G-penny 5.5KW ER25 Stone Working Spindle Motor Water Cooling Gas Nozzle Bullet Type 380v / 220v 4pcs Ceramic Ball Bearings

US $407.18-415.48 / piece

1 piece(s)Minimum order

place of origin:

Jiangsu, China

weight (kg):

28

video outgoing-inspection:

Not Available

machinery test report:

Not Available

brand name:

G-penny Machine

application:

Milling

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Jiangsu, China |

|---|---|

| weight (kg) | 28 |

| video outgoing-inspection | Not Available |

| machinery test report | Not Available |

| brand name | G-penny Machine |

| application | Milling |

| maximum torque | 2.5N.m |

| drive | motor |

| operating speed | 0-24000rpm |

| warranty | 1 Year |

| core components | Bearing, motor |

| Size | 125x308.6mm |

| Power | 5.5kw |

| Frequency | 400HZ/800HZ |

| Voltage | 220V/380V |

| Current | 22A/15A |

| Collet | ER25 |

| Cooling | Water cooled |

| Lubrication | Grease |

| Phase | 3 |

| Bearing type | 2x7007C P4 DT and 2 x7205C P4 |

| Condition | New |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Showroom Location | Russia |

| Marketing Type | Ordinary Product |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

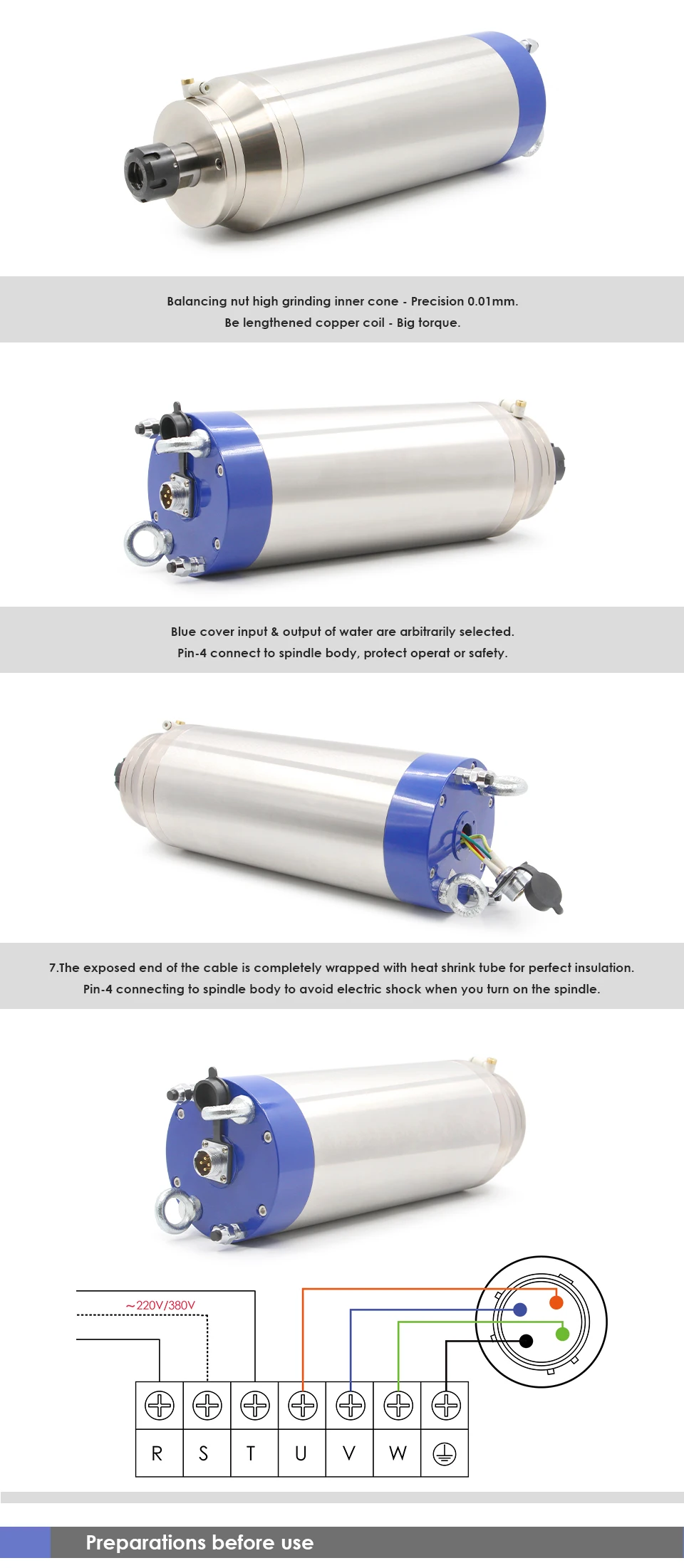

1 pcs & 220/380v AC 5.5kw ER25 Stone Working Water Cooled Spindle Motor Gas Nozzle Engraving Milling Grinding - 4pcs ceramic ball bearings

