FEtech Compound Crushing PFL-2000 High Quality Stone Crusher Sand Making Machine Vertical Shaft Compound Crusher.

US $56,800.00-57,000.00 / set

1 set(s)Minimum order

Type:

Crusher Separtor

Production Capacity:

Customized

Place of Origin:

Jiangxi, China

Brand Name:

FEtech, FEtech

Voltage:

380V, 220V

Dimension(L*W*H):

Customized, Depend on model

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Crusher Separtor |

|---|---|

| Production Capacity | Customized |

| Place of Origin | Jiangxi, China |

| Brand Name | FEtech, FEtech |

| Voltage | 380V, 220V |

| Dimension(L*W*H) | Customized, Depend on model |

| Weight | 45000 KG |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | motor, Bearing, PLC, Other, Engine |

| Key Selling Points | Easy to Operate |

| Product name | Compound Crushing |

| Application | stone,ore,sand |

| Keywords | Crusher Machine |

| Color | As your request |

| Quality | Long service life |

| Capacity | Customized |

| Price | Negotiable |

| Advantage | Good quality,Saving cost,Easy Operation |

Product Detail

Product Description

Specification

Type | Max. Feeding size (mm) | Output Granularity(mm) | Spindle Speed(r/min) | Processing capacity (t/h) | Power(kw) | Total weight (t) |

PFL-800 | 100 | 0.5-5 | 800-1350 | 8-20 | 37 | 4.5 |

PFL-1000 | 120 | 0.5-5 | 600-980 | 15-40 | 55 | 6.5 |

PFL-1250 | 150 | 0.5-5 | 500-800 | 35-50 | 90 | 9.5 |

PFL-1500 | 180 | 0.5-5 | 400-650 | 50-80 | 132 | 13.6 |

PFL-1750 | 200 | 0.5-5 | 420-550 | 70-100 | 160 | 17.5 |

PFL-2000 | 220 | 0.5-5 | 350-500 | 90-130 | 200 | 24.7 |

PFL-2300 | 240 | 0.5-5 | 330-450 | 120-160 | 250 | 30 |

PFL-2500 | 260 | 0.5-5 | 300-400 | 150-200 | 315 | 36 |

Working principle:

Compared with other types of sand-making equipment, the working principle of compound sand-making machine has almost no difference. All materials fall vertically from the upper part of the inlet port of the equipment through the feeder. Under the centrifugal force produced by the high-speed rotation of the impeller, the material diverted around the impeller in the form of umbrella produces high-speed impact and crushing. After colliding with each other, it will be in the impeller and the shell again. In the meantime, eddies formed by materials collided and rubbed against each other for many times, and were discharged directly from the lower part.

Advantages:

Uniform particle size: through multiple impacts and grinding, the particle size of the finished material is more uniform, which meets the requirements of various engineering construction and industrial production, and improves the quality and stability of the product.

Good grain shape: The sand produced is a cube, the accumulation density is large, the iron pollution is minimal, and the application effect is better in concrete and other building materials, which can improve the strength and stability of concrete.

Application:

Metallurgical industry: used for metallurgical slag crushing and recycling, the slag broken into reusable particle size, used in road base, fill engineering, etc., to achieve the recycling of resources, reduce production costs, while reducing environmental pollution.

Water conservancy and hydropower engineering: Used in the production of sand and stone aggregate in water conservancy and hydropower engineering, to provide high-quality sand and stone aggregate for concrete DAMS, hydropower station buildings and other buildings to ensure the quality and safety of the project.

