Clinker Powder Raymond Mill Is Clinker Powder Production Line

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Engine, motor, Pressure vessel

Type:

Raymond Mill

Motor Type:

AC Motor

Capacity(t/h):

1-28

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, motor, Pressure vessel |

| Type | Raymond Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1-28 |

| Place of Origin | Shanghai, China |

| Brand Name | CLIRIK |

| Dimension(L*W*H) | six size |

| Weight | 4600 KG |

| Warranty | 1 Year |

| Color | Customer Requirement |

| Installation | Technical Guidance |

| Feed size | 15-35 |

| Usage | Grinding Mining Stone |

| After sale service | Techniacal Support |

| Price | Negotiable Resonable |

| Output size | 35-425mesh/0.613-0.033mm |

| Factory Visit | Welcomed Warmly |

| Quality | Advanced Technology |

| Grinding material | Limetstone |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

Product Overview

Raymond Roller Mill

Raymond Roller Mill is suitable for grinding of all kinds of materials whose Moh’s hardness is below 9.3, such as calcium

carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, clay,

white mud, mica, refractory material, glass, total about 1000 kinds of materials.

carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, clay,

white mud, mica, refractory material, glass, total about 1000 kinds of materials.

FEATURES AT A GLANCE

Smoothly vibration reduce design

Convenient vane adjust design

The mechin has a strong material applicability ,which suits for many kinds of material whose Moh's hardness is less than 6

Grinding device adopts superimposed seal,sealed performance is good

Raymond Mill

Applied materials

Certification

PRODUCT SPECIFICATIONS

Model | YGM7815 | YGM9517 | YGM1280 | YGM1300 | YGM1620 | YGM1720 | ||

Roller | Quantity(piece) | 3 | 4 | 3 | 4 | 4 | 4 | |

Diameter(mm) | 260 | 310 | 370 | 410 | 450 | 510 | ||

Height(mm) | 150 | 170 | 240 | 280 | 300 | 300 | ||

Inner Diameter (mm) | 780 | 950 | 170 | 1270 | 1500 | 1720 | ||

Height(mm) | 150 | 170 | 240 | 280 | 300 | 300 | ||

Feeding Size(mm) | 15 | 25 | 20 | 20 | 20 | 35 | ||

Finished Size(mm) | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | 0.613-0.033 | ||

Mill System Power(KW) | 35.7 | 72.65 | 145.15 | 202.15 | 322.2 | 450 | ||

Capacity(t/h) | 1.0-3.0 | 2.1-5.6 | 4.5-12.0 | 6.5-16.0 | 8.0-20.0 | 10.5-28.0 | ||

Overall Dimension (mm) | 4300*3500*5100 | 7100*5900*7900 | 9300*5600*8200 | 9100*8200*8400 | 12500*5700*10500 | 11550*9500*10500 | ||

Working Principle

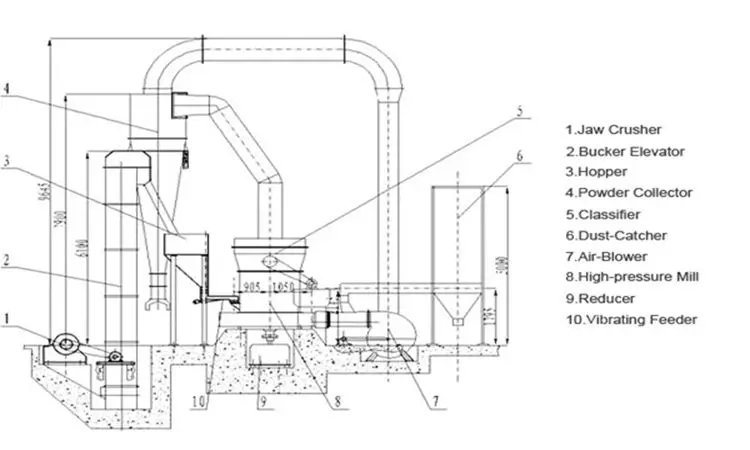

Internal structure and Working Principle of Raymond Roller Mill:

