High Quality Chrome Ore Processing Plant Milling Equipment 30 Tons Continuous Grid Type Gold Mining Stone Grinding Wet Ball Mill

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Bearing, motor

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

8-35

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Bearing, motor |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 8-35 |

| Place of Origin | Guangdong, China |

| Brand Name | Fetech mining |

| Dimension(L*W*H) | 10187x4685x3720 |

| Weight | 5360 KG |

| Warranty | 1 Year |

| Product name | Overflow ball mill |

| Model | customization |

| Applicaton | Mining Quarry Stone Crushing Plant |

| Advantage | Long Lifework |

| Factory Visit | Warmly Welcomed |

| Installation | Under Engineer's Guide |

| Applicable Industries | Building Material Shops |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

Products Description

Details

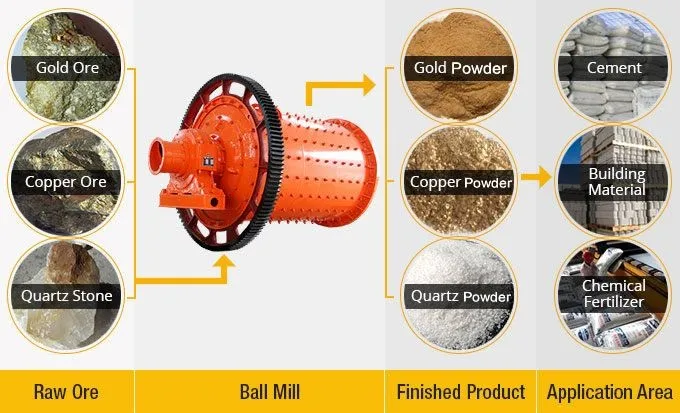

Overflow ball mill is a kind of ball grinding mill which works in wet water state. It belongs to a type of wet ball mill and is a

very common grinding equipment in the concentrator. Ball grinding mills are classified according to the discharge methods and can

be divided into overflow ball mill and grate ball mill. Unlike the grate ball mill, the overflow type ball mill has a simple

structure, and the discharge method is based on the gravity flow of the slurry to discharge the ore.

very common grinding equipment in the concentrator. Ball grinding mills are classified according to the discharge methods and can

be divided into overflow ball mill and grate ball mill. Unlike the grate ball mill, the overflow type ball mill has a simple

structure, and the discharge method is based on the gravity flow of the slurry to discharge the ore.

Model | Cylinder RPM (r/min) | Ball load (t) | Feeding size (mm) | Discharging size (mm) | Capacity(t/h) | Motor | Dimension (mm) | Welght (t) | ||||||||||

Model | Power | |||||||||||||||||

600x1800 | 45.5 | 0.5 | ≤10 | 0.074-0.5 | 0.2-0.5 | Y160M-6 | 7.5 | 3100x1624x1070 | 2.5 | |||||||||

900x1800 | 38 | 1.8 | ≤ 20 | 0.074-0.6 | 06-2 | Y180L-6 | 15 | 4196x2300x1985 | 5.8 | |||||||||

900x3000 | 37.4 | 2.7 | ≤ 20 | 0.074-0.3 | 0.8-3 | Y200L2-6 | 22 | 6170x2034x2074 | 7.5 | |||||||||

1200x2400 | 32 | 4.8 | ≤25 | 0.074-0.6 | 1.5-4 | Y225M-6 | 30 | 6520x2850x2540 | 9.8 | |||||||||

1200x4500 | 30 | S.2 | ≤25 | 0.074-0.6 | 1.5-6 | Y2805-6 | 45 | 8820x3070x2630 | 13.2 | |||||||||

1300x4000 | 36 | 5.8 | ≤25 | 0.074-0.6 | 2-6 | Y280S-8 | 45 | 7661x2720x2100 | 14.8 | |||||||||

1500x3500 | 28.8 | 8.3 | ≤25 | 0.074-0.6 | 3-6 | YR280M-8 | 90 | 8500x3100x2100 | 17.6 | |||||||||