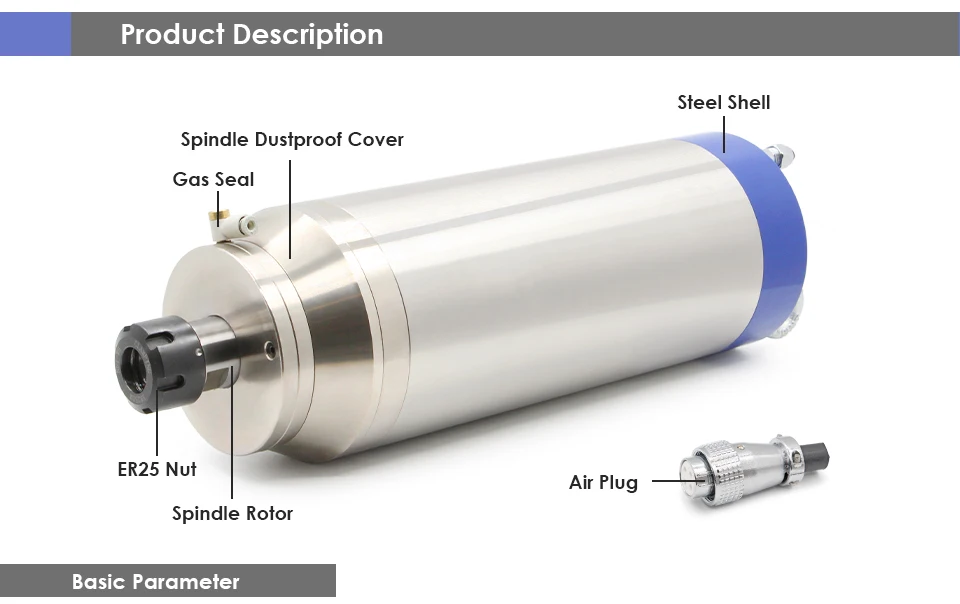

The spindle have gas nozzle, so you can connect it to air pump, and the the dust difficult go into spindle, good for stone working.

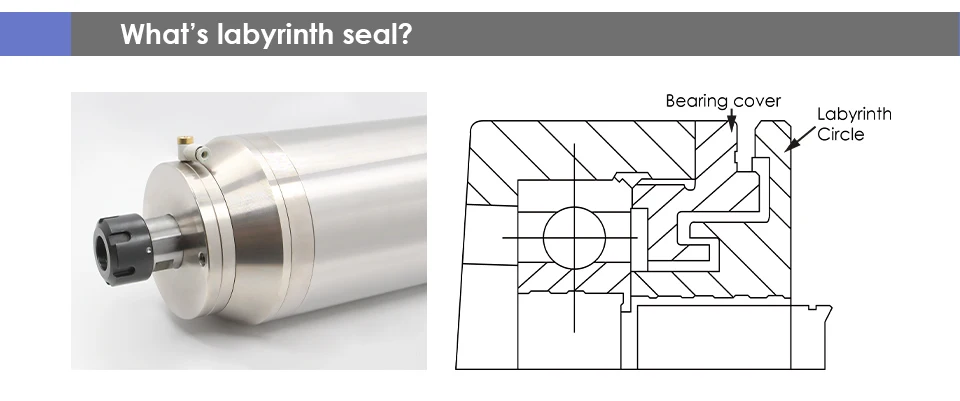

There are 4 labyrinth seal in the front section of the spindle,Prevents lubricant leakage from bearings and intrusion of harmful impurities (dust, moisture, corrosive gases) and bearing seals under high-speed conditions.

There are 4 labyrinth seal in the front section of the spindle,Prevents lubricant leakage from bearings and intrusion of harmful impurities (dust, moisture, corrosive gases) and bearing seals under high-speed conditions.

