DZJX 50 100 500 1000 L Cosmetic Mixing Tank Stainless Steel Mixing Tank With Discharge Pump Emulsifying Machine for Cosmetic

US $1,250.00-1,650.00 / set

1 set(s)Minimum order

mixer type:

Homogenizer

barrel volume (l):

50-10000

material processed:

Chemicals, Food

range of spindle speed(r.p.m):

0 - 8000 r.p.m

weight (kg):

100 KG

material:

SUS304, SUS304L, SUS316, SUS316L

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| mixer type | Homogenizer |

|---|---|

| barrel volume (l) | 50-10000 |

| material processed | Chemicals, Food |

| range of spindle speed(r.p.m) | 0 - 8000 r.p.m |

| weight (kg) | 100 KG |

| material | SUS304, SUS304L, SUS316, SUS316L |

| additional capabilities | homogenizer |

| place of origin | China |

| brand name | DZJX |

| voltage | Customized |

| dimension(l*w*h) | Customized |

| Power (kW) | 0.75 kW |

| warranty | 1 Year |

| key selling points | Automatic |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor |

| Condition | New |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Energy & Mining, Other |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Max. Loading Volume (L) | 8000 L |

| Max. Loading Capacity | 8000 |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

Products Description

DZJX 2023 Hot Sale Vacuum Emulsifier Mixer Homogenizer 50 Kg 100 Litre Paste Mixing Tank

* 1. Stainless steel emulsifier mixing tanks are widely used in industries such as coatings, pharmaceuticals, building materials, chemicals,pigments, resins, food, medicine and scientific research.

* 2. Stainless steel stirring tanks have functions such as heating, cooling, insulation, stirring, emulsify and metering.

* 3. According to production and process requirements, heating, cooling, low-speed and high-speed mixing systems, sealing pressure systems, vacuum systems, and metering systems can be designed.

* 4. According to different mixing materials and required mixing effects, the structure of the stainless steel mixing tank can be adjusted and designed with stirring paddles, such as vortex wheel type, paddle type, anchor type, frame type, spiral type, magnetic stirring furnace, etc.

* 5. The heating forms include jacket electric heating and coil heating. The equipment has a reasonable structural design, advanced technology, durability, and features simple operation

and convenient use.

* 6. The pot body is made of 304/316 stainless steel material, and the tank body and pipeline are mirror polished, in line with GMP requirements

* 7. According to the process requirements, the tank can be heated and cooled materials, heating methods are mainly steam and electric heating two; Convenient discharging, can be directly discharging, can also be configured with conveying pump discharging.

Product Structure

1.Heating temperature and homogenizer working time can be set .

2.Frequency speed of top mixing and bottom homogenizer mixer

3.Mixing type: frame scarper mixer and high shear homogneizer .

4.Working capacity can be customized according to clients' requirements .

2.Frequency speed of top mixing and bottom homogenizer mixer

3.Mixing type: frame scarper mixer and high shear homogneizer .

4.Working capacity can be customized according to clients' requirements .

5.Vacuum emuslfiying mixer can be customized according to different requirements of clients.

Application

liquid mixing machine

1.Tank or Vessel: The main body of the mixing tank is a container or vessel that holds the substances to be mixed. It is usually made of stainless steel, carbon steel, or other materials suitable for the specific application. The tank is designed to withstand the pressure, temperature, and other conditions required for the mixing process.

2.Agitator or Mixer: The agitator or mixer is a mechanical device used to blend the substances within the tank. It can consist of various types of impellers, paddles, or blades that create fluid movement within the tank. The agitator is typically powered by an electric motor or another energy source and is responsible for generating turbulence and promoting efficient mixing.

3.Inlet and Outlet Connections: The mixing tank has inlet and outlet connections that allow for the loading of substances into the tank and the discharge of the mixed product. These connections can include valves, pipes, pumps, or other equipment depending on the specific requirements of the mixing process.

4.Instrumentation and Controls: Mixing tanks may be equipped with various instrumentation and control systems to monitor and regulate the mixing process. This can include temperature sensors, pressure gauges, level indicators, pH meters, flow meters, and other instruments. Control systems may be manual or automated and can help adjust parameters such as mixing speed, temperature,

and other variables to achieve the desired mixing results.

5.Heating or Cooling Systems: Some mixing tanks may include built-in heating or cooling systems to control the temperature of the mixture during the mixing process. These systems can use steam, hot water, or other heating mediums, as well as chillers or refrigeration units for cooling.

6.Safety Features: Mixing tanks are often equipped with safety features to ensure the protection of operators and the integrity of the process. These features can include pressure relief valves, emergency stop buttons, safety interlocks, and other mechanisms to prevent over-pressurization, excessive temperatures, or other hazardous conditions.

