China Tencan Laboratory 50L 1.5kw Wet&Dry Roll Ball Mill, Micron Powder 304 Stainless Steel Drum Rolling Ball Mill

US $2,000.00-2,200.00 / set

1 set(s)Minimum order

output (kg/h):

0 - 17.5 kg/h

feeding size (mm):

1 - 10 mm

output size (mesh):

200 - 500 mesh

power (kw):

1.5

range of spindle speed(r.p.m):

20 - 50 r.p.m

material:

SUS304

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| output (kg/h) | 0 - 17.5 kg/h |

|---|---|

| feeding size (mm) | 1 - 10 mm |

| output size (mesh) | 200 - 500 mesh |

| power (kw) | 1.5 |

| range of spindle speed(r.p.m) | 20 - 50 r.p.m |

| material | SUS304 |

| application | Chemicals Processing, Food Processing |

| type | Rolling ball mill |

| Product Type | Chemical |

| place of origin | China |

| brand name | Tencan |

| voltage | 220 v |

| dimension(l*w*h) | 1200*600*1000mm |

| weight (kg) | 320 KG |

| warranty | 1 year |

| key selling points | Multifunctional |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | Bearing, Gear, motor, PLC |

| Product name | China Tencan Laboratory 50L 1.5kw Wet&Dry Roll Ball Mill |

| Model | QM-50L |

| Max sample volume | 17.5L |

| Feed size | less than 10mm |

| Output granularity | ≥300 meshes |

| Available Jars | Carbon Steel, Stainless Steel;Nylon , Alumina Ceramic, PU, PTFE Liner |

| Grinding methord | Dry or wet grinding |

| Optional parts | Anti-dust cover , explosion proof system |

| Warranty | 1 Year |

| Condition | New |

| Applicable Industries | Energy & Mining, Other |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

Recommend Products

Products Description

China Tencan Laboratory 50L 1.5kw Wet&Dry Roll Ball Mill, Micron Powder 304 Stainless Steel Drum Rolling Ball Mill

Model No. | Cylinder Volume (L) | Maximum Capacity (L) | Rotate Speed (rpm) | Power Supply (V/Hz) | Power (KW) | Optional Cylinder or Liners | Feed Size (mm) | Output Particle Size (mesh) |

QM-30L | 30 | 10.5 | 20~60 | 220V-50Hz | 0.75 | Carbon Steel Cylinder Stainless SteelCylinder Nylon Liner Corundum Liner Zirconia Liner PU(polyurethane) Liner PTFE Liner | ≤10 | ≥300 |

QM-50L | 50 | 17.5 | 20~50 | 1220V-50Hz | 1.5 | ≤10 | ≥300 | |

QM-100L | 100 | 35 | 20~45 | 380V-50Hz | 2.2 | ≤20 | ≥300 | |

QM-200L | 200 | 70 | 20~40 | 380V-50Hz | 4 | ≤20 | ≥300 | |

QM-300L | 300 | 105 | 20~38 | 380V-50Hz | 5.5 | ≤20 | ≥300 | |

QM-500L | 500 | 175 | 20~36 | 380V-50Hz | 7.5 | ≤20 | ≥300 | |

QM-1000L | 1000 | 350 | 20~34 | 380V-50Hz | 11 | ≤30 | ≥300 | |

QM-2000L | 2000 | 700 | 20-34 | 380V-50Hz | 22 | ≤30 | ≥300 | |

Custom | Custom | Custom | Depends | Depends | Depends | ≤30 | ≥300 |

Light roll ball mill is a kind of equipment used for ultra-fine grinding and mixing for laboratory and small batch production, which is also called rolling machine altar. The machine is preferred equipment for scientific research, teaching, experiment and production due to its advantages such as beautiful design, compact structure, easy operation, high efficiency, and uniform granularity. It is widely applied to industries of electronic material, magnetic material, ceramic glaze, metal powder, nonmetallic minerals, new materials and etc. Optimal design of rotating speed is adopted in the machine, where mill jar is dragged to rotate by rubber roller, balls inside the jar make incline flow movement and disperse materials, thus it obtains best effects of grinding. As result, materials are ground into micron powder. Timing control panel is adopted in the machine with controlling functions of pausing and cumulative timing, and you may set working time according to requirement at any time. It saves time and labor, and is easy for operating.

Working Principle of Roll Ball Mill

When roll mill works, the grinding media and the materials of the cylinder are rotated to a certain height. Due to the gravity,

they fall down from the tube wall. The materials are crushed by impact action of the grinding media, and friction and shearing action of grinding media’s rolling and sliding.

Features of Roll Ball Mill

1. Stable running, high efficiency, low noise and non-pollution

2. All kinds of hard materials can be ground with dry or wet grinding method; the machine is suitable for rough and fine grinding

or can be also applied to mixing materials.

3. The machine is self-equipped with pouring device, and has function of separating powder and ball media automatically,

convenient to output powder.