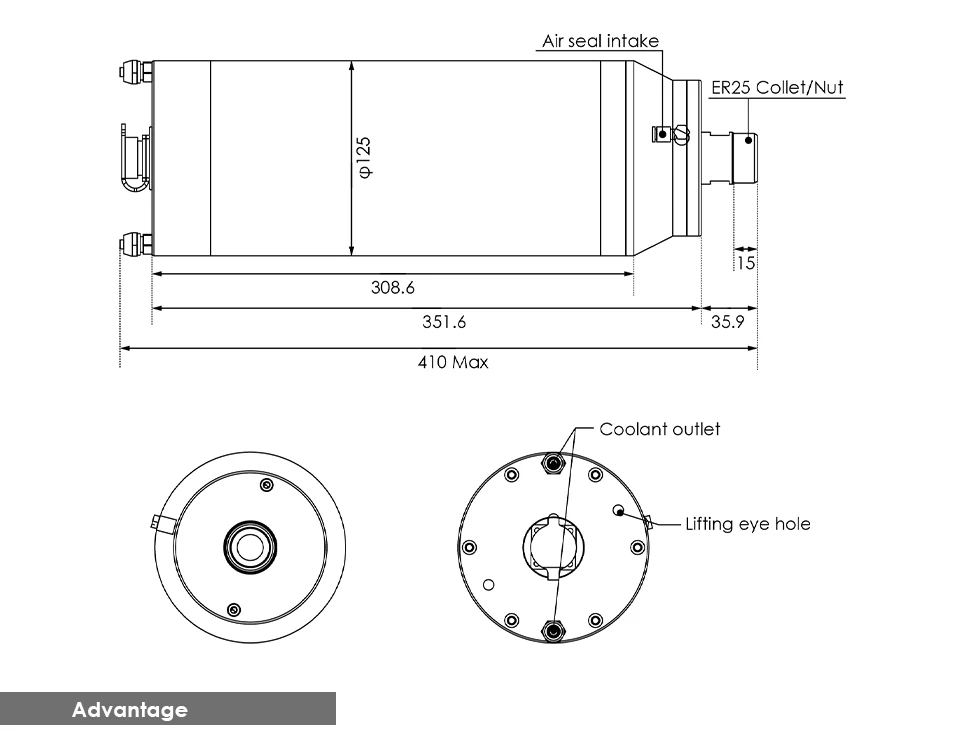

Size: 125x410mm (Middle body diameter:125mmxLength:308.6mm)

Material: 304 stainless steel jacket, iron shell,water jacket is pressure cast aluminum tubes, high temperature copper coil

Speed Ways: through the inverter output voltage and adjust the operating frequency can be achieved 0-24000 stepless

Cooling: water cooling mode

Power Interface: Optional KC20 waterproof air plug, there are marked 1234, 123 were connected to the inverter power supply (U, V, W), 4 connected inverter ground.

