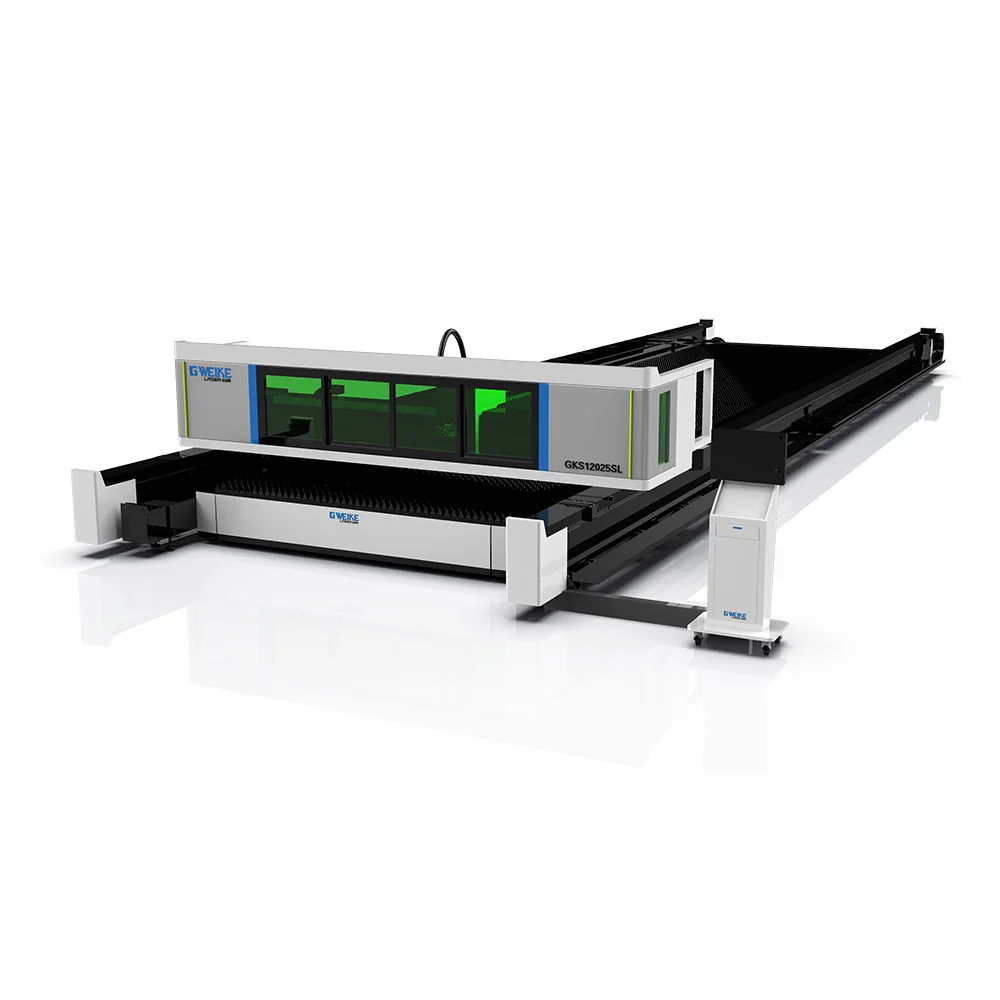

G.WEIKE GKS12025SL SL SERIES ULTRA-LARGE FORMAT SPLIT DESIGN SHEET METAL FIBER LASER CUTTING MACHINE

Other recommendations for your business

Contact us

Quik Detail

| Applicable Material | metal |

|---|---|

| condition | New |

| laser type | Fiber Laser |

| cutting area | 12000mm*2500mm |

| cutting speed | 100m/min |

| graphic format supported | AI, BMP, DXF, PLT, cnc pipe fiber laser cutting machine, Dst, Dwg, LAS, DXP |

| cutting thickness | Determined by selected laser power |

| cnc or not | Yes |

| cooling mode | WATER COOLING |

| place of origin | Shandong, China |

| brand name | G.WEIKE |

| Laser Source Brand | Raycus/IPG |

| laser head brand | Germany PRECITEC Procutter auto focusing / Boci |

| servo motor brand | Inovance |

| guiderail brand | Taiwan Lappong |

| control system brand | Cyput 5000 / Hyput 8000 |

| weight (kg) | 13000 KG |

| Key Selling Points | SL SERIES ULTRA-LARGE FORMAT SPLIT |

| warranty | 3 years |

| mode of operation | continuous wave |

| configuration | bench-top |

| products handled | Sheet Metal |

| feature | Programmable |

| Control Software | Cyput 5000 / Hyput 8000 |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Product name | SL SERIES ULTRA-LARGE FORMAT SPLIT FIBER LASER CUTTING MACHINE |

