FETECH Spiral Sand Washer XSL-750 Easy to Operation Customized Mineral Washing Machine Application Hydropower

US $7,000.00-8,000.00 / set

1 set(s)Minimum order

Type:

Sprial Separator

Production Capacity:

Customized

Place of Origin:

Jiangxi, China, Jiangxi,China

Brand Name:

FETECH, FETECH

Voltage:

380V

Dimension(L*W*H):

Customized

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Sprial Separator |

|---|---|

| Production Capacity | Customized |

| Place of Origin | Jiangxi, China, Jiangxi,China |

| Brand Name | FETECH, FETECH |

| Voltage | 380V |

| Dimension(L*W*H) | Customized |

| Weight | 1000 KG |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | motor, Bearing, Engine, Motor, Bearing,Engine |

| Key Selling Points | Easy To Operation |

| Motor Type | AC Motor |

| Capacity(t/h) | Customized |

| Color | Customized |

| Price | Negotible |

| Factory visit | Warmly Welcomed |

| Advantage | Easy To Operation |

| Application | Stone Sand Washing |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

Product Description

Specification

Model | Diameter (mm) | Slot length(mm) | Capacity (t/h) | Speed of rotation (r/min) | Motor power (kw) | Weight (t) |

XSL-500 | 500 | 5000 | 12-20 | 32 | 3 | 2.5 |

XSL-750 | 750 | 6500 | 40-55 | 26 | 5.5 | 3.8 |

XL-915 | 915 | 7585 | 100 | 21 | 11 | 6.3 |

2XL-915 | 915 | 7585 | 200 | 21 | 2*11 | 11 |

XL-1115 | 1115 | 9782 | 175 | 17 | 15 | 10 |

2XL-1115 | 1115 | 9782 | 350 | 17 | 2*15 | 18 |

XL-1500 | 1500 | 10300 | 15-200 | 10.5 | 15 | 16 |

The working principle of the spiral sand washing machine

The material falls vertically into the rotating impeller from the part of the sand washing machine. Under the action of centrifugal force, it collides with the other part of the material that flows in an umbrella shape around the impeller. After colliding with each other, the materials will form eddy currents between the impeller and the casing, which will collide with each other and be crushed by friction for many times, and discharged through the lower part to form a closed cycle. The required particle size of the finished product is controlled by the screening equipment.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

The advantages of the spiral sand washing machine

1. Large handling capacity : able to efficiently handle a large number of materials.

2. Small power consumption : Compared with other sand washing equipment, the power consumption of spiral sand washing machine is lower.

3. High degree of cleanliness : through many cycles and impact, friction, can achieve a high degree of cleanliness.

4. Good sealing structure : the use of fully closed transmission device and adjustable overflow weir plate to ensure good cleaning, dehydration effect, fine products to maintain stability .

The product characteristics of spiral sand washing machine

1. Reasonable structure : reasonable design, convenient maintenance.

2. Durable : The fully enclosed oil-bath transmission ensures the durability of the equipment.

3. Good cleaning effect : through reasonable sealing structure and transmission device design to ensure that the cleaning and dehydration effect is good .

