Gcld Type Giicl Curved Tooth Spline Steel Motor Shaft Planetary Rexnord Sleeve Elastomer Drum Rigid Gear Coupling

US $35.00-45.00 / piece

50 piece(s)Minimum order

Warranty:

3 years

Applicable Industries:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Retail, Energy & Mining, Construction works

Customized support:

OEM, ODM, OBM

Structure:

Gear

Flexible or Rigid:

Rigid

Standard or Nonstandard:

Standard

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Warranty | 3 years |

|---|---|

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Retail, Energy & Mining, Construction works |

| Customized support | OEM, ODM, OBM |

| Structure | Gear |

| Flexible or Rigid | Rigid |

| Standard or Nonstandard | Standard |

| Material | Steel |

| Brand Name | EVER-POWER |

| Place of Origin | Zhejiang, China |

| Color | Custom Requirement |

| Body Material | Stainless Steel Aluminum Steel |

| Application | Industrial Equipment |

| Certification | ISO9001:2008 |

| Packing | Poly Bag + Inner Box + Carton |

| Service | OEM .ODM .Customized |

| Outer diameter | 14-120mm |

Product Detail

Products Description

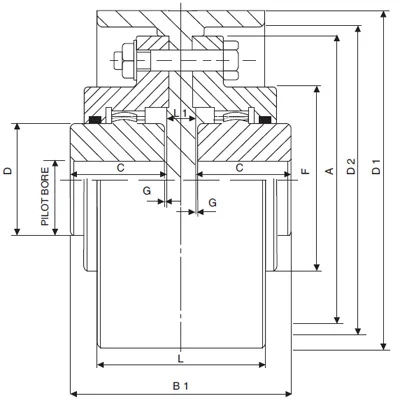

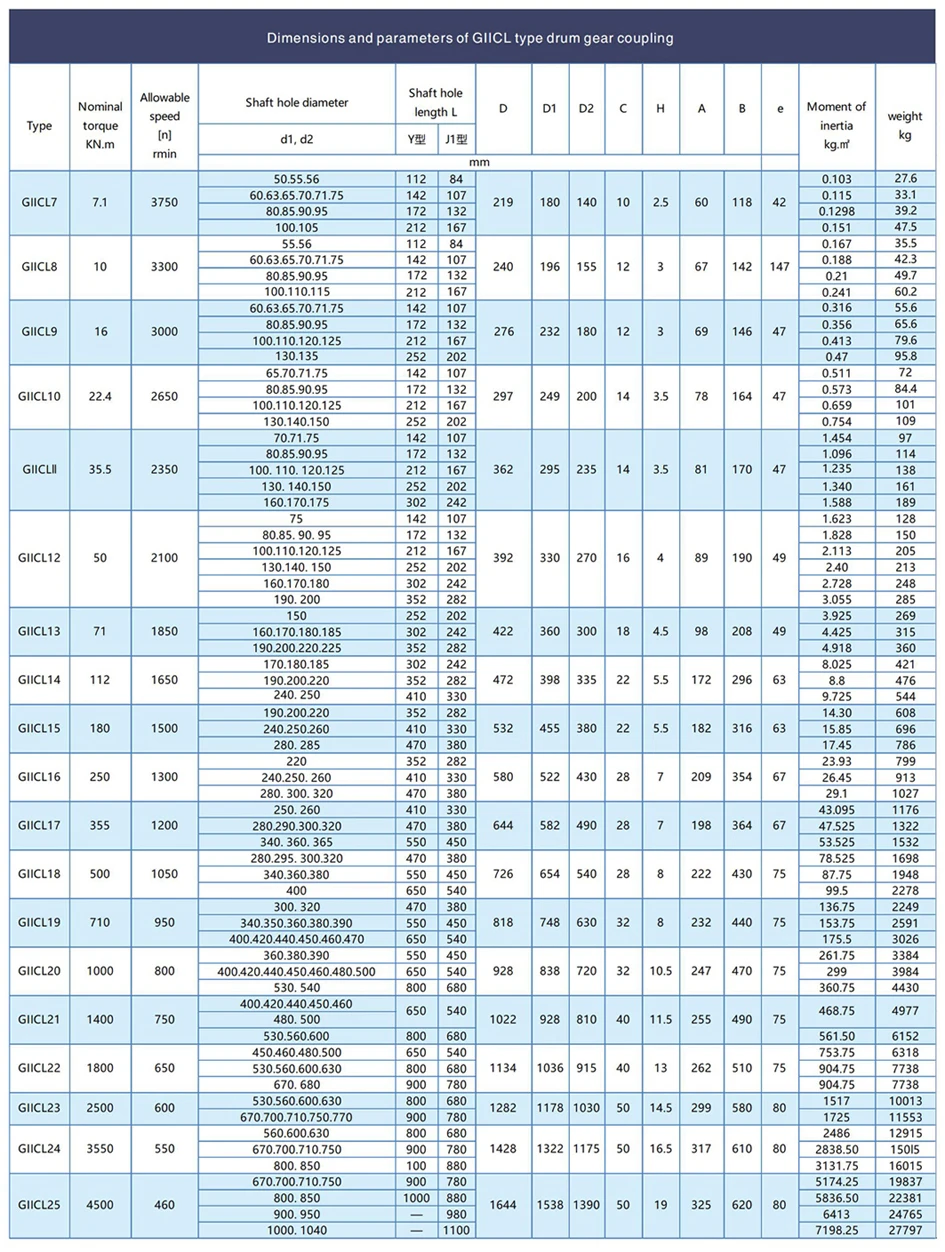

Drum gear couplings are flexible couplings with axes compensation capabilities between the radial, axial, and angular.Compared with CL straight gear couplings, they have a compact structure, a small turning radius, and more Large capacity, high transmission efficiency, low noise and long maintenance cycle. GICL, GICCL series drum gear coupling, especially suitable for low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries, but also suitable for petroleum, chemical, general machinery and other machinery shaft drive Characteristics of drum gear coupling (compared with straight gear coupling)

1.Strong bearing capacity. If outer diameter of the inner sleeve equals outer diameter of the coupling, the bearing capacity of the drum gear coupling is 15 to 20% higher than that of the straight gear coupling on average ;

