ones successively towards

the periphery. The material is moved in a spiral pattern with increasing acceleration of the particles the further they are from

the centre, with the result that even those particles which are almost the same size as the screen mesh are screened. All the

separated fractions are discharged through the lateral outlets. The screening process is repeated again and again on each deck.

The product is continuously fed into the centre of the top screen, from where it spreads out evenly to the outside across the

entire screening surface. The finer particles fall through the screen near the centre and the coarser ones successively towards

the periphery. The material is moved in a spiral pattern with increasing acceleration of the particles the further they are from

the centre, with the result that even those particles which are almost the same size as the screen mesh are screened. All the

separated fractions are discharged through the lateral outlets. The screening process is repeated again and again on each deck.

Applicable industries

Our products are widely used in the chemical industry, such as fertilizers, activated carbon, plastic particles, calcium carbonate, etc., and can screen 99% of powdered and granular dry materials with low screening noise and high screening efficiency. If you are interested in our machines, please feel free to consult.

Product Paramenters

Model | YX-1000 | YX-1200 | YX-1600 | YX-2000 | YX-2600 | ||||

Effective area(㎡) | 0.67 | 1.13 | 1.83 | 2.63 | 5.3 | ||||

Effective diameter(mm) | 980 | 1180 | 1580 | 1980 | 2580 | ||||

Layers(s) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | ||||

Motor power(kw) | 1.5 or 4 | 2.2 or 4 | 3 or 4 | 4 or 4 | 5.5 or 4 | ||||

Relevant dimensions(mm) 1/2 | 980/900 | 1250/1110 | 1580/1400 | 1880/1800 | 1650/1900 | ||||

Cleaning system | Optional strong silicone, rotating brush, ultrasonic, scraper | ||||||||

Due to space limitations, we only show the standard models. If you want to customize, please contact me.

Work Scene

These are the pictures we took at the customer's site. Our equipment is sold in a very wide area and has received numerous positive reviews.

Packing and shipping

We can use four modes of transportation: car, train, ship and plane. The goods are packed in moisture-resistant multi-layer wooden boxes, rainproof cloth, and direct loading in containers.

