Copper Concentrate Production Line for Sale China Copper Ore Production Process Beneficiation Plant Line Supplier

US $63,800.00-75,200.00 / set

1 set(s)Minimum order

Type:

Flotation Separator

Production Capacity:

10-500t/h

Place of Origin:

Henan, China

Brand Name:

ZOOMJO

Voltage:

220/380/440V

Dimension(L*W*H):

Customizable

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Flotation Separator |

|---|---|

| Production Capacity | 10-500t/h |

| Place of Origin | Henan, China |

| Brand Name | ZOOMJO |

| Voltage | 220/380/440V |

| Dimension(L*W*H) | Customizable |

| Weight | 51000 KG |

| Warranty | 2 years |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, motor, Pump, Gear, Pressure vessel, Other |

| Key Selling Points | High Productivity |

| Product Name | Copper Ore Production Process |

| Color | Customers' Requirements |

| Application | Copper Ore Processing Plant |

| After Sale Service | Engineer Overseas Service |

| Price | Competetive (Can Negotiate) |

| Factory | 50,000 Square Meters Closed Workshops |

| Installation and Trial | We Can Send Engineer for Guidance |

| Capacity | 10-500t/h |

| Certification | ISO9001 CE, ISO9001:14000 |

| Main products | Ball Mill, Flotation Machine, Jaw Crusher/Cone Crusher |

Product Detail

Copper Concentrate Production Line for Sale China Copper Ore Production Process Beneficiation Plant Line Supplier

Product Description

Copper ore exists in many forms in nature, and those with good mining value include chalcopyrite, chalcocite, bornite, etc. For its copper selection equipment, we combine the characteristics of copper ore and professionally design and produce a series of ball mills, flotation machines, dryers, jaw crushers, spiral classifiers, mixing barrels, concentrators and other complete sets of copper selection equipment with complete varieties and excellent quality.

Zoomjo Group has more than 20 years of experience in ore beneficiation processing plant. In terms of copper ore processing, it has continuously increased the research and development and innovation of copper flotation reagents, flotation processes, technologies and equipment. According to the characteristics of different types of copper ores and user needs, four major copper flotation process systems have been formed.

1. Copper Ore Priority Flotation Process

2. Copper Ore Mixed Flotation Process

3. Copper Ore Positive Flotation Process

4. Copper Ore Reverse Flotation Process

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Turkey, Afghanistan, Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia,Tanzania, Peru, Mexico, Kazakhstan, Kyrgyzstan, Russia, etc.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Turkey, Afghanistan, Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia,Tanzania, Peru, Mexico, Kazakhstan, Kyrgyzstan, Russia, etc.

Working Flow

Working Principle: According to the floatability of the ore, first float out the single copper concentrate and suppress the rest of the concentrates, then activate and float the other concentrates one by one.

Process Flow: Crushing and screening - Grinding and classification - Prioritizing flotation of copper concentrate - Activated flotation of other concentrates - Concentration and dehydration.

Process Advantages: Strictly implement the reagent system and control the dosage of reagents; easy production operation; high and stable copper concentrate grade.

Working Principle: First, the copper concentrate and other useful minerals in the copper ore are floated out together to obtain a mixed concentrate, and then the mixed concentrate is sorted to obtain a qualified copper concentrate.

Process Flow: Crushing and screening - Grinding and classification - Mixed flotation to obtain mixed concentrate - Concentrate separation and roughing - Concentration and dehydration.

Process Advantages: Save 10% of grinding costs; high working efficiency of flotation machine; 20% lower flotation reagent consumption; wide application range and high production efficiency.

Working Principle: Using anionic collectors, copper ore is floated into the foam product, while gangue minerals remain in the slurry.

Process Flow: Crushing and screening - Grinding and classification - Roughing, concentrating, sweeping - Concentration and dehydration.

Process Advantages: Simple application of flotation reagents; simple operation process; low processing cost; high copper ore enrichment and high recovery rate.