2. Large amount of angular displacement compensation.Drum gear couplings can allow larger angular displacements (relative to straight gear couplings), which can improve the interface conditions of the gear, improve the ability of transmit torque, and extend the service life.

3 The drum-shaped gear surface improves the interface conditions of the internal and external gear,, avoids the disadvantages of the straight gear end edge squeezing and stress concentration under the angular displacement condition, improves the gear surface friction conditions and reduces noise , long maintenance intervals;

4. The gear end of the outer gear sleeve is in the shape of a trumpet, which makes dismounting very convenient.

5 Transmission efficiency is as high as 99.7%. Based on the above characteristics, straight gear couplings have been generally replaced by drum gear coupling at home and abroad.

6 Drum gear couplings have the advantages of small size, large transmission torque, strong ability to absorb inaccuracy and excellent durability. They are the most commonly components for two drive shafts in medium and heavy machinery. The drum gear coupling needs to work in a good and sealed state.

Material | Cast iron, Rubber |

process | Machined, Forged |

Heat treatment | High frequency quenching heat treatment, hardened teeth |

Surface treatment | color painting, or customer requirement |

Performance | High precision, high wear resistance, low noise, smooth and steady, high strength |

Model number | NM50,NM67, NM82, NM97, NM12, NM128, NM148,NM168, NM194, NM214 |

Payment,minimum order and delivery | T/T ,LC, Delivery time is Negotiation |

Packaging | Carton box or customer requirement. |

Related Products

Click the following picture to learn more

Company Information

EVER-POWER GROUP SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, ARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACUUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Product packaging

Contact Us