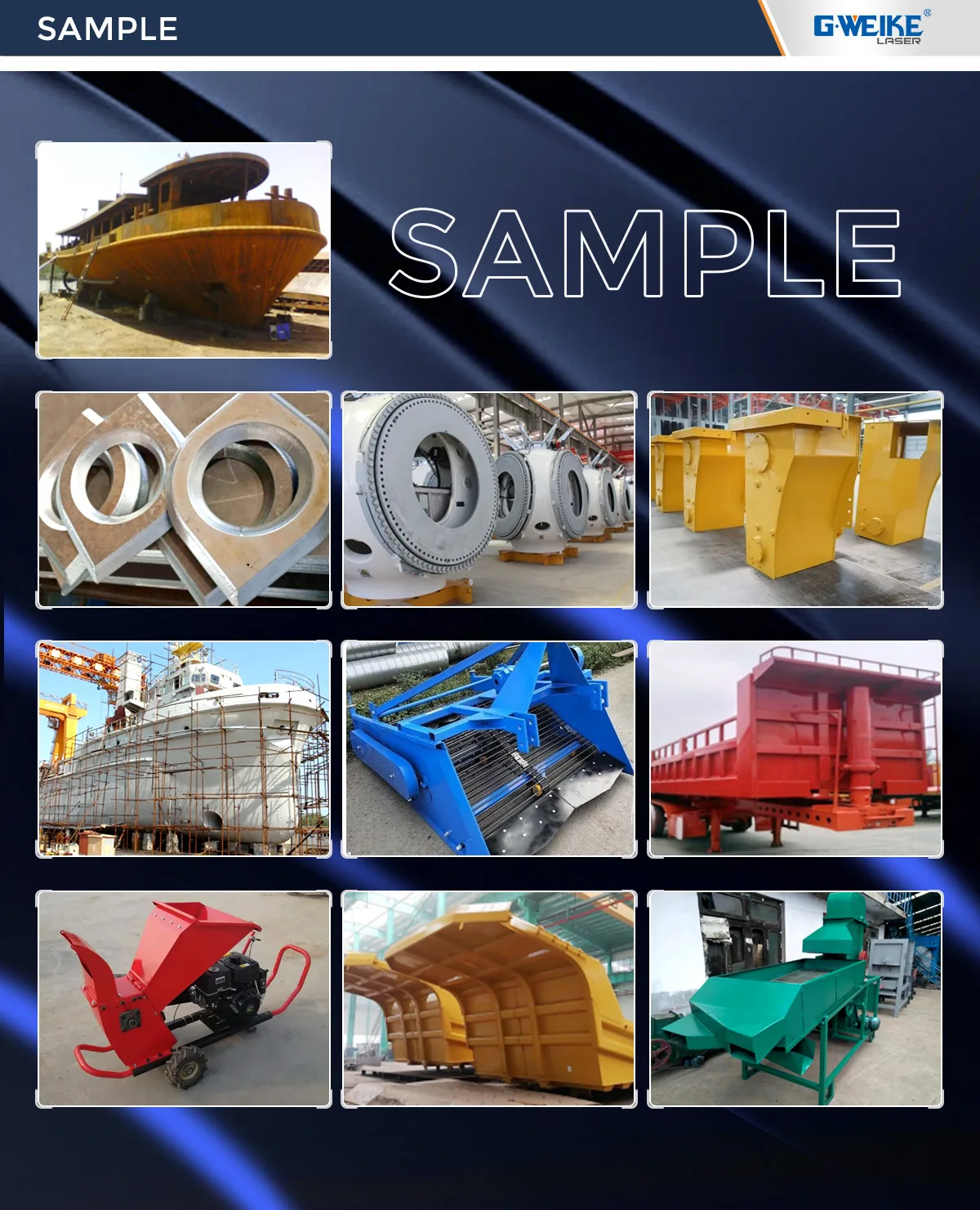

| Application materials | metal plates,stainless steel,carbon steel,brass,aluminum,etc |

| Fiber Laser power | 12000W-30000W |

| Fiber Laser type | Raycus/IPG |

| Voltage and frequency | 380V/50Hz/60Hz/60A |

| Transmission | Double Drive Rack Gear |

| Accuracy | ± 0.03mm |

| Application | LASER CUTTING |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Energy & Mining, Other, Advertising Company |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 3 years |