4. Equipped with safety cover, finest pure degree and non-pollution.

5. Anti-abrasion, high efficiency of grinding.

6. A variety of liner jars in different materials can be selected such as alloyed steel, stainless steel, abrasion-resisting

polyurethane, corundum ceramic, zirconia, and etc. Models of 20-2000L volume are available for customers’ needs.

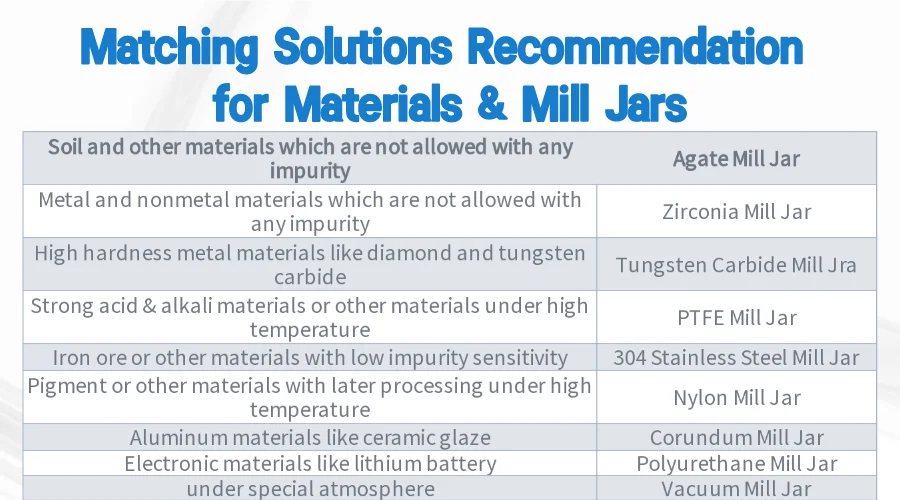

Available & Matched Accessories

Besides the roll ball mill machines, we have all kinds of mill pots for customer’s option, like stainless steel roll mill jar,

zirconia roll mill jar, corundum mill jar, nylon mill jar, PU mill jar, and etc. We further produce all kinds of stainless steel

or carbon steel roll mill jars with corundum liner, zirconia liner, polyurethane liner, PTFE liner and nylon liner in different

sizes from 30L to 2000L.

Additionally, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, carbon steel

mill balls,tungsten carbide mill balls, etc.