Power: 5.5KW

Voltage: 220v/380V

Current: 22A/15A

Frequency: 400Hz/800Hz

Speed: 12000-24000rpm

Runout Off: 0.01mm

Diameter(mm): 125

Bearing Type: 4 pcs ceramic ball bearings

Collet: ER25

Clip knifediameter: 1-20mm,3.175mm,6.35mm,12.7mm

Water Cooling ER25 collet chunk

Grease Lubrication

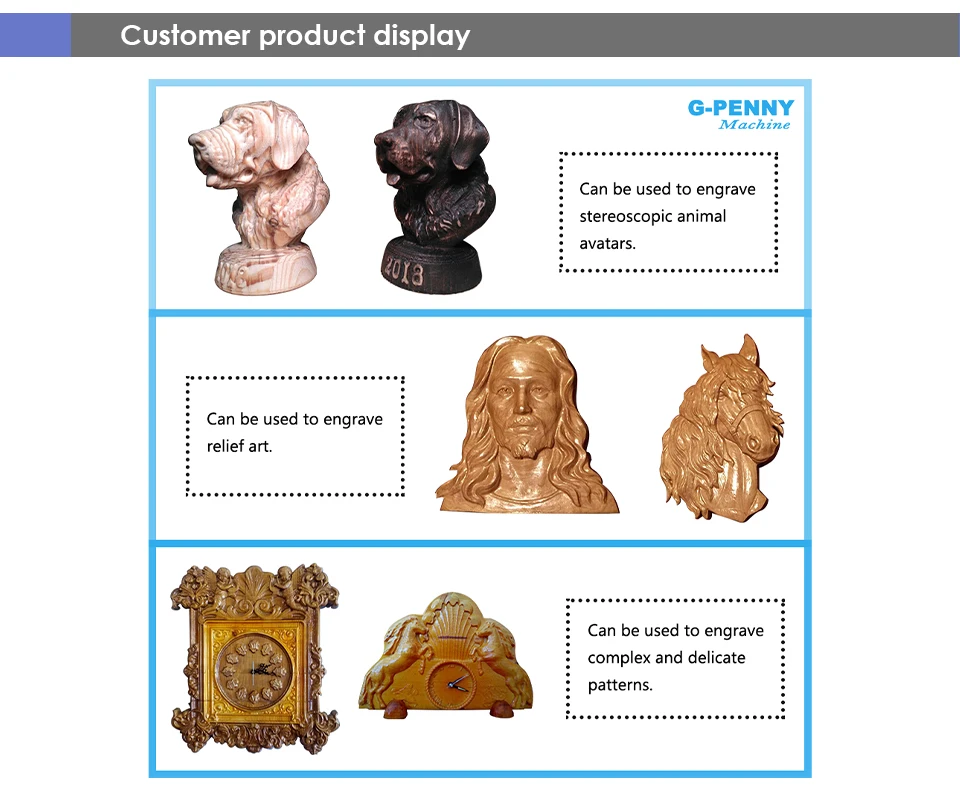

Main Application: Stone Working

Material: 304 stainless steel jacket, iron shell,water jacket is pressure cast aluminum tubes, high temperature copper coil

Speed Ways: through the inverter output voltage and adjust the operating frequency can be achieved 0-24000 stepless

Cooling: water cooling mode

Power Interface: Optional KC20 waterproof air plug, there are marked 1234, 123 were connected to the inverter power supply (U, V, W), 4 connected inverter ground.

Power: 5.5KW

Voltage: 220v/380V

Current: 22A/15A

Frequency: 400Hz/800Hz

Speed: 12000-24000rpm

Runout Off: 0.01mm

Diameter(mm): 125

Bearing Type: 4 pcs ceramic ball bearings

Collet: ER25

Clip knifediameter: 1-20mm,3.175mm,6.35mm,12.7mm

Water Cooling ER25 collet chunk

Grease Lubrication

Main Application: Stone Working

Size | Power | Voltage | Current |

125*308.6mm | 5.5KW | 220v/380v | 22A/15A |

Frequency | Speed | Diameter | Collet |

400Hz/800Hz | 12000-24000rpm | 125mm | ER25 |

● Unique design, the air nozzle can be connected to the air pump to prevent dust from entering the spindle, protect the bearing of the spindle, and improve the use time of the spindle.

