High Efficiency Ten-Axis BOPP PVC Tape Slitting Cutting Machine New Adhesive Rewinder for Retail Industries Panasoni PLC Motor

1 set(s)Minimum order

type:

Slitting Rewinder

computerized:

Yes

place of origin:

Jiangsu, China

brand name:

Hexin

voltage:

220

dimension(l*w*h):

3300*1800*2000mm

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| type | Slitting Rewinder |

|---|---|

| computerized | Yes |

| place of origin | Jiangsu, China |

| brand name | Hexin |

| voltage | 220 |

| dimension(l*w*h) | 3300*1800*2000mm |

| warranty | 1 Year |

| production capacity | 100 m/min |

| key selling points | high efficiency |

| Working Width | 1300mm |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, PLC |

| plc brand | Panasonic |

| Weight (KG) | 2500 |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Maximum width of mother roll | 1300mm |

| Inner diameter of paper core | 76mm(25-76mm is available for customized) |

| slitting accurancy | 0.1mm |

| Power | 9.5KW |

| Slitting width | 2-1300mm |

| Round knife | 160mm double edge |

| Maximum cutting diameter | 150mm |

| Voltage | 380V or customized |

Product Detail

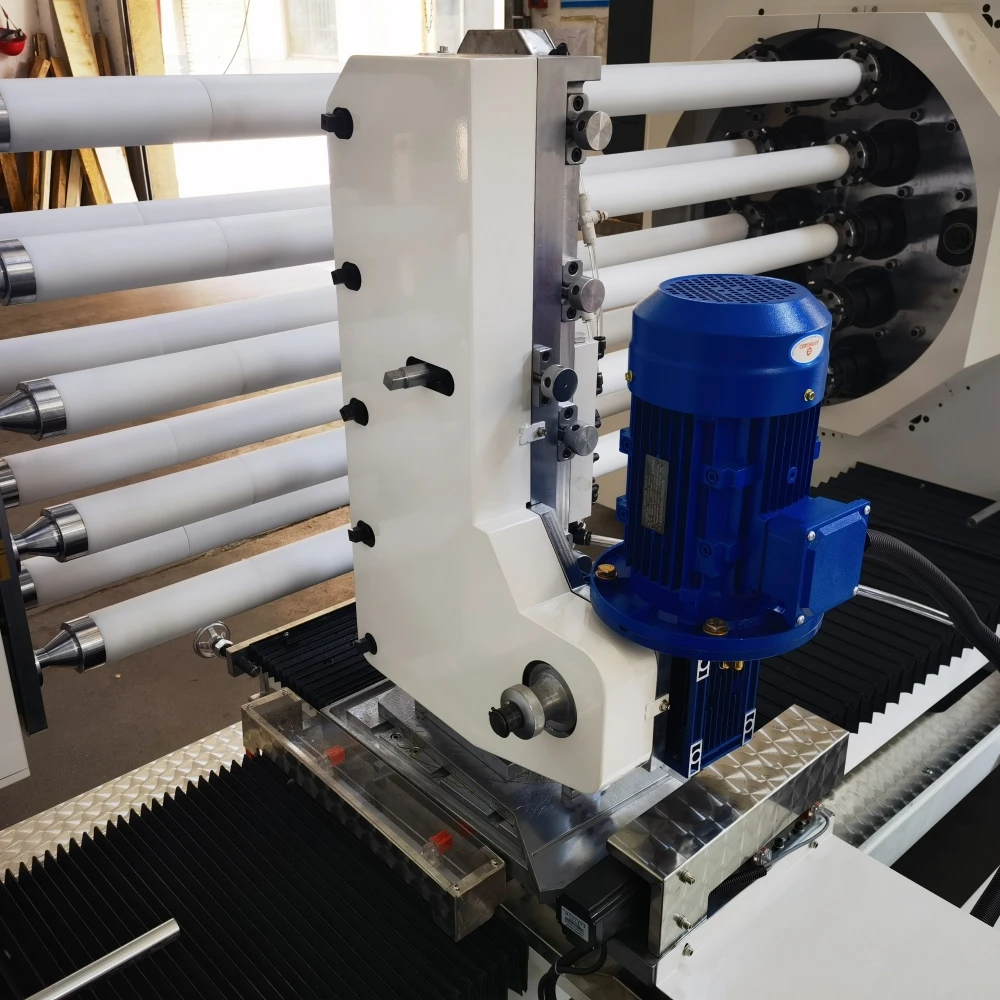

High efficiency Ten-axis adhesive bopp pvc tape roll tape slitter cutting machine

Product Description

Sizing cutting for conductive fabric,foam,reflector film,double-sided adhesive tape,nickel plate,PET,PC,PE insulation paper ,copper/aluminum foil and all kinds of adhesive tapes.