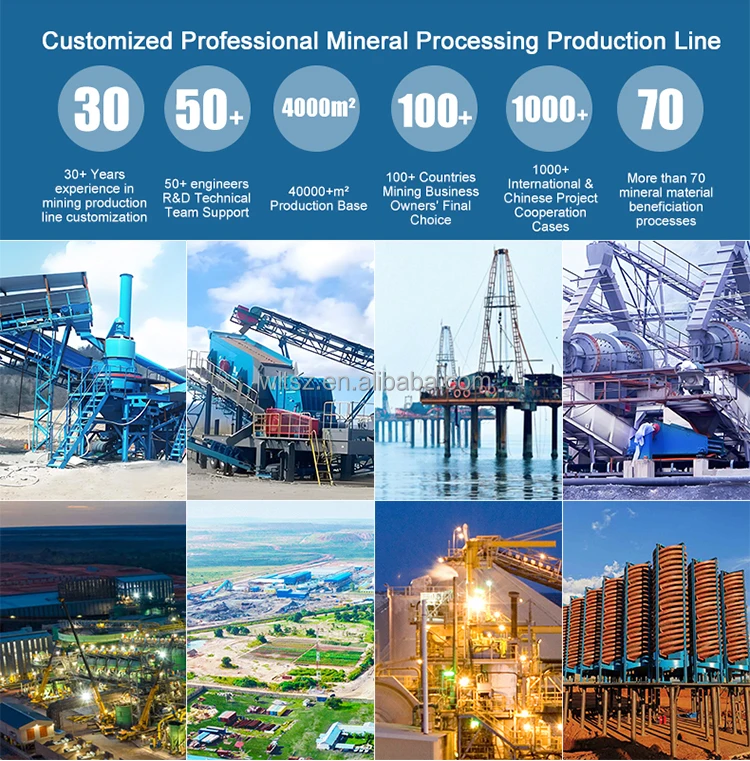

Company Profile

Company Profile: Future Explorer Technical Eqiupment Co.,Ltd (FETECH)

The R&D technical team is located in Shenzhen, Guangdong,a high-tech industry gathering city in China. The factory is located in Shicheng County, Jiangxi Province, covering an area of around 40,000m².

It has more than 200 sets of large-scale modern mechanical processing equipment, smelting and casting equipment, and more than 50 professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation engineers, including 10+ senior engineers, 30+ junior engineers, and 150+ workers.supporting our company's strong production and supply capabilities.

