Factory Price Stainless Steel Colloid Mill/ Peanut Butter Making Machine

US $1,957.00-2,059.60 / set

1 set(s)Minimum order

weight (kg):

175

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

motor

place of origin:

Henan, China

brand name:

LIANGPU

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| weight (kg) | 175 |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | motor |

| place of origin | Henan, China |

| brand name | LIANGPU |

| type | colloid mill machine |

| warranty | 1 Year |

| application fields | Vegetable processing plant, Meat processing plants, Commercial catering, Snack food factory, Fruit processing plant, Cooking oil factory, Frozen food Factory |

| machinery capacity | 300-500 kg/h |

| machinery function | colloid mill machine |

| Product name | colloid mill machine |

| Model | LP-JM130 |

| Power | 11kw |

| Capacity | 300-500 kg/h |

| Fineness | 80-200 mesh |

| Weight | 285 kg |

| Machine Size | 990*440*1000 mm |

| Material | Stainless steel |

| Function | food colloid mill |

| Machinery Function | sesame colloid mill |

| Condition | New |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Applicable Industries | hotels, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Food Shop, Other |

Product Detail

Product Overview

Factory Price stainless steel colloid mill/ peanut butter making machine

This colloid mill is widely applied in the industrial productions of food (Peanut butter, sesame jam, chilli paste, garlic paste, apple paste, rice milk, soy milk, dairy products, soft drinks and etc.), medicine (syrups, nutrition liquid, Chinese herb extracts, poultice and etc.), daily chemical products (tooth paste, cosmetic, washing agent and etc.), chemical industry products (pigment, dye, dope, lubricant, petroleum activator and etc.) and the flotation and emulsification of the explosives.

PRODUCT SPECIFICATIONS

Model | Power | Capacity | Fineness | Weight | Machine Size |

LP-JM50 | 1.5kw | 10-15 kg/h | 50-100 mesh | 50 kg | 530*260*580 mm |

LP-JM80 | 4kw | 60-80 kg/h | 80-150 mesh | 150 kg | 600*410*930 mm |

LP-JM110 | 7.5kw | 100-200 kg/h | 80-150 mesh | 175 kg | 700*430*1000 mm |

LP-JM130 | 11kw | 300-500 kg/h | 80-200 mesh | 285 kg | 990*440*1000 mm |

LP-JM180 | 18.5kw | 700-800 kg/h | 80-200 mesh | 375 kg | 1000*490*1100 mm |

LP-JM240 | 45kw | 1200-1500 kg/h | 100-200 mesh | 920 kg | 1330*630*1280mm |

LP-JM300 | 75kw | 3000-4000 kg/h | 100-200 mesh | 1300 kg | 1500*800*1120mm |

Video Description

Product Features

1. The main parts are made of high-quality stainless steel, corrosion-resistant and non-toxic.

2. The main working parts, rotor, using special machining and heat treatment technology, high processing precision, long service life.

3. The rotor can be selected from different materials, equipped with different structures and tooth types such as grinding and cutting, the user can choose according to needs, and has wide applicability.

4. The processing gap is micro-adjusted through the adjustment ring, which is easy to control and ensure the processing quality of the product.

5. The main seat and adjusting ring are equipped with a limit and locking device to ensure the stability of the processing gap.

6. Equipped with cooling system to ensure the nature of processed materials.

7, the product design has the structure of ordinary inlet and outlet material, tubular inlet and outlet material and recycling processing, to meet the requirements of users to the maximum extent.

8. Users can choose ordinary motor or explosion-proof motor according to their needs.

9. The whole machine design has a variety of outer packaging forms, available for users to choose.

10, spindle and motor separate design, users can choose the appropriate speed according to needs.

2. The main working parts, rotor, using special machining and heat treatment technology, high processing precision, long service life.

3. The rotor can be selected from different materials, equipped with different structures and tooth types such as grinding and cutting, the user can choose according to needs, and has wide applicability.

4. The processing gap is micro-adjusted through the adjustment ring, which is easy to control and ensure the processing quality of the product.

