Electric 100L 200L Stainless Steel Distiller New Copper Multi Spirit Distilling Equipment for Home Alcohol Processing

1 set(s)Minimum order

processing:

Artisanal Quality Custom-Designed Turnkey Solution

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Gearbox, motor, Pressure vessel, Gear, Pump

place of origin:

Jiangxi, China

brand name:

TWO

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Artisanal Quality Custom-Designed Turnkey Solution |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Gearbox, motor, Pressure vessel, Gear, Pump |

| place of origin | Jiangxi, China |

| brand name | TWO |

| model number | TWPD-200 |

| voltage | 110V / 220V / 380V / 400V / 480V / 600V |

| power(w) | 0.75-30KW,Customized |

| weight | 300 |

| processing types | Vodka Brandy Rum Gin Whiskey |

| warranty | 1 Year |

| Usage | Whiskey, Brandy, Gin, Rum, Vodka, Tequila, Moonshine, Alcohol, Spirit |

| Material | SUS304 Stainless Steel / SUS316 Stainless Steel / TP2 Red Copper |

| Name | Home Electric Heated Distiller |

| Capacity | 100-300L |

| Type | Micro Alcohol Distillery Equipment |

| Heating method | Electrical Heating Steam Hearting |

| Package | Wooden Case |

| Size | Customerr's Request |

| Condition | New |

Product Detail

Material | SUS304 Stainless Steel / SUS316 Stainless Steel / TP2 Red Copper | |||||

Application | Whiskey, Brandy, Gin, Rum, Vodka, Tequila, Moonshine, Baijiu, Alcohol, Spirit, Liquor | |||||

Certificate | CE / UKCA / ISO9001 | |||||

Heating | Electric / Steam / Gas / Fuel oil / Heat transfer oil | |||||

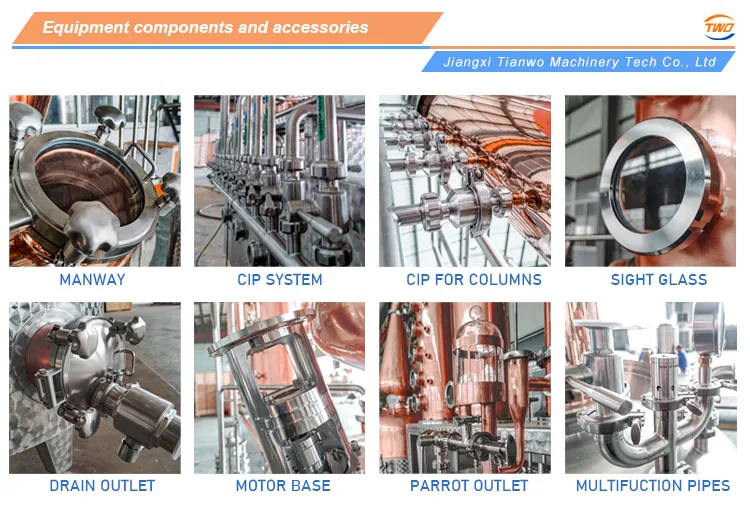

Parts | Still pot, Column, Gin basket, Condenser, CIP, Pipe system | |||||

Voltage | 110V / 208V / 220V / 230V / 240V / 380V / 400V / 415V / 460V / 480V / 600V | |||||

3 phase 50Hz / 60Hz | ||||||

Options | High Torque Mash Agitator | |||||

Copper pot / Stainless steel pot | ||||||

Bottom with spirit collection tank for head heart and tail. | ||||||

Copper dephlegmator / condenser | ||||||

CIP pump and CIP pipe | ||||||

Bottom with spirit collection tank for head heart and tail | ||||||

Warranty | Engineers available to service machinery overseas | |||||

Capacity | 50L / 100L / 200L / 500L / 1000L / 2000L / 5000L /10000L / 20000L | |||||

Our stills, made of copper and stainless steel, are designed to produce high - quality spirits. They're perfect for starting a craft distillery, whether you're making vodka, gin, whiskey, or other spirits.

With Tianwo Machinery's distillation equipment, you can build your distillery with confidence. We offer custom still helmet shapes based on your preferences or distilling needs to bring out the best flavors.

Our hybrid designs integrate various components and come in different sizes and styles. We also provide Grain Handling Equipment, Steam Boilers, and Cooling Systems to meet all your distillery setup needs.