Sample

Feature

Cutting Material Width | 1300mm | Cutting Width | 1mm~1300mm | |

Inner Dia.of Cutting core | 3"(25mm~76mm Customized) | Cutting Accuracy | ± 0.1mm | |

Cutting Max.Dia. | 150mm | Dimension | 3200mm*1800mm*2000mm | |

Maximum Cutter Dia. | 160mm | N.Weight | 2800 KGS | |

Voltage | 380V 50HZ(Customized available 220V) | Power | 9.5KW |

Characteristics

No. | Host Configuration | Configuration Specification | Quantity |

1 | Bearing | Machine Bearing NSK from Japan | 1 set |

2 | Low Voltage Protection | Leakage protection switch | 1 set |

AC contactor | 1 set | ||

Switching Mode Power Supply | 1 set | ||

Electric Relay | 1 set | ||

3 | Function of Electric Cooker | 6 Cutting Scenarios One-click Conversion | 1 set |

4 | Host Setting Device | 10"Flip Type Touch Screen | 1 set |

5 | Control System | 12 Mode Settings (Open End),Intelligent three-segment speed control | 1 set |

6 | PLC | Programming Controller + Extension Module | 1 set |

7 | Main Orientation of Cutter | C5 Grade Precision ball screw drive | 1 Group |

8 | Cross main feed positioning | C5 Grade Precision ball screw drive | 1 Group |

9 | Trailer Sliding | Straight Line Slide | 2 Groups |

10 | Control Handle | Cross-switch | 3 pcs |

11 | Photoelectric Switch | Photoelectric Switch | 6 pcs |

12 | Main spindle motor inverter | 7.5P Variable Frequency Converter | 1 Group |

13 | Blade motor inverter | 5.5P Variable Frequency Converter | 1 Group |

14 | Transverse positioning of cutter | 1000W Servo Motor Driver | 1 set |

15 | Blade feed drive | 1000W Servo Motor Driver | 1 set |

16 | Flip Positioning | 1000W Servo Motor Driver ( Expanding 50:1 High-torque Output ) | 1 set |

17 | Cutting Blade Electric Motor | 380V 50HZ 3P-4H a-c dynamo | 1 set |

18 | Main Shaft Motor | 380V 50HZ 5.5P-6H a-c dynamo | 1 set |

19 | Sheet Metal Paint | Imported powder spray paint | 1 set |

20 | Lighting System | 24v LED Lighting | 1 set |

21 | Refrigerating System | 90W No drip leakage in water pump | 1 Group |

22 | Tail bracket | Magnetic cylinder | 1 set |

23 | Triple combination | Lilter water vapor and regulate air pressure | 1 Group |

24 | Cutting Shaft | Diameter 76 mm Cutting Shaft | 10pcs |

25 | Swing angle system | Step Auto Swing Angle | 1 set |

26 | Clamping Device | Pneumatic piston automatic claw | 10 sets |

27 | Feed Hopper | Stainless Steel Hopper | 1 set |

28 | Round Blade | 160mm Double-edged Blade | 5 pcs |

29 | Random Accessories | Cut Sleeve PE Tube | 10 pcs |

30 | Service Tools | General Maintenance Tools | 1 set |

31 | Clip Cutter | Dia.70 mm | 5 sets |

Related Products

Company Introduction

;We are a team of industry professionals with strong backgrounds in cutting, die cutting,

slitting, laminating and rolling. Other related machines in our fields can be customized based on your specific requirements.

Kunshan Hexin Precise Machinery Co.ltd is located in Kunshan city,Jiangsu province. We are near Shanghai,40 minutes away from Shanghai Hongqiao airport by car and 18 minutes by high speed train.

Established in 2007, we have been dedicated on converting machines which are used before and after printing for over 10 years.

Our belief is “people-oriented, technology-first, integrity-centered and brand idea” to provide customers reliable products,

perfect service.Our products are widely applied in laminating, slitting and die cutting for shield materials, sticky materials,

insulating materials, conductive materials, electronic materials. Sizing cutting for strings, belts, rolls in bag line, shoe and

cap line and plastic and rubber line.

slitting, laminating and rolling. Other related machines in our fields can be customized based on your specific requirements.

Kunshan Hexin Precise Machinery Co.ltd is located in Kunshan city,Jiangsu province. We are near Shanghai,40 minutes away from Shanghai Hongqiao airport by car and 18 minutes by high speed train.

Established in 2007, we have been dedicated on converting machines which are used before and after printing for over 10 years.

Our belief is “people-oriented, technology-first, integrity-centered and brand idea” to provide customers reliable products,

perfect service.Our products are widely applied in laminating, slitting and die cutting for shield materials, sticky materials,

insulating materials, conductive materials, electronic materials. Sizing cutting for strings, belts, rolls in bag line, shoe and

cap line and plastic and rubber line.

Certifications

Our company