Factory Delivery Fire Fighting Grooved Mechanical Tee Ductile Iron Pipe Fitting Coupling Flexible

US $1.22-1.35 / piece

10 piece(s)Minimum order

warranty:

3 years

customized support:

OEM, ODM, OBM

place of origin:

Shandong, China

brand name:

LBC

model number:

1''-12''

Technic:

Casting

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| warranty | 3 years |

|---|---|

| customized support | OEM, ODM, OBM |

| place of origin | Shandong, China |

| brand name | LBC |

| model number | 1''-12'' |

| Technic | Casting |

| Connectivity | Grooved |

| shape | Coupling |

| head code | Grooved Coupling |

| Product name | Rigid Couplings |

| Material | Ductile Iron |

| Application | Fire Fighting System |

| Color | Red Orange Blue Grey White |

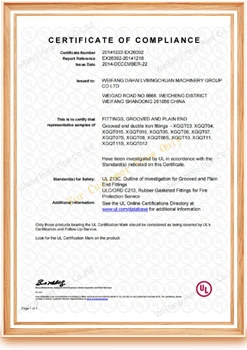

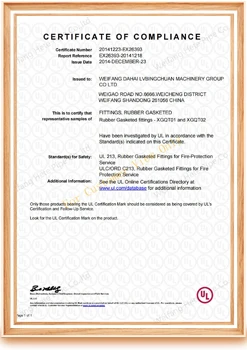

| Standard | FM UL ISO9001 CE |

| Connection | Grooved |

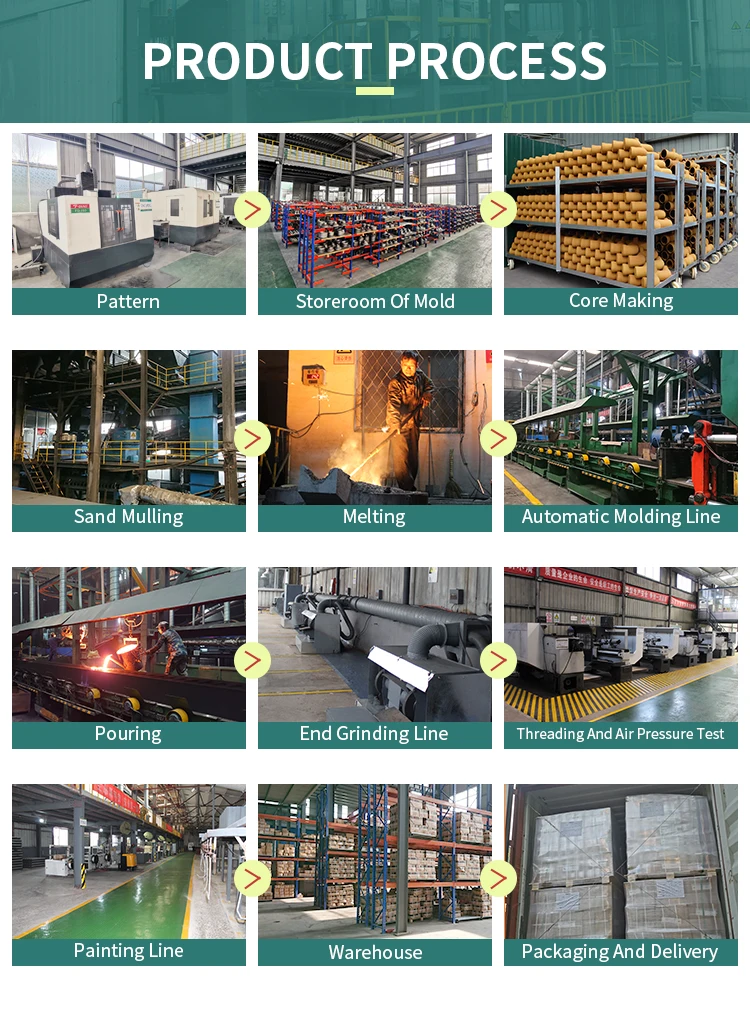

Product Detail

Product Name | Grooved Couplings |

Size | 1"-12" |

Material | Ductile iron |

Application | Fire Fighting System |

Standard | FM UL |

MOQ | 50pcs |

01 Source protection

Secured input Source: all

materials must pass the quality checking, otherwise must be returned.

