Full Automatic PE PP Film Scraps Plastic Washing Machine Line Plastic Recycling Line

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Jiangsu, China |

|---|---|

| brand name | REGULUS |

| automatic grade | Semi-automatic |

| equipment list | Trommer, Pre-washer, Dewatering Machine, Floating Washing Tank, Hot Air Dryer, Frication Washer, Hot Washing Tank, Crusher/Granulator |

| max.production capacity (kg/h) | 2000 |

| voltage | 3phase, 380V, 50Hz or custom-made |

| dimension(l*w*h) | different size according to different model |

| power (kw) | different according to different model |

| weight (t) | 10 |

| warranty | 1 Year |

| key selling points | Competitive Price |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Gear, Pump, crusher blade, washer shaft, electric parts |

| Recycling plastic type | waste PE, PP, HDPE, LLDPE, LDPE |

| Final product | clean and dry plastic pieces |

| Water consumption | 3-8 Ton/ Hr, water can be reused |

| Motors brand: | Seimens Beide |

| Contactor: | Schneider or Siemens Brand |

| Bearing Brand: | NSK |

| Inverter: | ABB Brand |

| Next step machine | plastic extruder pelletizing line |

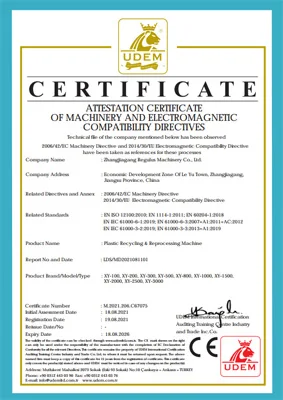

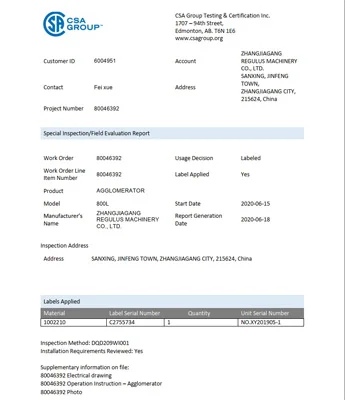

| Certification | ce |

| Related products | crusher, shredder, dryer |

| Condition | New |

| Plastic Type | PP/PE |

| Machine Type | PP PE Film Washing Line |

| Showroom Location | Canada, Turkey, United Kingdom, United States, Germany, Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Russia, Spain, Thailand, Morocco, Argentina, South Korea, Chile, UAE, Colombia, Sri Lanka, Romania, South Africa, Ukraine, Japan, Malaysia, Australia |

| Warranty of core components | 1 Year |

| Application | recycle plastic PE PP |

| Production Capacity (kg/h) | 300 - 2000 |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Printing Shops, Construction works , Other, plastic recycling factory, plastic bag making company |

Product Detail

production line is mainly composed of the following equipment: belt conveyor, crusher, friction cleaning machine, film rinsing machine, screw feeding machine, heat cleaning machine, screw feeder, dehydrator, drying system, electrical and so on. The equipment is simple, practical and high yield, which is the most effective production line for recycling waste plastics.

plastic bags, injection products, wood plastic products, etc., and has a wide range of uses.

The shape, size, moisture content, and impurity content of the waste film are not the same. The types of plastic films commonly found in the recycling market are:

1. Production of post-consumer films (including collected from landfills and selectively collected)

2. Commercial and post-industrial films (mainly in plastic bags and packaging films, stretch film)

3. Agricultural film (including greenhouse, mulch, greenhouse film and banana film, etc.)

Mainly in Plastic PE, PP, LLDPE, HDPE, LDPE.

Model | Product capacity | Motor power | Equipment footprint | |||

PEW-300 | 300 kg/h | 100 kw | 120 m2 | |||

PEW-500 | 500 kg/h | 150 kw | 200 m2 | |||

PEW-1000 | 1000 kg/h | 190 kw | 310 m2 | |||

PEW-1500 | 1500 kg/h | 250 kw | 500 m2 | |||

PEW-2000 | 2000 kg/h | 290 kw | 600 m2 | |||

▲ CE certification available. ▲ Larger, more powerful models available based on your request. | ||||||

The entire plastic PE PP washing line is controlled via a central electric control panel and cabinet.

The shredder is usallyequipped for large capacity washing line, and the shredder can shred whole film bales directly.

The plastic granulator cuts the plastic into smaller pieces. Crush with water which can clean the dirty waste plastic before moving onto the next washing machine.

The friction washer is high rotating speed cleaning equipment. The plastic runs against each other at high speed geeting rid of hard to remove contamination.

In the washing tank, the plastic PP and PE will float, and heavier contamination such as dirt , sand , glass ,metals , other plastics will sink .

The machine uses centrifugal force to remove a large portion of

water within the plastic before moving forward onto the therma dryers.

Another kind of dewatering machine. the screw-press dewatering machine is a more advance version of the standard

dewatering machine. The machine screw press squeezes the water

out via high pressure.