1500x4500 | 2B.8 | 10 | ≤25 | 0.074-0.4 | 4-8 | JR125-8 | 95 | 9680x3200x2114 | 22.3 | |||||||||

1500x5700 | 28.8 | 12 | ≤25 | 0.074-0.4 | 5—10 | JR126—8 | 110 | 10440x3200x2114 | 26.7 | |||||||||

1500x6400 | 28.8 | 13 | ≤25 | 0.074-0.4 | 8—12 | JR127-8 | 130 | 11140x 3200x2114 | 29.2 | |||||||||

1830x3600 | 24.5 | 12 | ≤25 | 0.074-0.4 | 5-10 | JR127-8 | 130 | 7880x4000x3370 | 31.4 | |||||||||

1830x5400 | 24.5 | 15 | ≤25 | 0.074-0.4 | 5-20 | JR137-8 | 210 | 9800x4685x3750 | 33.6 | |||||||||

1830x6400 | 24.S | 19 | ≤25 | 0.074-0.4 | 6-25 | JR137-8 | 210 | 11710x4685 x3750 | 36.5 | |||||||||

1830x7000 | 24.5 | 20 | ≤25 | 0.074-0.4 | 8-30 | JR138-8 | 245 | 12320x4685x3750 | 39.6 | |||||||||

2100x3600 | 24.1 | 21 | ≤25 | 0.074-0.6 | 8-20 | YR355L1-8 | 210 | 9016x4510x3720 | 43.2 | |||||||||

2100x4500 | 24.57 | 26 | ≤25 | 0.074-0.6 | B-35 | JR138-8 | 280 | 10187x46B5x3720 | 53.6 | |||||||||

Can Customized According Actual Needs | ||||||||||||||||||

Company Profile

Company Profile: Future Explorer Technical Eqiupment Co.,Ltd (FETECH)

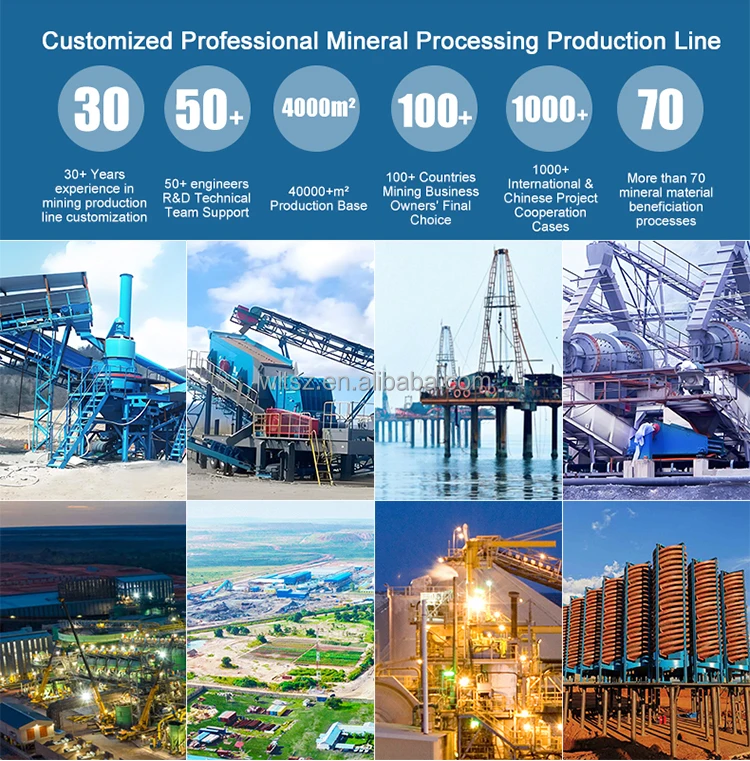

Future Explorer Technical Eqiupment Co.,Ltd was founded in 2015. It is a mining service organization specializing in mining machinery manufacturing, mineral analysis, and mineral processing equipment design, installation and commissioning.