7.Cleaning Systems: Mixing tanks require regular cleaning to remove any residual material or buildup. They may include features such as spray balls, CIP (Clean-in-Place) systems, or other cleaning mechanisms to facilitate thorough and efficient cleaning operations.

2.Agitator or Mixer: The agitator or mixer is a mechanical device used to blend the substances within the tank. It can consist of various types of impellers, paddles, or blades that create fluid movement within the tank. The agitator is typically powered by an electric motor or another energy source and is responsible for generating turbulence and promoting efficient mixing.

3.Inlet and Outlet Connections: The mixing tank has inlet and outlet connections that allow for the loading of substances into the tank and the discharge of the mixed product. These connections can include valves, pipes, pumps, or other equipment depending on the specific requirements of the mixing process.

4.Instrumentation and Controls: Mixing tanks may be equipped with various instrumentation and control systems to monitor and regulate the mixing process. This can include temperature sensors, pressure gauges, level indicators, pH meters, flow meters, and other instruments. Control systems may be manual or automated and can help adjust parameters such as mixing speed, temperature,

and other variables to achieve the desired mixing results.

5.Heating or Cooling Systems: Some mixing tanks may include built-in heating or cooling systems to control the temperature of the mixture during the mixing process. These systems can use steam, hot water, or other heating mediums, as well as chillers or refrigeration units for cooling.

6.Safety Features: Mixing tanks are often equipped with safety features to ensure the protection of operators and the integrity of the process. These features can include pressure relief valves, emergency stop buttons, safety interlocks, and other mechanisms to prevent over-pressurization, excessive temperatures, or other hazardous conditions.

7.Cleaning Systems: Mixing tanks require regular cleaning to remove any residual material or buildup. They may include features such as spray balls, CIP (Clean-in-Place) systems, or other cleaning mechanisms to facilitate thorough and efficient cleaning operations.

Why choose us

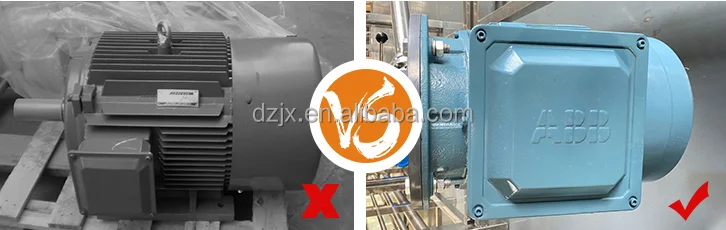

* SIEMENS/ABB Motor

New and original ABB and SIEMENS motor, long service, voltage and electric current can be customized from 220v to 600v, protection grade IP55.

* Mechanical seal technology

Graphite with alloy wear resistance, High-temperature resistance, longer service life.

222

* High quality pharmaceutical grade stainless steel

High quality stainless steel hybrid blade, using the most advanced laser welding technology, beautiful weld, easy to clean.

Products Show

Technical Parameter

Working | Mixing | Homogenizing | Heating way | |||||||||

capacity | Power | Speed | Power | Speed | Suggestion | |||||||

DZF-100L | 100L | 0.55KW | 0-0.63 RPM | 1.5KW | 0-2880 RPM | Electric heating | ||||||

DZF-200L | 200L | 1.5KW | 2.2KW | Electric heating | ||||||||

DZF-300L | 300L | 1.5KW | 3KW | Electric heating | ||||||||

DZF-500L | 500L | 2.2KW | 4KW | Electricor/steam heating | ||||||||

DZF-1000L | 1000L | 4KW | 7.5KW | Electricor/steam heating | ||||||||

DZF-2000L | 2000L | 5.5KW | 11KW | Electricor/steam heating | ||||||||

DZF-3000L | 3000L | 7.5KW | 15KW | Electricor/steam heating | ||||||||

Company Profile

* Xinxiang Dongzhen machinery manufacturing Co., LTD

1.With 36 years of professional production of rubber, food, medicine, chemical and mineral equipment experience, and has a good cooperative relationship with the world 500.

2.All raw materials purchased with domestic and foreign well-known manufacturers.

3.We have designed production lines for many companies, such as cosmetics production line ,clove production line, blue bubble production line, flour production line, yeast production line, detergent production line,etc.

3.We have designed production lines for many companies, such as cosmetics production line ,clove production line, blue bubble production line, flour production line, yeast production line, detergent production line,etc.

4.1 Years Warranty, 14 Days Delivery, Factory Price.

5.14800㎡ factory, Own R&D Team.

6.Free design service, free professional solutions.

7.Passed ISO9001, CE, SGS, Intetek certificates.

Feedback