5. The main seat and adjusting ring are equipped with a limit and locking device to ensure the stability of the processing gap.

6. Equipped with cooling system to ensure the nature of processed materials.

7, the product design has the structure of ordinary inlet and outlet material, tubular inlet and outlet material and recycling processing, to meet the requirements of users to the maximum extent.

8. Users can choose ordinary motor or explosion-proof motor according to their needs.

9. The whole machine design has a variety of outer packaging forms, available for users to choose.

10, spindle and motor separate design, users can choose the appropriate speed according to needs.

11. Standard motor.

12. The sealing form has ordinary sealing sleeve sealing and mechanical sealing, the user can choose according to the need.

12. The sealing form has ordinary sealing sleeve sealing and mechanical sealing, the user can choose according to the need.

PRODUCT CONFIGURATION

Outlet 1: Circulating pipe

Suitable for low-viscosity materials that need reflux or grinding,such as fruit juice,soy milk,etc.

Outlet 2: Square

Suitable for high and medium viscosity materials that don't need reflux or grinding,such as peanut butter,chilli sauce,etc.

Grinding fineness control handle

Adjustable grinding fineness, turn clockwise for finer grinding, and counterclockwise for coarser fineness

Stator and rotor

Stable performance and high discharge fineness

Cooling water pipe

Cooling temperature by water

Details Images

Product packaging

In order to allow customers to have a better consumption experience, our company will package each Installing waterproof membrane to reduce dust and water pollution,product in a wooden box or iron frame,and the packaging requirements are in line with international standards.

Company Information

FAQ

Question 1: Which ports do you usually ship at?

Answer: We can load container at: Qingdao, shanghai, Ningbo, Tianjin, Guangzhou etc.

Question 2 :What is your mode of transportation?

Answer: A: Express, air and sea.

Question 3: Can I print my company logo on the machine?

Answer:Yes, sure.

Question 4: Can you customize the machine for me ?

Answer: Yes, we can customize according to customer's requirements.

Question 5: What shall we do if breakdown occurs?

Answer: we can teach you install or maintain the machine by video, email ,pictures.....if large project , we can arrange our engineer help you to install or maintain it in your country. If you need spare parts, we can supply for free or cost price, you pay express cost.

Question 6:What are your terms of payment?

Answer:T/T,Credit card, Western Union, RMB,Alipay, Cash, E-checking, MoneyGram,L/C,etc.

Answer: We can load container at: Qingdao, shanghai, Ningbo, Tianjin, Guangzhou etc.

Question 2 :What is your mode of transportation?

Answer: A: Express, air and sea.

Question 3: Can I print my company logo on the machine?

Answer:Yes, sure.

Question 4: Can you customize the machine for me ?

Answer: Yes, we can customize according to customer's requirements.

Question 5: What shall we do if breakdown occurs?

Answer: we can teach you install or maintain the machine by video, email ,pictures.....if large project , we can arrange our engineer help you to install or maintain it in your country. If you need spare parts, we can supply for free or cost price, you pay express cost.

Question 6:What are your terms of payment?

Answer:T/T,Credit card, Western Union, RMB,Alipay, Cash, E-checking, MoneyGram,L/C,etc.

Question 7:How long is the shelf life of the product

Answer: Quality guarantee term is for one year, During guarantee period, free technical support and free spare parts supply.

Question 8:What's the minimum quantity of an order?

Answer: Usually 1 set, or based your order, Preferential wholesale price.

Answer: Quality guarantee term is for one year, During guarantee period, free technical support and free spare parts supply.

Question 8:What's the minimum quantity of an order?

Answer: Usually 1 set, or based your order, Preferential wholesale price.