For more than 20 years, we have focused on the R&D, design and production of mining mineral processing equipment. The core founding team has independently designed and developed customized production line one-stop solutions for mining projects in 100+ countries around the world based on customer needs and the local geographical environment of the mine. Including on-site survey, product design, manufacturing, installation, commissioning and after-sales service. In addition,We also maintain long-term cooperation with international and Chinese scientific research institutions of universities to explore new and efficient technologies, improving economic efficiency while protecting the environment

Our products sell well all over the world:

1. Oceania: Australia, New Zealand

2Africa: South Africa, Sudan, Zimbabwe, Ghana, Tanzania, Uganda, Congo, Zambia, Nigeria,

3 Americas: United States, Canada, Brazil, Mexico

4Europe: Romania,

5 Asia: South Korea, India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan, Kyrgyzstan, Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

30+Years experience in mining production line customization

50+engineers R&D Technical Team Support

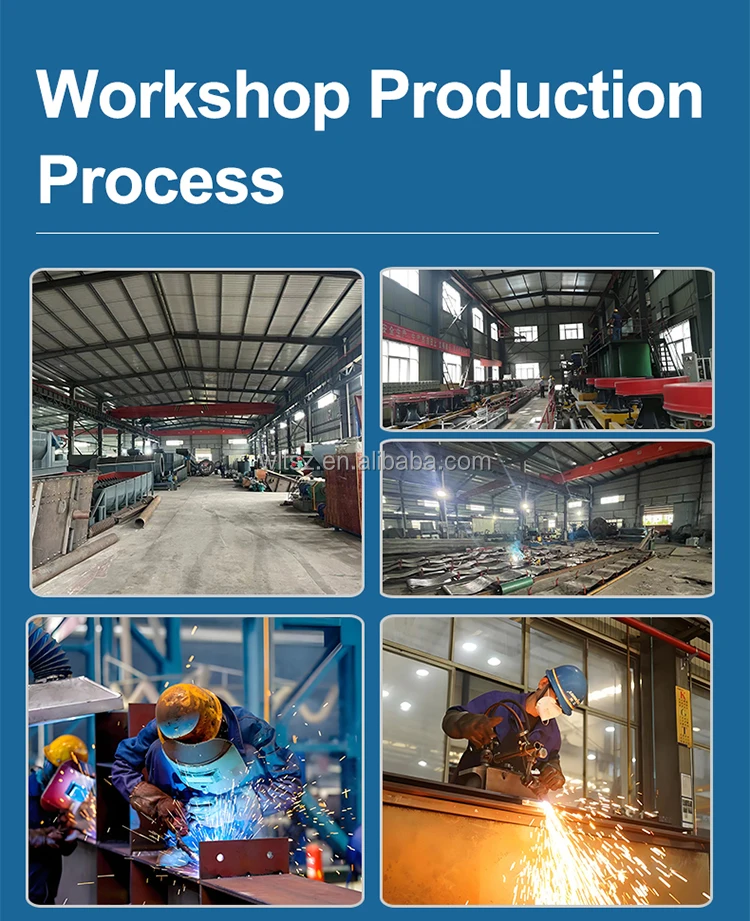

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

We support EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )

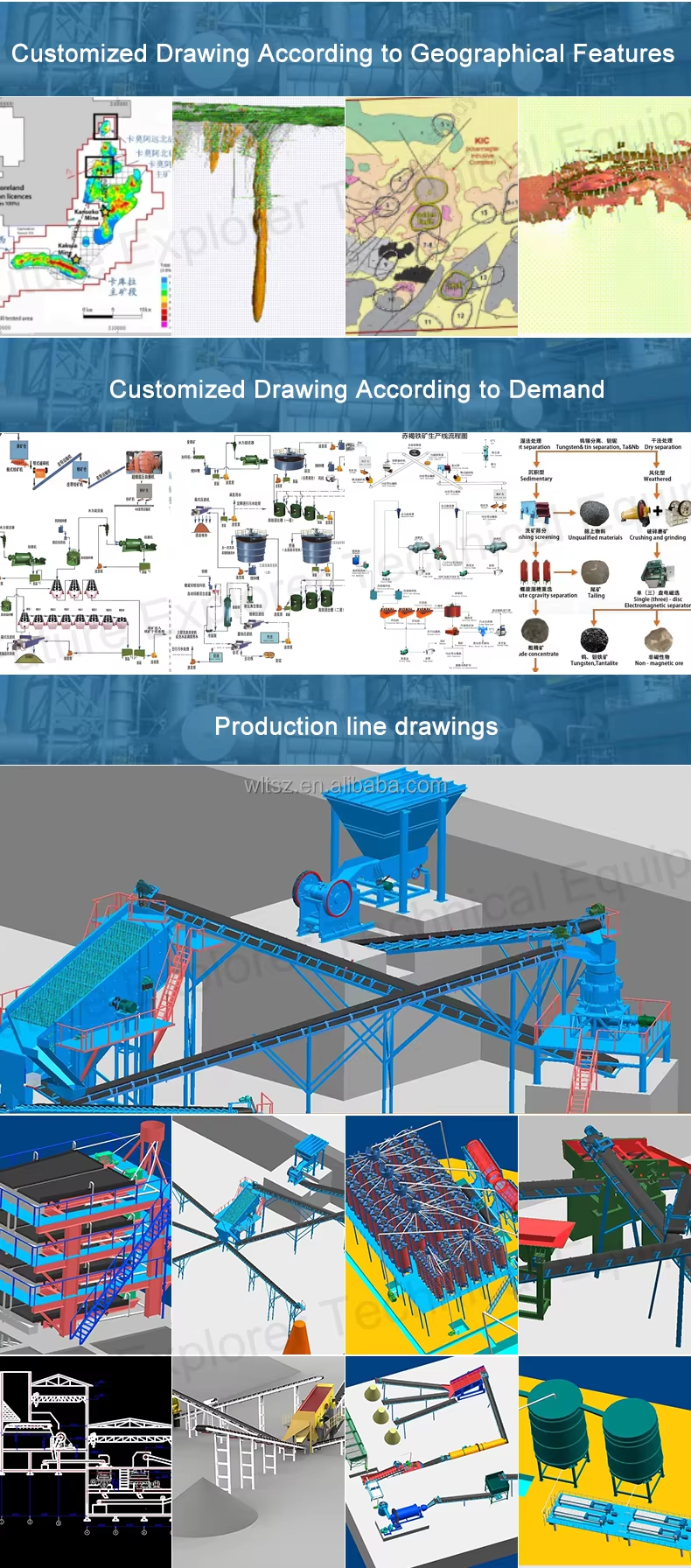

Engeering Design Drawings in the past successful cases

What we can provide:

Design:

a) Tailor-made design for each ore dressing plant

b) Non-standard parts and pipelines are designed by professionals and reviewed by the installation team

c) Fully consider installation and commissioning issues, and use steel structures when necessary

2 Procurement

a) Pay attention to the connection and capacity matching of the main and auxiliary equipment of the entire production line, and provide high-standard equipment and spare parts matching solutions;

b) Provide equipment with unified standards and adapted to foreign field conditions;

c) All documents (including 3D parts drawings) are organized and translated in a unified format;

d) Organize packaging, shipment and customs clearance according to the overall production line, installation materials, spare parts, etc.

3 Construction

a) Simulate on-site installation material plan to avoid insufficient materials or inventory backlogs, resulting in extended construction period and increased investment costs;

b) Careful construction plan, strict assessment standards, avoid repeated changes in the plan;

c) Experienced construction, installation and commissioning teams

4Full-process management services, providing integrated solutions;

5A large team of technical experts, providing operational management support;

6Superior on-site process inspection, equipment diagnosis, and management supervision capabilities of the beneficiation plant, providing personalized solutions to reduce costs and increase efficiency;

7Scientific and reasonable performance appraisal system to efficiently manage operational projects;

8The associated technical team can fully tap the potential of the project and quickly carry out on-site technical transformation

Global Sales Network:

1. Oceania: Australia, New Zealand 2.Africa: South Africa, Sudan, Zimbabwe, Ghana,Tanzania, Uganda, Congo, Zambia, Nigeria,

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Customer Photos

Certifications