Working Principle: Using collectors, adjust the pH value, float the gangue minerals into the foam product, and the copper ore remains in the slurry.

Process Flow: crushing and screening - grinding and classification - roughing - cleaning - scavenging - concentration and dehydration.

Process Advantages: Saving infrastructure investment; high copper concentrate grade; fast flotation speed; high flotation efficiency.

Main Equipment

cone crusher

ball mill

spiral classifier

flotation machine

efficient thickener

belt conveyor

Technical Parameter

Device name | Specifications | Motor Power (kw) | Number (set) | ||

Jaw crusher | PE-400×600 | 30 | 1 | ||

PEX-250×1000 | 37 | 1 | |||

Vibrating feeder | ZSW-490×110 | 5.5 | 1 | ||

Ball mill | MQ1830×3600 | 135 | 1 | ||

Spiral classifier | FG-1200 | 5.5 | 1 | ||

Mixing barrel | Φ1500 | 3 | 1 | ||

Φ1500 | 3 | 1 | |||

Flotation machine | SF1.2X4 | 88 | 4 group | ||

SF0.62X4 | 24 | 2 group | |||

Belt conveyor | Length according to the site conditions | ||||

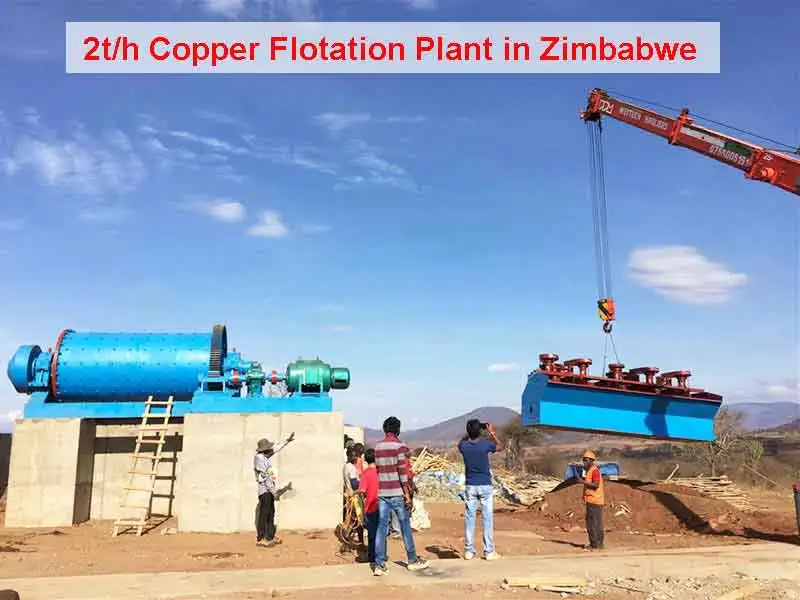

Delivery Site

Packaging Details: We will make different packaging according to different machine sizes. Standard international export packing, container, wooden box.

Delivery Time: We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Customer Cases

Zoomjo flotation process machine are exported to many countries and regions around the world, such as Southeast Asia, South America, Africa, Central Asia, the Middle East, etc. Welcome to visit the factory.

Company Profile

Zoomjo is a large-scale enterprise that mainly produces heavy mining machinery and integrates scientific research, production and sales. It mainly produces various large and medium-sized crushing equipment, sand making equipment, drying and calcining equipment, mineral processing equipment and other series of products.

Zoomjo has developed steadily from its establishment to the present with its technical strength, and has grown stronger day by day, and has gathered a large number of high-level management and scientific research personnel. Our company covers an area of 50,000 square meters, and another 10,000 square meters of modern office space, R&D center and sales center. The company has more than 500 employees, including more than 20 intermediate technicians. With strong technical strength, scientific management system and high product quality, Zoomjo will rapidly grow into an important production and export base of mining machinery.

Contact Us