High Quality PE 400X600 Mobile diesel Jaw Crusher Machine Sale

Other recommendations for your business

Contact us

Quik Detail

| Type | Jaw Crusher |

|---|---|

| Application | Mining,building |

| Motor Type | AC Motor |

| Capacity(t/h) | 110-200m3/h |

| Place of Origin | Henan, China |

| Brand Name | Huahong |

| Dimension(L*W*H) | 1700*1732*1653mm |

| Weight | 7t |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Gear, motor, Engine, Gearbox |

| Key Selling Points | Competitive Price |

| Color | Favorite |

| After sale Service | Overseas |

| Installation | Under Engineer's Guide |

| The Machines classification | Small Stone Machine |

| Product name | Widely-used Mining Equipment |

| Spare parts supply | 12 Months Guarantee |

| Max feed lump size | 340mm |

| Adjustment range | 40*90mm |

| Maine shaft speed | 275r/min |

| Local Service Location | None |

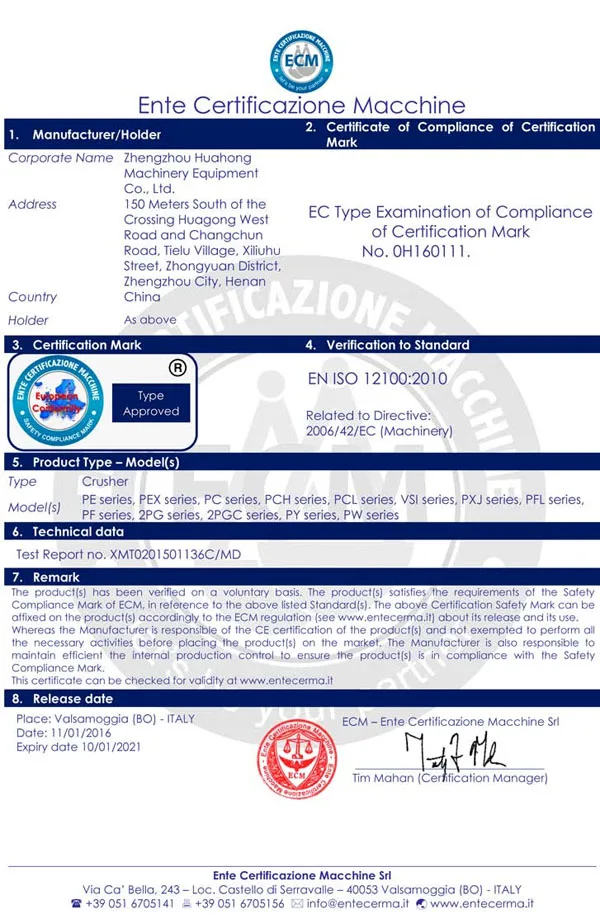

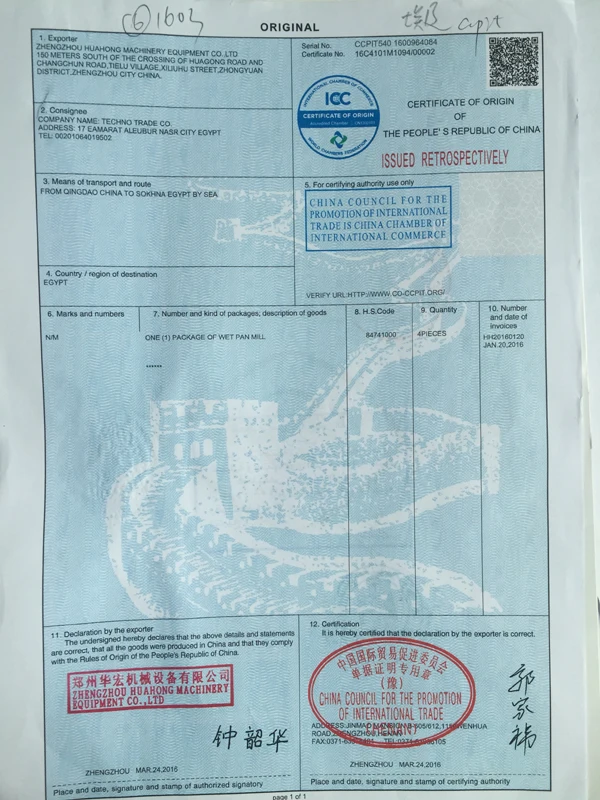

| Certification | ISO CE SGS |

| Applicable Industries | Energy & Mining |

| Showroom Location | None |

| Condition | New |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

Product Detail

High quality PE 400X600 Mobile diesel jaw crusher machine sale

400*600 Jaw crusher

Jaw crusher referred to as "jaw broken, also called mandibles crusher, jaw crusher broken stone machine, etc., have a simple pendulum jaw crusher and compound pendulum jaw crusher, it is mainly used for crushing various material compressive strength less than 320 million mpa. Anylink machine combined with the domestic and foreign advanced technology research and development of jaw crusher, a deep cavity broken, feed and crushing efficiency greatly improve, stand-alone energy saving 15%-30% , system energy saving more than double, with advanced technology, long service life, reliable operation, easy maintenance and other advantages.