02 Reliable fittings

Reliable Components: Allbolts&nuts, gaskets and packing materials must be checked on the inbound.

03 High quality molten iron

High Standard of Melting Process: every forge of melted iron must go through the CE chemical analysis before the casting process.

04 Spheroidization analysis

Nodular Level Analysis: all

casted pieces must reach

Nodular Level Grade 3(above

85%).

05 Metallographic composite

Metallographic Checking:

100% double checked,100%

insurance of spheroidization.

06 Chief diagnosis

Production Transaction Checking:all products must be personally checked by the engineers and workshop managers before transferring to next process.

07 Black parts single inspection

Black Parts QC: Every single piece must pass black part QC checking,zero tolerance on sand holes.

08 Air tightness detection

Airtight Detection: Every piece of fittings shall be tested in the seal tests.

09 Size detection

Dimension:daily random

checking.and sampling

inspection of each production.

10 Mechanical performance testing

Mechanical Performance Examination:Random sampling based on CCCf. FM and UL standards, daily destructive pressure test(10 Mpa),stable hydraulic test and torque test must be performed.

11 Coating each inspection

Visual Checking of Coating:piece by piece, delicate and professional.

12 6s sampling inspection

6S Patrol Checking:as least 3 times of random sample checking by 6S patrol team per week.

Welfang Hete Pipe Co., Ltd., which is located in a beautiful city called Welfang known as the famous World Kite Capital, Is one of the largest subsidiary companies of Welfang Dahal Lvbingchuan Machinery Group. The company Integrates the product development, design, casting, machining, coating, packing and transporting of grooved plpe fittings and coupling through all grooved product life circle. Hete Is also dedicated in developing relative components of grooved pipe system in the modern soclety.

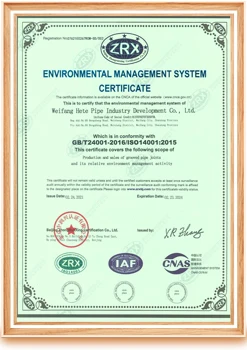

Right now, Hete Company owns one R&D center with sufficlent equlpment and several quallty & metallographic laboratories, with more than 110 employees sustaining a high value production capability at the top of the grooved fittings & couplings industry. Since established, the Hete Company has won the awards of "Honest Enterprise" among all the private enterprises in Welfang City for many years in rows, and has passed IS09001 quallty system certification.Also, Hete has successfully passed the US FM Approval certification and Hete Brand has successfully been listed in UL certifled list.

Hete Company mainly produces grooved pipe connectors and all kinds of plastic-coated pipes connecting components, such as grooved fittings and couplings for firefighting system, sprinkler system, and drinking water pipe system. And Hete Company Is one of the most professional and major manufacturers of grooved pipe fittings and couplings In China domestic market. Based on the business developing strategy of advance starting level, high standard, premium requirement and massive scale, strictly following the GB5135.11-2006 natlonal standards, Hete has acquired an International advance level In casting technologles of Ductile Iron. Mearwhile, Hete has been the first to use electronic furnace which Is much more reliable for temperature control. Hete products are good both in surface out-look and stable quality, and has been recommended by China Assoclation for Engineering Construction Standardization.Hete's products have been widely Installed on flrefighting systems, water pipe system, draining system, electronic and oil system all over the country, as well as far away abroad like Saudl Arabla, Russla, USA, Korea, Brazil and Italy et al.

Using the high extend rate material QT450-12 Ductile Iron, every single plece of Hete products will be checked with metallographic and mechanical performance tests before delvery,

Including all the gaskets, to ensure the seal capacity under great pressure.

Hete Company has always bolleve in the concept of "Customer is like parents who support us to grow up, and the quality we supply is our ille". Hete will keep on exploring in the overseas and domestic markets and improving services skills, so that Hete can move forward with all clients in the world to create a better future.

For more information,please inguire directly.