Good Quality Dolomite ultra Fine Vertical Powder Grinding Mill for Dolomite Powder Production Line

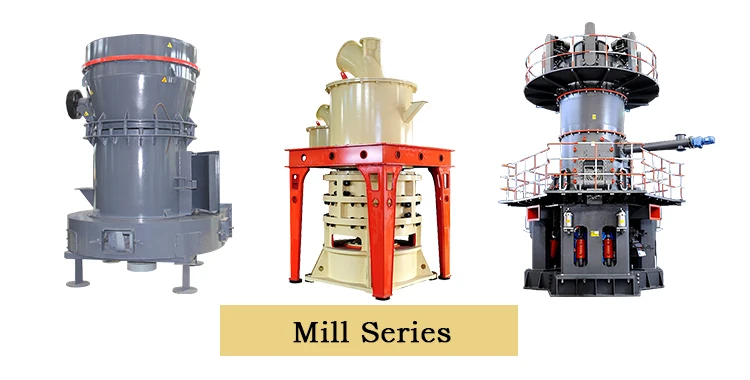

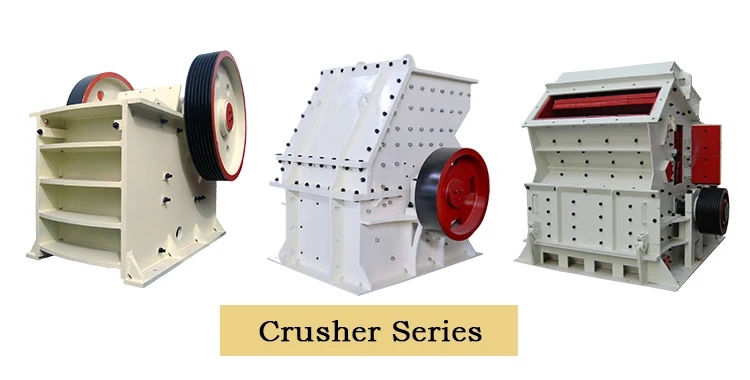

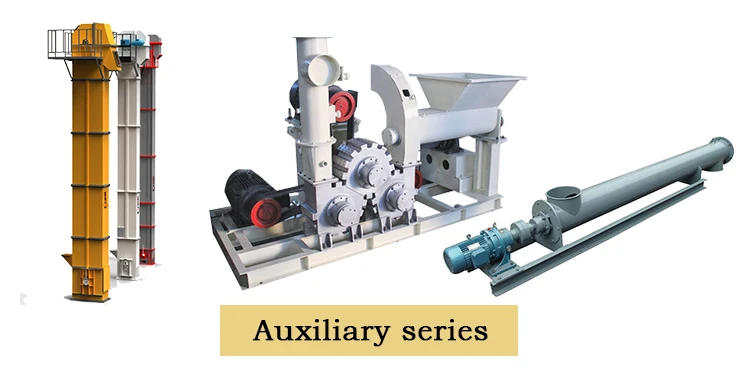

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Pressure vessel |

| Type | Vertical Roller Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 10-300TPH |

| Place of Origin | Shanghai, China |

| Brand Name | Clirik |

| Dimension(L*W*H) | M) Dimension |

| Weight | 17.8 KG |

| Warranty | 2 Years |

| Application | Stone Powder Grinding |

| Name | Micro Powder Vertical Mill |

| The Machines classification | Granding Mill Machine |

| Color | Customerized |

| Product name | Vertical Mill |

| Installation | Engineer's Guide |

| Spare parts supplying | Life Long Provide |

| After sale service | Warrantly |

| Feeding size | Equal |

| Output size | Changeable |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

Application of calcium carbonate powder Pulverizer Vertical Roller Mill Machine

Vertical roller mill are suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 9.3(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Working Principle of calcium carbonate powder Pulverizer Vertical Roller Mill Machine

Advantages of calcium carbonate powder Pulverizer Vertical Roller Mill Machine

1. High grinding efficiency: save 20~30% power consumption compared with the ball mill. With the increasing of moisture content, it can save more and more electricity.

2. Strong drying capacity: dry and grind raw materials with moisture content as much as 15%.

|

Main configuration and production |

|||

|

Model Item |

CLUM1425 |

CLUM1632 |

CLUM1736 |

|

Working Diameters(mm) |

1400 |

1600 |

1700 |

|

Number of rollers(pieces) |

3 |

3 |

3 |

|

Number of classifier(pieces) |

5 |

7 |

7 |

|

Power of classifier(Kw) |

5X15 |

7X15 |

7X(15~18.5) |

|

Main unit power (Kw) |

250 |

315 |

355 |

|

Blower power(Kw) |

200 |

250 |

315 |

|

Feed size (mm) |

<10mm |

<10mm |

<10mm |

|

Moisture of feeding material |

<3% |

<3% |

<3% |

|

Less than 2μm=34% output(t/h) |

11-14 |

13-17 |

15-19 |

|

Less than 2μm=46% output(t/h) |

7-8 |

9-10 |

11-12 |

|

Less than 2μm=60% output(t/h) |

3-4 |

/ |

/ |

|

Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

Our Certification

Our Company

Packing&Shipping

|

|

|

|

|

Services For You:

1.one year guarantee for whole machine except for wear parts;

2.24 hours technical support by email;

3.calling service;

4.user manual available;

5.reminding for the service life of the wearing parts;

6.installation guide for clients from both China and abroad;

7.maintance and replacement service;

8.whole process trainling and guidance from our technicians.

High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

FAQ

Q: Are your vertical roller mill can procee the slag and other hard materials?

A: Our grinding parts of the vertical roller mill are made by hard materials, so it can be used in slag, cement and other hard materials grinding.

Q: What the fineness range of the vertical roller mill?

A: It can be adjusted between 300 mesh to 4000 mesh.

Q: Are you a manufacturer or middleman?

A: Our Shanghai Clirik is a professional vertical roller mill manufacturer.

More Information Welcome to Leave Your Message to Inquiry.

Shanghai Clirik Machinery Co. Ltd., devoted into the mining equipment R&D and manufacturing more than decades years

If You Are Interested in Our Mining Equipment

Welcome to contact us

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai, China.

We are looking forward to cooperate with you

| Micro Powder Grinding Mill | Coating Machine | High Pressure Suspension Grinding Mill |

|

|

|

|

Finished Size: 300-2500(mesh)Capacity: 0.5-45(t/h) Pass rate: D97 5 micron |

Used to stone powder modification machine

|

Finished Size: 50-450(mesh)Capacity: 1-28(t/h) Pass rate: D90 30 micron |