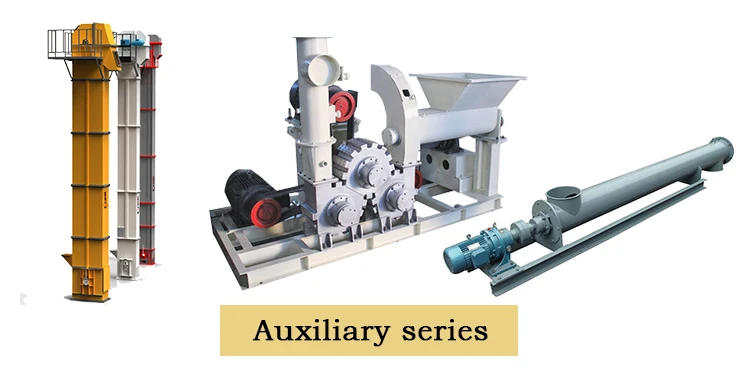

The standard configuration of Raymond Mill consists of main unit, reducer, powder classifier, cyclone powder collector, dust cleaner, blower, control cabinet motor and pipes. The optional accessories include crusher, bucket elevator, feeder.

Big materials are crushed by jaw crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; The airflow is sucked to the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

Big materials are crushed by jaw crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The grinded powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; The airflow is sucked to the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

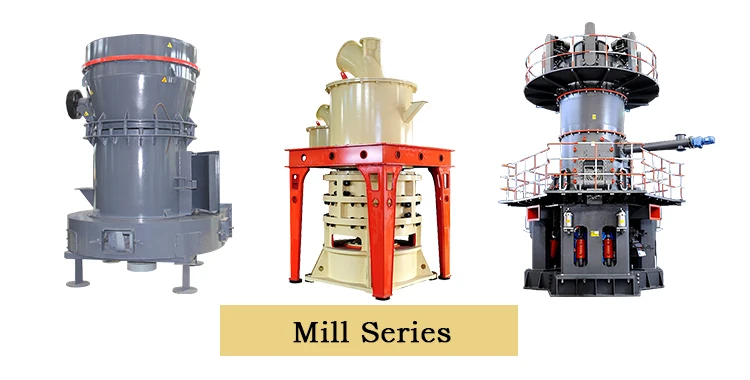

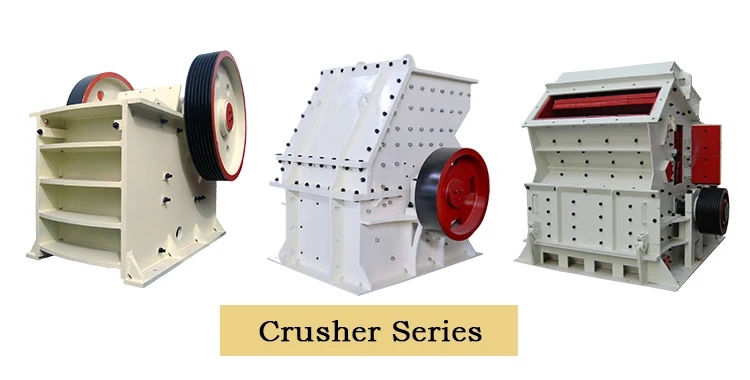

Other Products offered

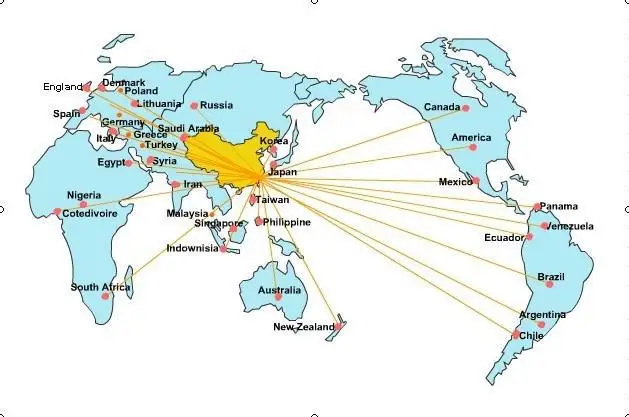

SALES AND SERVICE NETWORK

Company Profile

222

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a professional enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill,Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.

The exhibition

Customer visit

The mode of transportation

What can we do for you?

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

FAQ

Because there 5 different kinds of ultrafine grinding mills, so our HGM series grinding mill unit has different prices, I need to ask you some details for sending you the more suitable quotation:

1.Which kind of material you are going to grinding?

(Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others )

2. What's the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3.What's the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What's the max input size of the material?

(In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging

shipping and discount.

1.Which kind of material you are going to grinding?

(Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others )

2. What's the production capacity you want? How many tons or cubic meters per hour?

( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH < 1 TPH)

3.What's the granularity of the final products you need?

(in milimeter, micron or mesh)

4. What's the max input size of the material?

(In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging

shipping and discount.