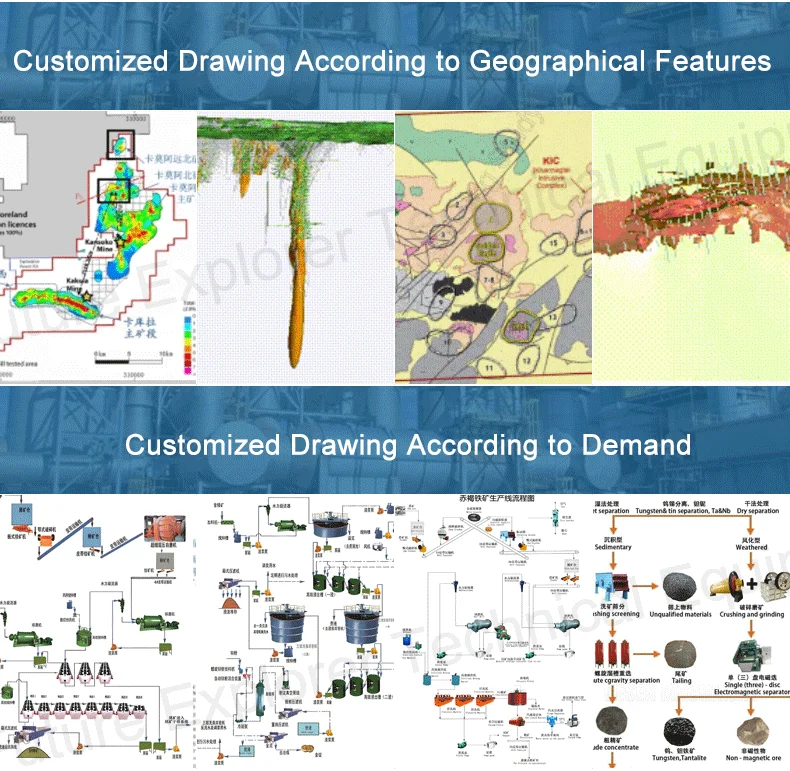

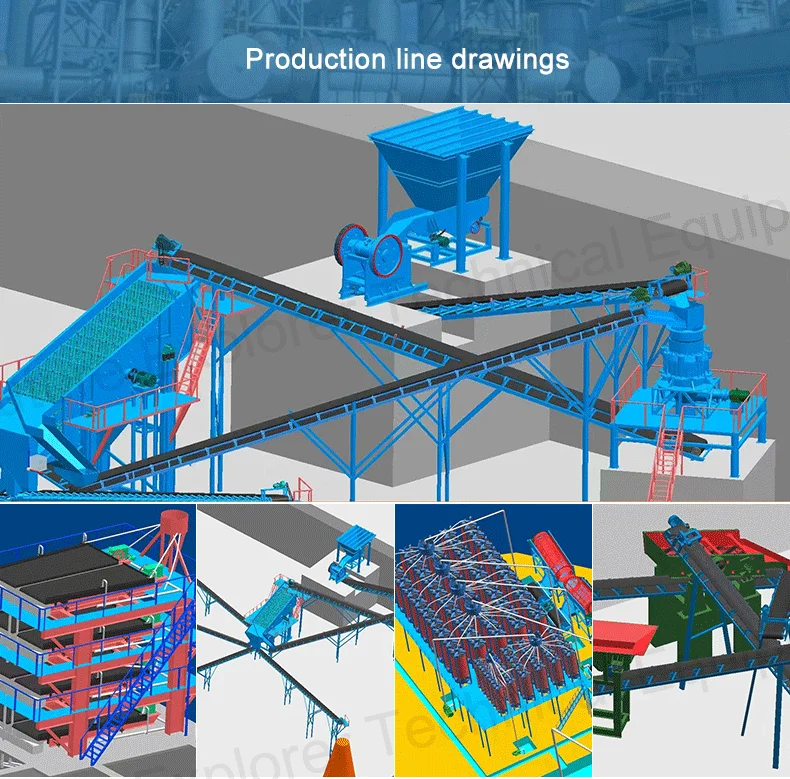

For more than 20 years, we have focused on the R&D, design and production of mining mineral processing equipment. The core founding team has independently designed and developed customized production line one-stop solutions for mining projects in 100+ countries around the world based on customer needs and the local geographical environment of the mine. Including on-site survey, product design, manufacturing, installation, commissioning and after-sales service. In addition,We also maintain long-term cooperation with international and Chinese scientific research institutions of universities to explore new and efficient technologies, improving economic efficiency while protecting the environment

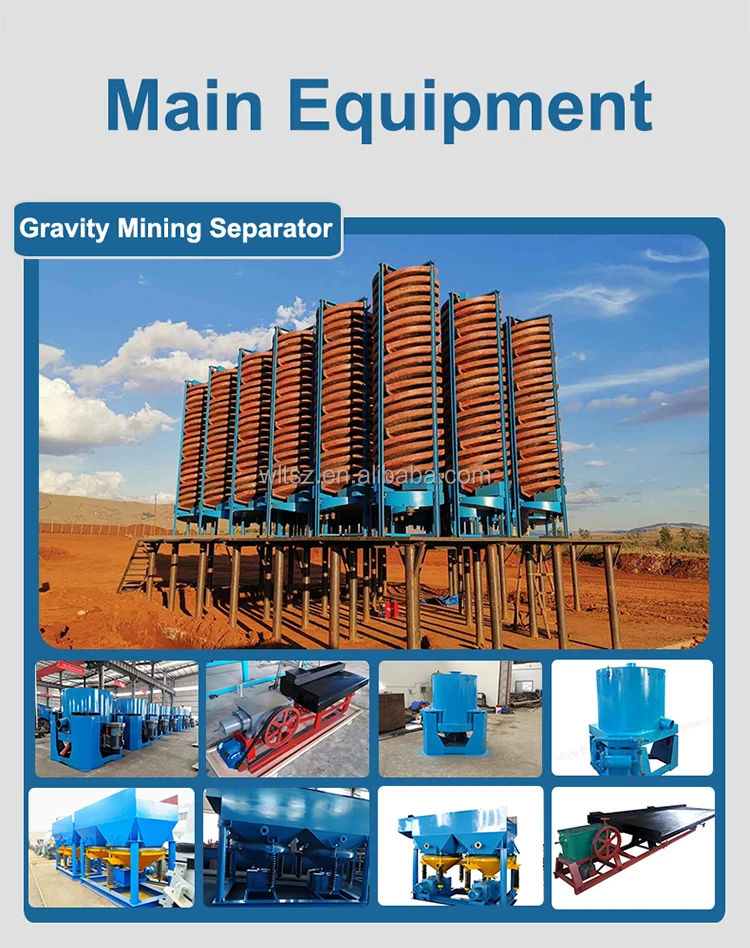

Main products: customized production line solutions for mines, ore washing equipment, gravity separation equipment, flotation equipment, magnetic separation equipment, crushing and grinding equipment, screening and classification equipment, feeding and conveying equipment, mineral processing experimental equipment, excavation equipment and transportation equipment , mobile mining crushing production equipment, sand dredgers, dredgers and other large equipment. Mainly used in mining, coal, quarry, scrap metal recycling and other fields.

Products have passed ISO9001, ISO27001, ISO17020, SGS, IECEX, MSHA, ATEX, ANZEX, CERTEX, GOST-R, IRMA certification

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

30+Years experience in mining production line customization

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

We support EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )

Global Sales Network:

1. Oceania: Australia, New Zealand 2.Africa: South Africa, Sudan, Zimbabwe, Ghana,Tanzania, Uganda, Congo, Zambia, Nigeria,

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Customer Photos

Certifications