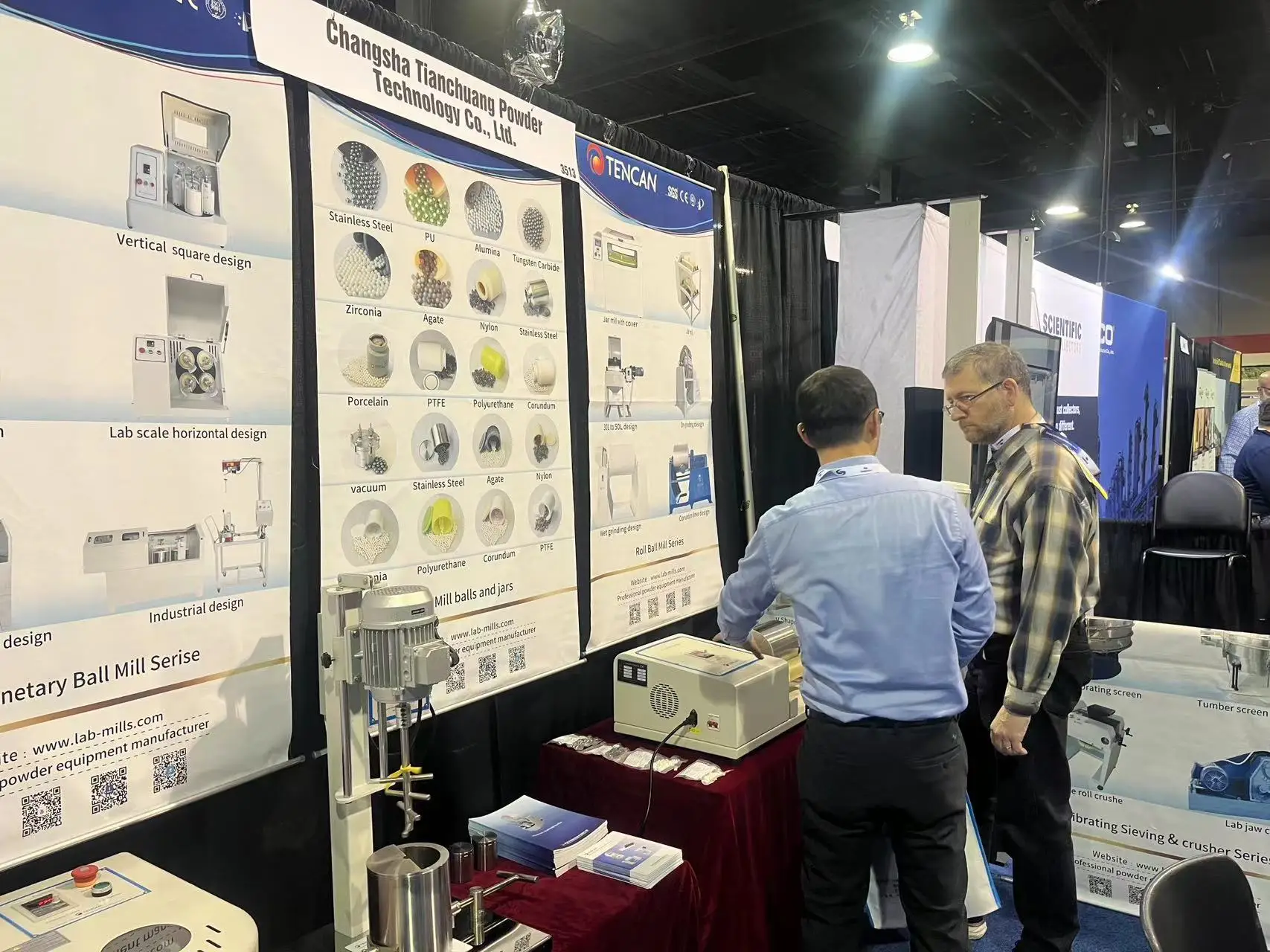

Company Profile

Changsha Tencan Powder Technology Co.,ltd is founded in 2006. It is located in Xingsha Town, Changsha City of Hunan Province, China.

Our factory is a supplier of manufacturing planetary ball mill, roll ball mil, stirring machine, mixer machine, vibration

ball mill, vacuum glove box, mill tank, ball media.. Harvard University, Peking University, Tsingha University, Foxconn, BYD, CASC etc are our regular customers, giving high praise for our machines for their long using life with less mechanical failure.

With the sustained business conception of "credit is the basis, quality is the first", we gain the high trust from customers. A

first-class enterprises goal ----- brand, do first-class enterprises, and take Group operations, to the international development.

Certifications

Communication with Customers

FAQ

1. Are you manufacturer or trade company?

We are one of leading manufacturers in China, which focuses on designing, manufacturing and selling all kinds of powder grinding equipment including planetary ball mills, roll ball mills, stir ball mills, crushers, mixers and sieve shakers as well as accessories matched with machines.

2. What is your delivery time if I place an order?

We often have a great deal of regular machine models and accessories in stock available. If you want to order our regular items, it takes about 1-3 working days to finish packing and inspection, Generally speaking we can make shipment of regular order from our warehouse within 3-7 working days after payment is received.

3. What questions about requirements are required to provide to us if you inquiry about ball mills?

Answers:

* What material is needed to be grind? By wet or dry method?

* How many liters of material are required to be ground per batch?

* What is feed size (mm) of starting materials?

* What final particle size (μm or nm or meshes) is required by grinding?

* Is material allowed with metal impurity contamination while grinding?

4. Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.

Delivery address of material sample:

Changsha Tianchuang Powder Technology Co., Ltd

Room 804, 2nd Building, No.68 Luositang Road, Changsha Economic and Technological Development Zone, Changsha, Hunan, China 410100

Contact Name: Aivin Ai Mobile Phone: +86 13548659522

5. What’s your warranty?

One-year warranty period is provided. If any problem while you are using the machine, you can send Email to: service@lab-mills.com for after-sale services.

6. What is MOQ (Minimum Order Quantity) of one order?

One set of machine or one piece of accessories (like ball mill jar and balls) are acceptable.

We are one of leading manufacturers in China, which focuses on designing, manufacturing and selling all kinds of powder grinding equipment including planetary ball mills, roll ball mills, stir ball mills, crushers, mixers and sieve shakers as well as accessories matched with machines.

2. What is your delivery time if I place an order?

We often have a great deal of regular machine models and accessories in stock available. If you want to order our regular items, it takes about 1-3 working days to finish packing and inspection, Generally speaking we can make shipment of regular order from our warehouse within 3-7 working days after payment is received.

3. What questions about requirements are required to provide to us if you inquiry about ball mills?

Answers:

* What material is needed to be grind? By wet or dry method?

* How many liters of material are required to be ground per batch?

* What is feed size (mm) of starting materials?

* What final particle size (μm or nm or meshes) is required by grinding?

* Is material allowed with metal impurity contamination while grinding?

4. Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.

Delivery address of material sample:

Changsha Tianchuang Powder Technology Co., Ltd

Room 804, 2nd Building, No.68 Luositang Road, Changsha Economic and Technological Development Zone, Changsha, Hunan, China 410100

Contact Name: Aivin Ai Mobile Phone: +86 13548659522

5. What’s your warranty?

One-year warranty period is provided. If any problem while you are using the machine, you can send Email to: service@lab-mills.com for after-sale services.

6. What is MOQ (Minimum Order Quantity) of one order?

One set of machine or one piece of accessories (like ball mill jar and balls) are acceptable.