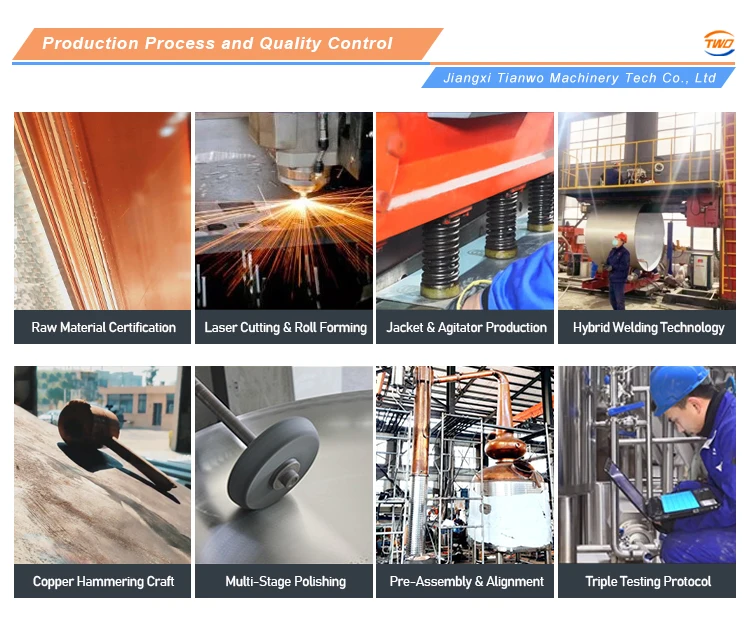

Our equipment uses TP2 copper for thermal conductivity and sulfide removal, enhancing flavor, and SUS304 stainless steel for

durability. Unlike thin copper stills that dent easily, our robust design ensures long-lasting performance and premium taste.

durability. Unlike thin copper stills that dent easily, our robust design ensures long-lasting performance and premium taste.

Artisanal Craftsmanship for Unrivaled Quality

Our distilling equipments are 100% handcrafted by master artisans. Using only the finest stainless steel and red copper, we ensure you receive the most dependable distilling system tailored for your distillery.

Custom - Designed for Distillery Success

Designed with distiller's business in focus, our stills are user - friendly and intuitive. We offer customized configurations to fit any building layout or distillery requirement, eschewing one - size - fits - all solutions.

Comprehensive Turnkey Solution Support

From project management to after - sales service, our team of experts in sales, technical support, and training is here to provide you with professional assistance at every stage of your brewing system setup.

Jiangxi Tianwo Machinery Technology Co., Ltd

Tianwo Machinery is a CE & ISO 9001 certified manufacturer specializing in precision distillation and brewing systems for craft spirits, biopharmaceuticals, and sanitary industries. Located in the Jiangxi Hi-Tech Zone, our 12,000㎡ factory is equipped with CNC machining centers and automated welding lines, ensuring top-tier quality and efficiency.

Tianwo design equipment for craft spirits (Whisky, Gin, Vodka, Rum), brewing systems (beer, saké), and pharmaceutical extraction (herbal medicine, essential oils). With 50+ engineers dedicated to R&D, we offer customized solutions in capacity, automation, and materials, backed by 72-hour 3D design feedback.

Tianwo's 3-step quality assurance includes XRF-tested materials, argon arc welding, and 48-hour pressure testing. We provide 12-month warranty, 24/7 multilingual support, and global shipping to 50+ countries.

Tianwo design equipment for craft spirits (Whisky, Gin, Vodka, Rum), brewing systems (beer, saké), and pharmaceutical extraction (herbal medicine, essential oils). With 50+ engineers dedicated to R&D, we offer customized solutions in capacity, automation, and materials, backed by 72-hour 3D design feedback.

Tianwo's 3-step quality assurance includes XRF-tested materials, argon arc welding, and 48-hour pressure testing. We provide 12-month warranty, 24/7 multilingual support, and global shipping to 50+ countries.

Customization

We customize logos, scale markings, polishing, and accessories for your distillation equipment needs.

Design

We create distillation equipment for both standard and personalized setups.

Innovation

We turn your brewing and distilling ideas into products with prototype and mass - production services.

- Layout Service

Share your building details. We'll offer equipment footprint for perfect space fit.

Share your building details. We'll offer equipment footprint for perfect space fit.

- Technical Drawings

Based on production line layout, we provide clear Technical Drawings for each equipment.

Based on production line layout, we provide clear Technical Drawings for each equipment.

- 3D Sketches

Our 3D valid sketches help you visualize the setup before investment.

Our 3D valid sketches help you visualize the setup before investment.

- All-round Planning

We assist with budgets, electrical work, and building matters for a solid business start.

We assist with budgets, electrical work, and building matters for a solid business start.

- Custom Build & Source

We understand your needs, custom - build and source equipment/components for your distillery.

We understand your needs, custom - build and source equipment/components for your distillery.

- Installation & Commissioning

Tianwo arranges transport, aids installation, and starts up equipment with you, ensuring you know how to operate it.

Tianwo arranges transport, aids installation, and starts up equipment with you, ensuring you know how to operate it.

