Froth Floatation Machine for Sale / KYF Pneumatic Flotation Cell

Other recommendations for your business

Contact us

Quik Detail

| Type | Flotation Separator |

|---|---|

| Production Capacity | 99% |

| Place of Origin | Henan, China |

| Brand Name | HONGJI |

| Voltage | Clients Local Standard |

| Dimension(L*W*H) | depend on model |

| Weight | 2000 KG |

| Warranty | 2 years |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Bearing, motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox |

| Key Selling Points | Energy saving |

| Product name | Professional Manufacturers Flotation Mineral Processing Engineering |

| Color | Customers' Requirements |

| Spare parts | supply all year round |

| Installation | Technical Guidance |

| Trough capacity | 0.37-8m3 |

| Blade diameter | 300-760mm |

| Production capacity | 0.2-8m3/min |

| Blade rotation speed | 191-352r/min |

| Showroom Location | Turkey, Philippines, Brazil, Saudi Arabia, Indonesia, South Africa, Kazakhstan, Uzbekistan |

| Condition | New |

| Marketing Type | New Product 2020 |

| Warranty of core components | 2 years |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Energy & Mining, gold or ore mining |

Product Detail

Froth Floatation Machine For Sale / KYF Pneumatic Flotation Cell

Introduction

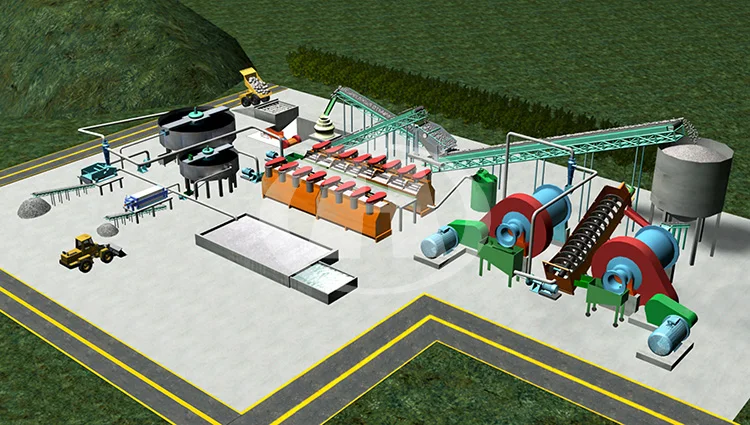

With the development of mining industry, investors present various requirements of the features of flotation machine. Now there are many kinds of flotation machines in Hongji, such as agitator flotation machine, pneumatic flotation machine and pneumatic- agitator flotation machine. And different mineral ores have different hydrophilicity, so the final configurations greatly depend on the professional designs.

Application of Flotation Machine

Flotation machine are mainly used in mineral ore dressing plants, selecting the valuable mine from gangue. It is applicable for the separation of numerous of mineral ores, such as fluorite and talc, gold ore, copper ore, iron ore and zinc ore and so on.

Features of Flotation Machine

1. Large air-absorption capacity and low energy consumption

2. Optimistic structure design & Excellent performance

3. Reasonable circulation of mineral slurry

4. Automatic control Easy to adjust

| SF Model | Diameter (mm) | Rotational Speed (r/min) | Capacity (m³/min) | Main Motor | Scraper Motor | Size (mm) | ||

| Model | Power (kw) | Model | Power(kw) | |||||

| SF0.15 | 200 | 536 | 0.06-0.18 | Y100-6 | 1.5 | Y80L-4 | 0.55 | 500×500× 600 |

| SF0.37 | 296 | 386 | 0.2-0.4 | Y90L-4 | 1.5 | Y80L-4 | 0.55 | 700×700× 750 |

| SF-1.2 | 450 | 312 | 0.6-1.2 | Y32M-6 | 5.5 | 90S-4 | 1.1 | 1100×1100× 1100 |

| SF-2.8 | 550 | 268 | 1.5-3.5 | Y180L-6 | 11 | Y100L6 | 1.5 | 1700×1600× 1150 |

| SF-4 | 650 | 220 | 2-4 | Y200L-8 | 15 | Y100L6 | 1.5 | 1850×2050× 1200 |

| SF-8 | 760 | 191 | 4-8 | Y250M8 | 30 | Y100L6 | 1.5 | 2200×2900× 1400 |

| SF-10 | 760 | 191 | 5-10 | Y250M8 | 30 | Y100L6 | 2.2 | 2200×2900× 1700 |

| JIF-4 | 410 | 305 | 2-5 | Y160L-6 | 11 | Y100L6 | 1.5 | 1600×2150× 1250 |

| JIF-8 | 540 | 233 | 4-10 | Y200L26 | 22 | Y100L6 | 1.5 | 2200×2900× 1400 |

| JIF-10 | 540 | 233 | 4-12 | Y200L26 | 22 | Y100L6 | 2.2 | 2200×2900× 1700 |