Jaw crusher price:

Jaw crusher price is influenced by many factors, different manufacturers, the price will be different, suggest to buy normal manufacturer, huahong as 13 years professional crusher manufacturers, production equipment not only guaranteed quality, and high quality and low price, factory direct sale, discount more! And can be customized according to customer's actual demand, model complete, can contact our online customer service, or call our service hotline 15538238762, we will have the most professional and technical personnel to serve you, to provide you with jaw crusher latest preferential price!

Product advantages:

1.The structure is concise, the crushing force is strong

The advanced crushing technology and digital processing equipment, the internal structure is sophisticated, the crushing ability is enhanced.

2.Easy operation and maintenance

The equipment is easy to operate during use, easy to maintain and reduce downtime.

3.Manufacturing advanced, compressive resistance

The components are made of high quality materials, the movable jaw is made of cast steel and the eccentric shaft is processed by forging, which enhances the compressive and abrasion resistance.

4.Little noise, little dust

Strictly meet the national environmental protection standard, low noise, configure dust removal equipment, reduce dust generation, reduce pollution.

5.High production efficiency

Deep cavity crushing and no dead zone, no plugging phenomenon, single machine energy saving 15% ~ 30%, the system energy efficiency more than double.

6.Widely used

It has a large adjustment range, reasonable structure and small occupation area, which can meet the user's various processing demands.

Detailed parameters of the Jaw Crusher:

| Model | Feed opening size (mm) |

Max feed size(mm) |

Adjustable range (mm) |

Capacity (t/h) |

Eccentric shaft rotary speed (r/min) |

Motor power (kw) |

Total weight (t) |

Overall dimensions (L*W*H)(mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910×750×990 |

| PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000×870×990 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980×2080×1870 |

| PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070×2000×1920 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-180 | 250 | 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 90-110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 160-220 | 130-330 | 250 | 110 | 29.8 | 2710×2430×2800 |

| PE-830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 250 | 110 | 30.7 | 2740×2430×2800 |

| PE-870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 180 | 160 | 100.9 | 4200×3300×3500 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720×1950×1600 |

The working principle of jaw crusher

The crushing mode of jaw crusher is curved and dynamic extrusion. Its working principle is:

Motor drive belt and pulley, make through eccentric shaft dynamic jaw movement up and down, when moving jaw rises between the bracket and fixed jaw Angle, so as to promote dynamic jaw plate to the fixed jaw close, rather than the material being crushed or broken at the same time, achieve the purpose of broken;

When the jaw is down, the Angle of the bracket is smaller with the jaw Angle, the movable jaw plate is in the pull rod, the spring is under the action of the spring, leaving the fixed jaw plate, the broken material is expelled from the broken cavity.

Work part of the jaw crusher is two pieces of jaw plate, one is the fixed jaw plate (jaw), vertical (or the upper slightly extraversion) fixed in front of the body wall, the other one is activity jaw (dynamic jaw), tilt, and fixed jaw plate form the size of the crushing cavity cavity (work).

The movable jaw plate is a periodic reciprocating movement of the fixed jaw plate, which is sometimes separated, sometimes close, and when separated, the material enters the crushing chamber and the finished product is discharged from the lower part. When approaching, the material between the two jaw plates is crushed, bent and split and broken.

|

|

|

|

|

Packaging:

Generally,we adopt standard containers, bare main machine, motors and small parts are packed in wooden cases.Or depend on your demands.

1. Waterproof packing with the international export standard by 20ft, 40ft, 40hp container. Equipment Fittings,

Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed

by Color-Stripes Plastic Cloth.

2.The whole plant machinery size are large as normal, so we will use Waterproof cloth to pack all of them. The

motor, gear box or other easily damaged parts, we will put them into box. We have a professional shipping

department, they will try them best to save your container quantity.

Shipping:

7 days after you pay to the deposit

Pre-sales service:

Be a good consultant and assistant to customers, to ensure our customer's investment rewarded with great profit.

1.Enough details about the materials shall be learned, sometimes a test is needed for some materials.

2. Equipment of right model is selected for customers.

3. Customized products and processing flow sheet can be designed and developed to meet customer's special needs,

4. Engineer could be sent to observe customer's working site to come up with an optimized solution accordingly.

On-sales service:

Every customer is respected and convenience and reliability will be provided. We are devoted to helping you to benefit as much as possible.

1. Inspection is a must before delivering of the goods.

2. Assistance to make a construction plan by supplying all drawings and data needed.

3. Most favorable scheme for you with the guaranteed quality.

4. Timely communication to make sure improvement of project and your requirement met.

After-sales service:

1. Installation, adjustment, and testing of equipment is available.

2. Train of technicians and workers at site is promised.

3. Service engineers will not leave until ensuring the whole line running well after the installation & adjustment is finished.

4.If any failure or question about the machines or the processing line, contact us and we are available at any time.

1. Over 13 years experience in jaw crusher and mining field.

2. CE ISO SGS certificates from official govement.

3. Fisrt-class pre-sales service and after-sales service.

4. 12 months warranty for complate machine.

5. Trade arrurance service.

6. Proffssional engineers team, design as your demands.

More details PLS click on http://zzhuahong.en.alibaba.com/

F A Q:

1.How is the quality of your product?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If product quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about Price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

Email: lilyli (at) huahongjixie.net.cn

whasapp: 008613027783958

Wechat:13027783958

Skype:lilyjl11212