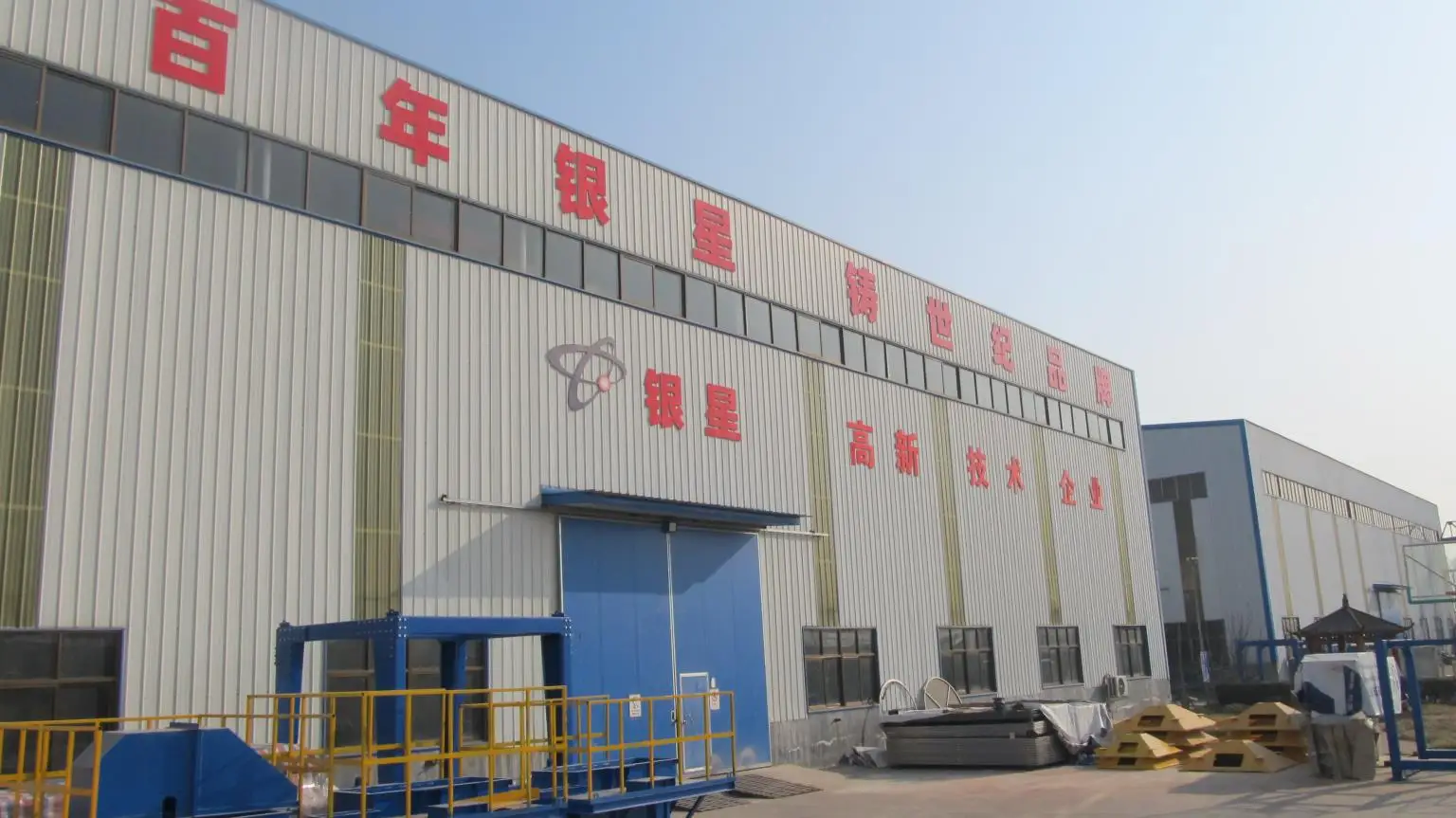

Company Profile

Our company has more than 20 years of experience in the production of screening equipment. It has rich experience in screening chemical industry, food, sugar industry, flour industry, salt industry, mining, metal smelting and other industries. There are more than 100 sets of production and processing equipment in the factory. Choose Yinxing, worry-free screening.

FAQ

Q1: Industry application

Our vibrating screen machines are widely used in food, medicine, chemical industry, metallurgy, mining,

ceramics, plastics, electromagnetic materials, thermoelectricity, building materials and other industries.

Q2: Guaranteed

The whole machine is guaranteed for one year, and the core accessories are guaranteed for three months. After receiving the goods, if you have any quality problems, please contact us in time.

Q3: After-sale service

If there is any installation or test machine problem, provide remote online guidance or on-site service.

Q4: Shipping Method and Shipping Time

1. By air port to port: about 7days depends on port.

Q5: Where is Xinxiang Yinxing Machinery? Is it possible to visit your factory?

Our company is located in Xinxiang City, Henan province, a very famous vibrating screen city in China. The city is near by Zhengzhou Airport, it only take one and half hour from Zhengzhou Airport, welcome to visit our company !

Our vibrating screen machines are widely used in food, medicine, chemical industry, metallurgy, mining,

ceramics, plastics, electromagnetic materials, thermoelectricity, building materials and other industries.

Q2: Guaranteed

The whole machine is guaranteed for one year, and the core accessories are guaranteed for three months. After receiving the goods, if you have any quality problems, please contact us in time.

Q3: After-sale service

If there is any installation or test machine problem, provide remote online guidance or on-site service.

Q4: Shipping Method and Shipping Time

1. By air port to port: about 7days depends on port.

2. By sea port to port: about 20-35 days.

Q5: Where is Xinxiang Yinxing Machinery? Is it possible to visit your factory?

Our company is located in Xinxiang City, Henan province, a very famous vibrating screen city in China. The city is near by Zhengzhou Airport, it only take one and half hour from Zhengzhou Airport, welcome to visit our company !