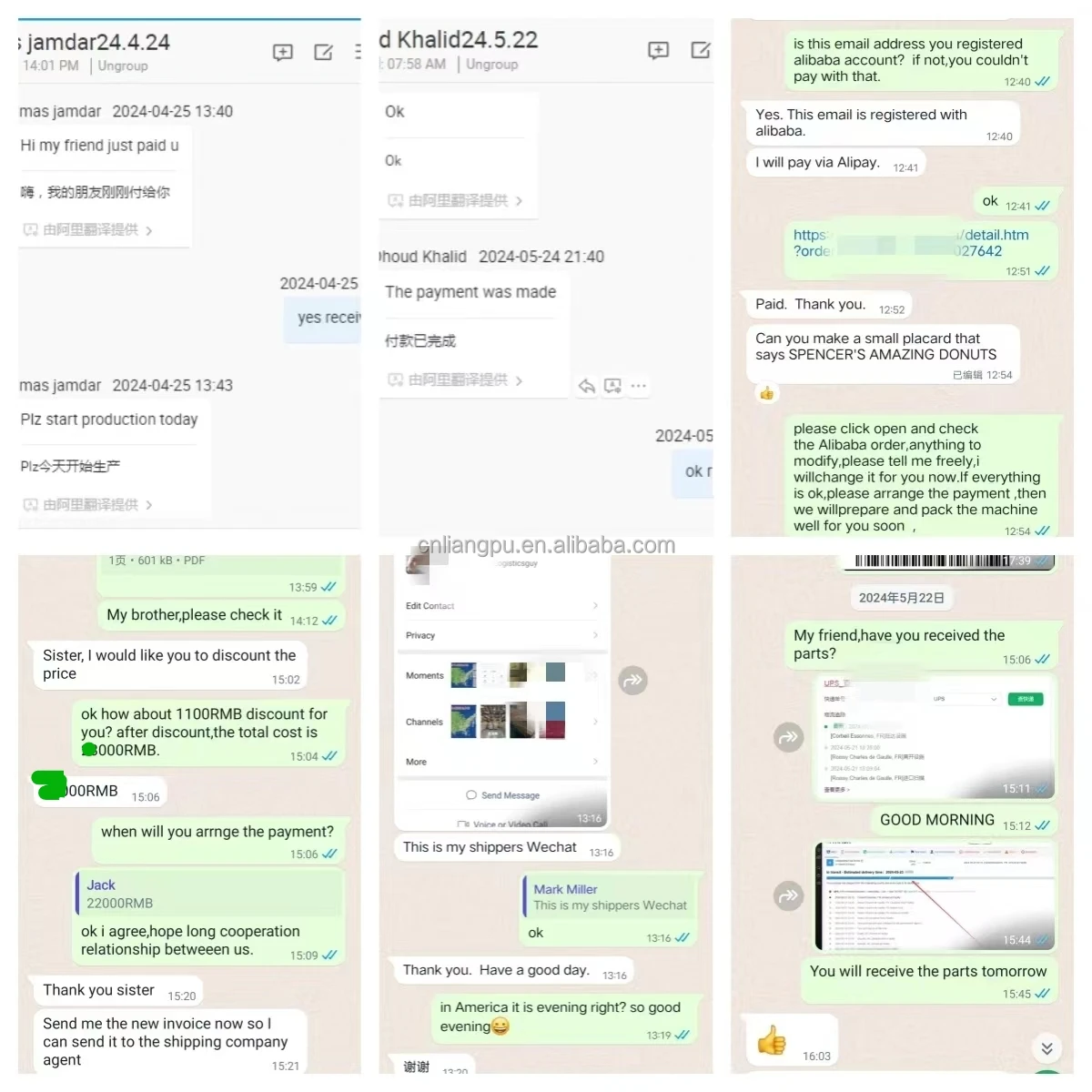

Customer Evaluation

Our Service

Before sales | 24 hours online service. Any inquiries will be replied within 12 hours. offer professional machine details and information. technology knowledge share. |

On sale | Protect the client payment security. reasonable price and ensure quality. send machine pictures , videos as client need and let client know machine more better. |

After sales | Fast delivery and test and adjust machine working well before delivery. Supply manual book and technical support in order to use well. offer install pictures step by step or videos and dispatch the engineer. Guarantee time is one year . during one year . offer the spare parts for free. |

Welcome to contact us for more information!