| Core Components | Pressure vessel, Bearing, Gear, Pump, Gearbox, Engine |

Product Detail

Model | GWK12025SL |

Maximum processing range | 12000×2500mm |

X-axis travel | 2500mm |

Y-axis travel | 12000mm |

Z-axis travel | 270mm |

X / Y axis positioning accuracy | 0.1/10m & 0.05/5m |

X / Y axis repeated positioning accuracy | ±0.05mm |

X / Y axis maximum moving speed | 80m/min |

X / Y maximum cutting speed | 42m/min |

X / Y maximum acceleration | 0.5G |

Transmission type | Dual drive rack |

X axis motor power | 1.3KW |

Y-axis motor power | 2.9KW x 2 |

Z axis motor power | 0.75KW |

Guide rail width | 35MM |

Working platform load | 15000kg |

Enclosed laser protection | Yes |

Lubrication type | Automatic oiling |

Power available | 12000W--30000W |

Dimension | 15130*4430*2000mm |

Total Weight | 13000KG |

GWK12025SL Main Specification | ||||||

No. | Name | Quantity | Brand | |||

1 | Laser source | 1 set | Raycus/IPG | |||

2 | Laser head | 1 set | Germany PRECITEC Procutter auto focusing / Boci | |||

3 | Machine body | 1 set | Gweike | |||

4 | Gear and Rack | 1 set | TAIWAN YYC | |||

5 | Reducer | 1 set | France motoreducer | |||

6 | Motor on X, Y axis | 1 set | Inovance | |||

7 | Motor on Z axis | 1 set | Inovance | |||

8 | Exhaust Smoke System | 1 set | China | |||

9 | Guide rail | 1 set | Taiwan Lappong | |||

10 | Electronic Components | 1 set | France CHNT | |||

11 | Pneumatic Components | 1 set | CKD / Airtac | |||

12 | Control system | 1 set | Cyput 5000 / Hyput 8000 | |||

13 | Water chiller | 1 set | S&A Water Chiller | |||

14 | Control cabinet | 1 unit | GWEIKE | |||

15 | Steel plate welded beam | 1 unit | GWEIKE | |||

16 | Auto higher | 1 unit | Cypcut | |||

17 | Auto lubrication | 1 set | China | |||

18 | Industrial computer | 1 set | HP | |||

19 | Screw | 1 set | TBI | |||

20 | Protective cover | 1 set | GWEIKE | |||

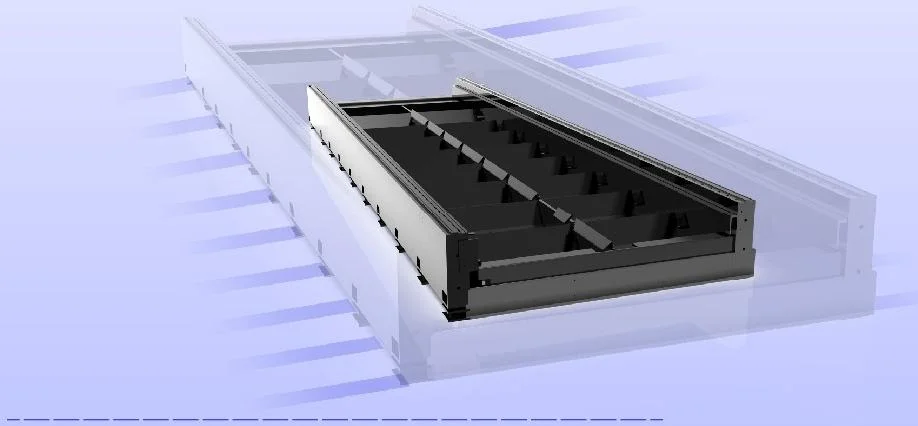

21 | Exchangeable working table | 1 set | GWEIKE | |||

bracket, the bed can be customized and lengthened, and put into production quickly and efficiently.

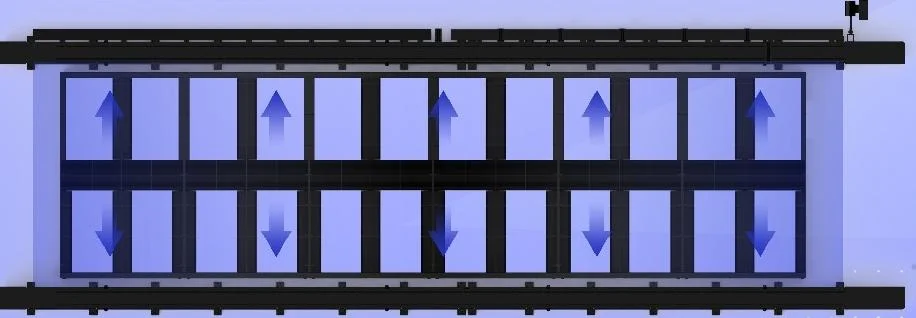

surrounds the downward smoke exhaust 360°and strongly absorbs it; the harmful gas, smoke, and dust are clearly filtered out.

20000W FIBER LASER USING COST | ||||||||

Assisted gas Consumption | Choosel:using air compressor to cutting Stainless steel | Choosell:using O2Cutting Stainless steel | Chooselll:using N2Cutting Stainless steel | |||||

Power Consumption | Laser module | 57kw | 57kw | 57kw | ||||

Water Chiller Group | 20kw | 20kw | 20kw | |||||

Host Machine | 16kw | 16kw | 16kw | |||||

Dust Exhausting Equipment | 11kw | 11kw | 11kw | |||||

Quick-wear Part | 5 RMB/h | 5 RMB/h | 5 RMB/h | |||||

Gas Consumption | 22kw | (About) 40 RMB/h | (About) 150 RMB/h | |||||

Total Power | 126 kw | 104 kw | 104 kw | |||||

Average Power Consumption (Take 60%Cutting Efficiency) | 126x60%=75.6 kw | 104x60%=62.4 kw | 104x60%=62.4 kw | |||||

All Cost (1RMB/kwh) | 75.6+5= 80.6 RMB/h | 62.4+40+5.0= 107.4 RMB/h | 624+150+5.0= 217.4 RMB/h | |||||