Company Profile

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

20+Years experience in mining production line customization

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

We support EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )

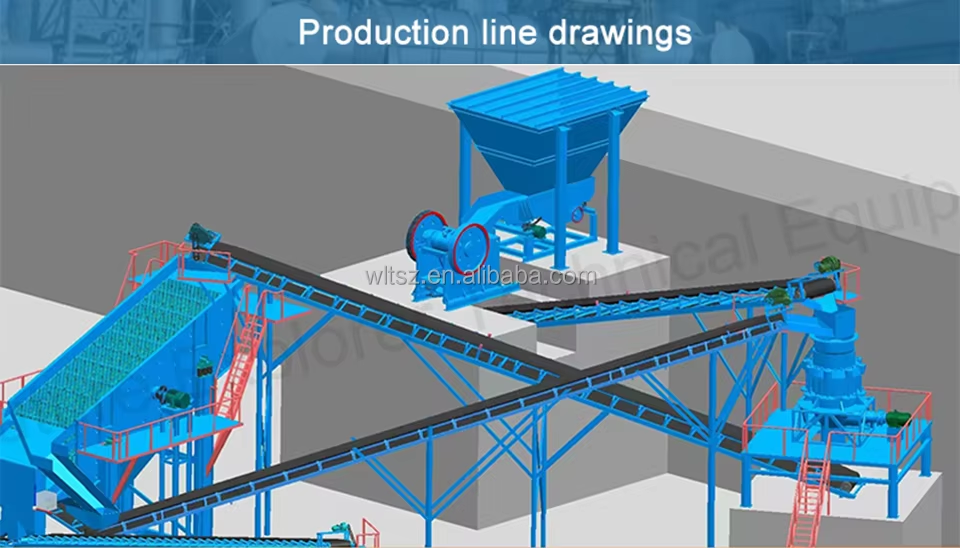

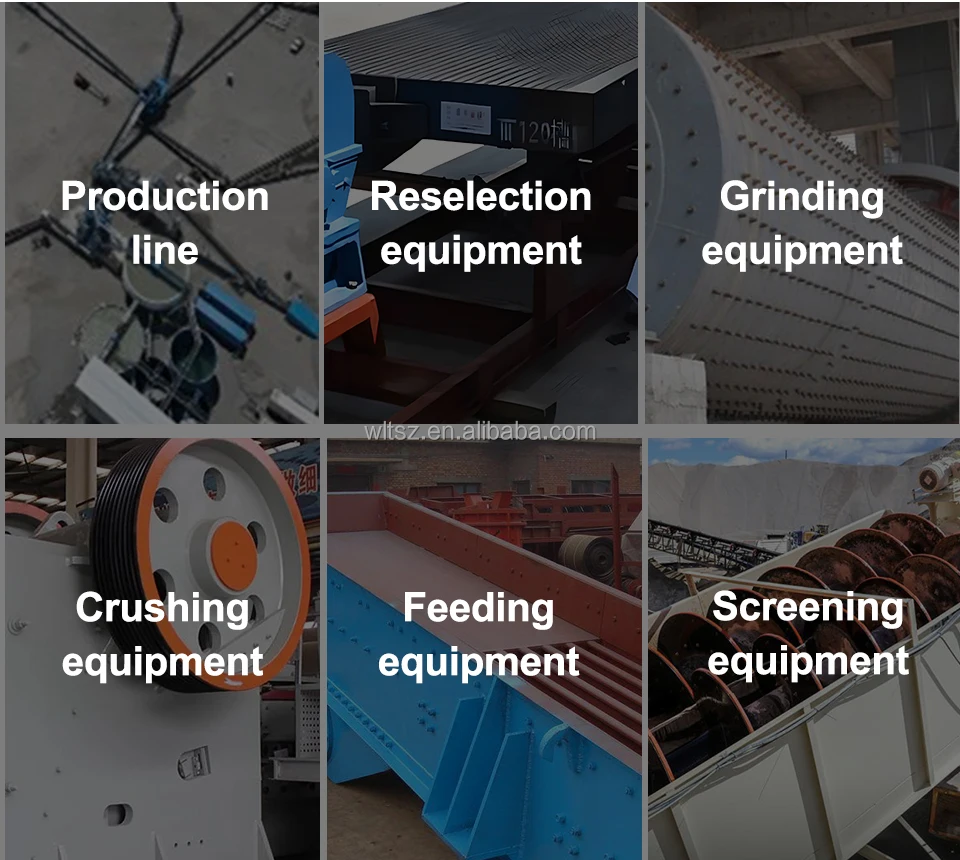

Product classification

Manufacturing

Certifications

24/7/365 Service