HDPE Plastic Bottle Making Blow Moulding Machine

Other recommendations for your business

Contact us

Quik Detail

| video outgoing-inspection | Provided |

|---|---|

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, Pump |

| plastic processed | PP, HDPE, PE, PE/PP, HDPE/PP |

| place of origin | Zhejiang, China |

| brand name | JUNENG |

| voltage | 220V/380V/3phase |

| dimension(l*w*h) | 4.5*3.3*2.8 |

| clamping force (kn) | 160 |

| plc brand | Siemens |

| screw l/d ratio | 25 |

| screw diameter (mm) | 90 mm |

| output (kg/h) | 200 kg/h |

| automation | Automatic |

| No. of Screw Heating Zone | 4 |

| screw heating power(kw) | 6.8 kW |

| extruder motor power(kw) | 150 kW |

| mold platen size(width)(mm) | 550 mm |

| mold platen size(height)(mm) | 500 mm |

| air pressure(mpa) | 0.6 MPa |

| air comsumption(m³/min) | 0.8 m³/min |

| die head heating power(kw) | 5.3 kW |

| power (kw) | 37 |

| weight (t) | 12 |

| key selling points | Easy to Operate |

| warranty | one year |

| Blow Moulding Type | Extrusion Blow Moulding |

| Automatic | Yes |

| After-sales Service Provided | Engineers available to service machinery overseas |

| low-voltage apparatus | SCHNEIDER |

| electrical motor | SIEMENS.BEIDE |

| air valve | TANWAN AIRTAC |

| keyword | extrusion molding machine |

| Weight | 12ton |

| Certification | ISO9001 |

| Power | 30KW |

| Condition | New |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Application | Bottle |

| Applicable Industries | Food & Beverage Factory, Advertising Company |

| Showroom Location | None |

| Year | 2021 |

| Accumulator Capacity(L) | 3 L |

Product Detail

HDPE plastic bottle making blow moulding machine

Do the best for customers!

Workshop:

Mould workshop:

Sample room:

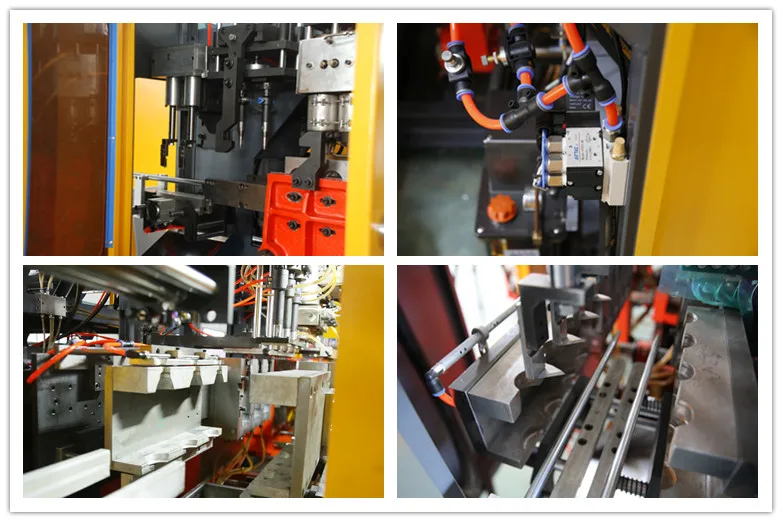

Juneng machine specially designed toogle balanced mold locking mechanism.Using the high-pressure die locking,force bearing point is settled on the upper side of the center of mould plate.This high clamping force ensures the uniformity of the stress.Applying Servo valve Position transducer which shortens empty circle time,increases the output,lowers energy consumption and improve the stability.

Machine general specification:

| Extrusion Blow Moulding machine | |

| Model | JNT-90U |

| Material | PE/PP |

| Max product volume (L) | 12L/1;5L/2 |

|

Dry cycle (pc/hr) |

600*2 |

| Screw diamter (mm) | 90 |

| Screw L/D ratio (L/D) | 24-26 |

| Screw motor power (KW) | 37 |

| Screw heating capacity (kw) | 6.8 |

| No.of heating zone (zone) | 4 |

| Output of HDPE (kg/hr) | 120-140 |

| Oil pump driver power (kw) |

22 |

| Clamping force (KN) | 160 |

| Mold stroke (mm) | 240-600 |

| Size of mold w*h (mm) | 550*500 |

| Moving distance (mm) | 600 |

| Max die diamter w*h (mm) | 220 |

| Die heat capacity (kw) | 3.5-5.3 |

| Blowing pressure (mpa) | 0.6-0.8 |

| Air volume (m3/min) | 0.8 |

| Cooling water pressure (mpa) | 0.5 |

| Water consumption (L/min) | 70 |

| Weight of machine (ton) | 12 |

| Size of machine (m) | 4.5*3.3*2.8 |

Machine details:

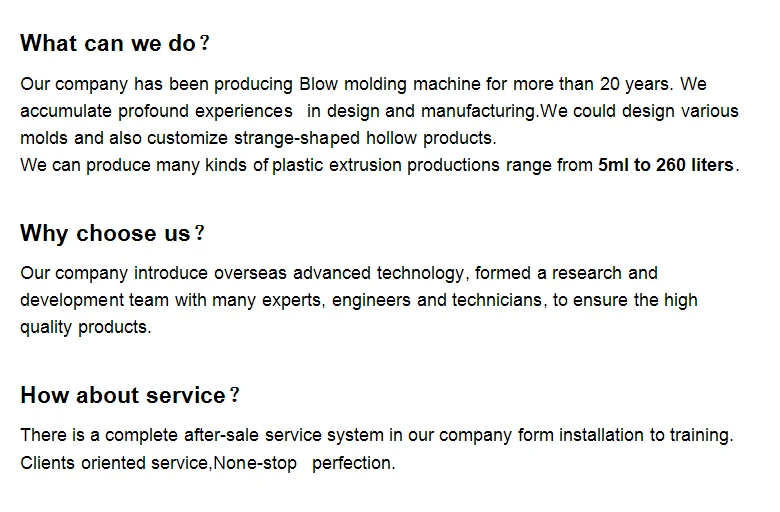

1--PLC,touch screen,screw and die head

2--Blowing part(blow pin & blowing valve),deflashing

3--MOTOR & MAIN VALVE

we will do the best for customer!!!

JUNENG has cultivated a strong team to provide prompt and effective after sale service,helping the customers tuo solve problems appeared during the machine commissioning and production. We also record service history for each customer to privide quicker and more accurate service subuequently. Our target is to statisfy the customer by 100%.

1.PACKING: STANDARD EXPORT PACKING

2.DELIVERY:60 DAYS AFTER CONFIRM THE PRODUCTS DRAWINGS.

All the equipments, moulds(except the blowing moulds) and auxiliaries supplied by our company, we will provide all of the techniques and technology, and supply free install and adjusting operation, ensure the technology reliability and rationality.

You have two choices,One is your technical people come to our company, we teach your person how to operate the machine, how to maintain it and so on, but all of the cost should be paid by yourself.

Two is we supply engineer to you, you provide the cost of the visa, passenger tickets(round-trip ticket), room and board. Beside you need pay our person 100USD per day, and also we will pay our person. The place is supplied by yourself.