- Warranty Coverage

1-year warranty on electrical elements and tank bodies. Free replacement or repair for non-artificial electrical issues.

1-year warranty on electrical elements and tank bodies. Free replacement or repair for non-artificial electrical issues.

- Lifetime Support

We offer continuous tech support for as long as you own our equipment to keep your distillery running well.

We offer continuous tech support for as long as you own our equipment to keep your distillery running well.

F A Q

Q1: Are you a manufacturer or trader?

A: We are a certified manufacturer with a 10,000㎡ factory in Jiangxi, China, equipped with advanced machinery (e.g., automated welders, CNC machines) and in-house R&D capabilities. All equipment is designed and produced internally to ensure quality control.

Q2: What types of distillation equipment do you specialize in?

A: Our core products focus on craft spirits and industrial solutions:

* Craft Distillation: Whisky, Brandy, Vodka, Gin, and Rum systems (20L-10,000L capacity).

* Industrial Applications: Pharmaceutical extraction, essential oil purification, and alcohol recycling systems.

* Key Components: Copper/stainless steel columns, CIP cleaning systems, and temperature-controlled fermentation tanks.

Q3: How do you ensure equipment quality?

A: We implement a 3-Step Quality Assurance Process:

1. Material Certification: 304 stainless steel and food-grade copper verified by XRF testing.

2. Precision Manufacturing: Automated welding with X-ray inspection and pressure testing at 1.5x capacity.

3. Final Validation: 48-hour continuous operation test before shipment. Certifications: CE, ISO9001, and SGS available upon request.

Q4: Can you customize equipment specifications?

A: Yes! We offer tailored solutions based on your needs:

* Adjustable capacity (e.g., 50L-200L modular designs).

* Material upgrades (e.g., thicker copper columns for enhanced flavor extraction).

* Automation options (PLC control systems, IoT monitoring).

Q5: What after-sales support do you provide?

A: We guarantee lifetime technical support:

* 12-month warranty covering parts and labor.

* Remote troubleshooting via video call within 4 hours.

* On-site installation available in 30+ countries.

Q6: How about shipping and delivery?

A: We ensure safe and fast global logistics:

* Standard delivery: 25-35 days by sea (FOB Shanghai/Ningbo).

* Packaging: Reinforced wooden crates with waterproof coating.

* Documents: Full export compliance (commercial invoice, CO, etc.).

Q7: What payment terms do you accept?

A: Flexible and secure options:

* 30% deposit + 70% before shipment (T/T, L/C).

* Alibaba Trade Assurance for order protection.

* Crypto payments accepted for repeat clients.

A: We are a certified manufacturer with a 10,000㎡ factory in Jiangxi, China, equipped with advanced machinery (e.g., automated welders, CNC machines) and in-house R&D capabilities. All equipment is designed and produced internally to ensure quality control.

Q2: What types of distillation equipment do you specialize in?

A: Our core products focus on craft spirits and industrial solutions:

* Craft Distillation: Whisky, Brandy, Vodka, Gin, and Rum systems (20L-10,000L capacity).

* Industrial Applications: Pharmaceutical extraction, essential oil purification, and alcohol recycling systems.

* Key Components: Copper/stainless steel columns, CIP cleaning systems, and temperature-controlled fermentation tanks.

Q3: How do you ensure equipment quality?

A: We implement a 3-Step Quality Assurance Process:

1. Material Certification: 304 stainless steel and food-grade copper verified by XRF testing.

2. Precision Manufacturing: Automated welding with X-ray inspection and pressure testing at 1.5x capacity.

3. Final Validation: 48-hour continuous operation test before shipment. Certifications: CE, ISO9001, and SGS available upon request.

Q4: Can you customize equipment specifications?

A: Yes! We offer tailored solutions based on your needs:

* Adjustable capacity (e.g., 50L-200L modular designs).

* Material upgrades (e.g., thicker copper columns for enhanced flavor extraction).

* Automation options (PLC control systems, IoT monitoring).

Q5: What after-sales support do you provide?

A: We guarantee lifetime technical support:

* 12-month warranty covering parts and labor.

* Remote troubleshooting via video call within 4 hours.

* On-site installation available in 30+ countries.

Q6: How about shipping and delivery?

A: We ensure safe and fast global logistics:

* Standard delivery: 25-35 days by sea (FOB Shanghai/Ningbo).

* Packaging: Reinforced wooden crates with waterproof coating.

* Documents: Full export compliance (commercial invoice, CO, etc.).

Q7: What payment terms do you accept?

A: Flexible and secure options:

* 30% deposit + 70% before shipment (T/T, L/C).

* Alibaba Trade Assurance for order protection.

* Crypto payments accepted for repeat clients.