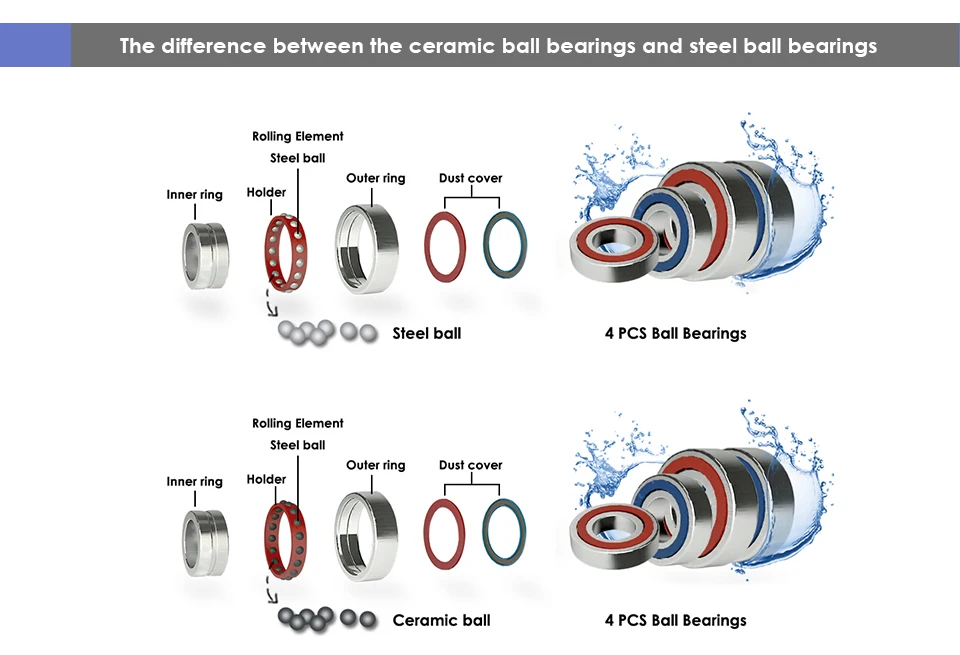

● 4 pcs ceramic ball bearing, extend the spindle using life.

● Iron casing, strong spindle rigidity, suitable for products with high hardness.

● High precision,runout off less than 0.01mm.Coaxial degree less than 0.0025mm.

● 4 pcs ceramic ball bearing, extend the spindle using life.

● Iron casing, strong spindle rigidity, suitable for products with high hardness.

● High precision,runout off less than 0.01mm.Coaxial degree less than 0.0025mm.

1. Our Ceramic ball bearings spindle use 4 pcs ceramic ball bearings.

2. Ceramic ball bearings are resistant to high temperatures and low heat, usually 3-5 degrees lower than steel ball bearings during using .

3. Ceramic ball bearings have low friction, low noise and long service life.

2. Ceramic ball bearings are resistant to high temperatures and low heat, usually 3-5 degrees lower than steel ball bearings during using .

3. Ceramic ball bearings have low friction, low noise and long service life.

● Spindle working environment temperature is usually -10 ~ 40 .

● Before installing the first electric spindle axis head turned by hand, should feel flexible, non-blocking phenomenon.

● Before installing the first electric spindle axis head turned by hand, should feel flexible, non-blocking phenomenon.

● Spindle in the preservation and transportation, high-speed grease inside the bearing state will change, customers should be running at low speed for 30 minutes. 3000 rpm and then follow the poor increase, run 20 minutes each. Spindle and the inverter should be working together. The inverter's specifications and parameter settings need match spindles parameter.

● Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

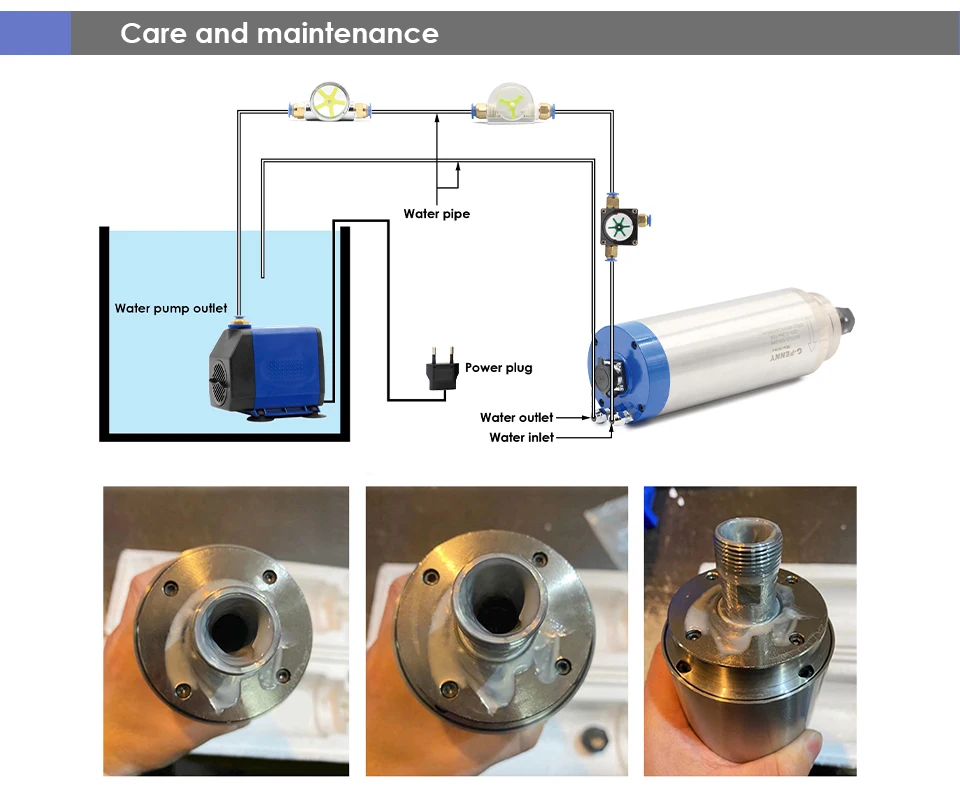

● It should ensure that before use of water-cooled spindle, the cooling system is working properly. Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts ,collets,cutters must be clean enough. Shank inserted into the collet must be greater than 15mm.

● Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

● It should ensure that before use of water-cooled spindle, the cooling system is working properly. Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts ,collets,cutters must be clean enough. Shank inserted into the collet must be greater than 15mm.

● Spindle run any unusual noise or vibration is particularly large, you should immediately stop check bearings. If it is necessary,the new bearings must be replaced. When running any unusual smells or sudden stop, immediately turn off the power, ground resistance measurements and three phase stator resistance, insulation resistance loss stator burned, should return to factory replacement stator with a shake table.

● Spindle grease should be changed regularly. To be replaced by trained service personnel.

Spindle shaft does not allow any mechanical braking force.

● Before shipping, we did the oil seal to avoid the rust during the long shipment. When you get the spindle, please clearing the oil seal before using. Thank you.

● If the spindle will not be used for a long time, please keep the spindle oil sealed to prevent rust from being unused for a long time.

● Spindle grease should be changed regularly. To be replaced by trained service personnel.

Spindle shaft does not allow any mechanical braking force.

● Before shipping, we did the oil seal to avoid the rust during the long shipment. When you get the spindle, please clearing the oil seal before using. Thank you.

● If the spindle will not be used for a long time, please keep the spindle oil sealed to prevent rust from being unused for a long time.

1. Cooling in different ways: water-cooled spindle motor is the use of the water cycle to cool the heat generated after the high-speed rotating spindle, spindle motor with fan-cooled approach to cooling.

2. Noise: Water-cooled spindle motor is basically no noise, but the air-cooled spindle motor is very loud.

3. Life aspects: Water-cooled spindle motor pay attention to maintenance, frequently changes the water or the use of industrial water coolers, air-cooled spindle fan mainly by the wind blowing the heat transferred to the heat sink, so as to achieve the cooling effect.

2. Noise: Water-cooled spindle motor is basically no noise, but the air-cooled spindle motor is very loud.

3. Life aspects: Water-cooled spindle motor pay attention to maintenance, frequently changes the water or the use of industrial water coolers, air-cooled spindle fan mainly by the wind blowing the heat transferred to the heat sink, so as to achieve the cooling effect.

Spindle from the production - assembly - test, and finally the perfect packaging .

We will 100% guarantee security to the hands of the guests.

We will 100% guarantee security to the hands of the guests.

Shipping Cost

Our products are sold worldwide.

If you need many items in the same time, please contact us in advance to confirm shipping cost.

Payment:

We accept paypal credit, bank transfer, western union etc.

Payment must be made within 7days calendar days of the auction end time.

Problem and Feedback:

PLEASE DON'T leave any negative feedback before you contact us.

We are honest and helpful supplier , we will try our best to solve problems with you.

Your satisfaction is very important for our store, so please contact us before you want to leave a negative feedback.

Thanks very much in advance.

Refund:

If you are NOT SATISFIED with our package like the products is damage, please do not sign it and contact us immediately.

If it is possible, please take some photos or make a small video about it. It will help us to solve the problems.

Note:

We can produce the product according to our customer's design.

If you need something is very special, please contact us about it.

We are willing to help you about it.

Our products are sold worldwide.

If you need many items in the same time, please contact us in advance to confirm shipping cost.

Payment:

We accept paypal credit, bank transfer, western union etc.

Payment must be made within 7days calendar days of the auction end time.

Problem and Feedback:

PLEASE DON'T leave any negative feedback before you contact us.

We are honest and helpful supplier , we will try our best to solve problems with you.

Your satisfaction is very important for our store, so please contact us before you want to leave a negative feedback.

Thanks very much in advance.

Refund:

If you are NOT SATISFIED with our package like the products is damage, please do not sign it and contact us immediately.

If it is possible, please take some photos or make a small video about it. It will help us to solve the problems.

Note:

We can produce the product according to our customer's design.

If you need something is very special, please contact us about it.

We are willing to help you about it.