Hole Punch Press C Frame Single Crank Eccentric Mechanical Power Press Machine Punching Machine

US $2,000.00 / piece

1 piece(s)Minimum order

slide stroke (mm):

80

machine type:

Hot Forging Hydraulic Press

ejector force (kn):

250t

return force (kn):

250 kN

system:

Servo

place of origin:

Jiangsu, China

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| slide stroke (mm) | 80 |

|---|---|

| machine type | Hot Forging Hydraulic Press |

| ejector force (kn) | 250t |

| return force (kn) | 250 kN |

| system | Servo |

| place of origin | Jiangsu, China |

| brand name | KINGBALL |

| voltage | 220v/380v |

| dimension(l*w*h) | 690x980x2120 mm |

| weight (t) | 2.45 T |

| model number | JH21-25T |

| motor power (kw) | 2 kw |

| key selling points | Multifunctional |

| warranty | 1 Year |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, Pressure vessel, Engine |

| Product name | Four Column Hydraulic Press |

| Machine Type | Hydraulic Press |

| Power Source | Hydraulic Power |

| Keyword | Hydryalic Press |

| After-sales Service Provided | Online Support |

| Function | Metal Processing |

| Application | Metal Sheet Steel Forming |

| Structure | Four Column Machine |

| Usage | Pressing Metal Sheet |

| Name | Hydraulic Punch Press Machine |

| Condition | New |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location | Turkey, Germany, Saudi Arabia, Mexico, Spain, Argentina, Chile, None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 2 years |

Product Detail

Products Description

Details Images

Specifications | Unit | JH21-250 | JH21-315 | ||||||

Type | H | S | H | S | |||||

Nominal strength | CN | 2500 | 3150 | ||||||

Nominal stroke | Mmm | 6.5 | 6.5 | 7 | 7 | ||||

Slide stroke | Mmm | 160 | 220 | 160 | 220 | ||||

Slide Strokes Per Minute | festivals | Min-1 | 45 | 30 | 45 | 30 | |||

variable | 30-55 | 20-35 | 30-55 | 20-35 | |||||

Maximum Die Set Height | Mmm | 530 | 500 | 530 | 500 | ||||

The height adjustment | Mmm | 120 | 120 | ||||||

Between slide center and frame | Mmm | 450 | 450 | ||||||

Column spacing | Mmm | 980 | 980 | ||||||

Bottom size of slide | L×R | Mmm | 950 | 950 | |||||

F×B | Mmm | 700 | 700 | ||||||

Shank hole size | slide | Mmm | 70 | 70 | |||||

depth | Mmm | 130 | 130 | ||||||

Strengthen size | L×R | Mmm | 1500 | 1540 | |||||

F×B | Mmm | 880 | 880 | ||||||

Punching hole diameter | Mmm | 240 | 240 | ||||||

Strengths thickness | Mmm | 190 | 190 | ||||||

Strengthen surface height | Mmm | 1000 | 1000 | ||||||

Overall dimensions | F×B | Mmm | 2660 | 2720 | |||||

L×R | Mmm | 1640 | 1680 | ||||||

H | Mmm | 3850 | 3850 | ||||||

Distance Between Foundation Screws | F×B | Mmm | 2100 | 2140 | |||||

L×R | Mmm | 1460 | 1500 | ||||||

engine | power | Kw | 22 | 30 | |||||

Weight (Approx.) | kg | 23200 | 26600 | ||||||

Features:

1,Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability;

2,Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact;

3,The crankshaft undergoes gringding treatment after high frequency quenching;

4,Lengthened six-face rectangle guide with a surface of bronze plate;

5,Vertical located crankshaft, compact structure;

6,PLC control and imported safety duplex valve;

7,Wet type combined multi discs friction clutch and brake;

8,Hydraulic onerload protected.

Details:

1,The JH21 C-frame single crank press is suitable to process the lightweight and thin materials through blanking, piercing,

bending, forming, interlink with ROT line or transfer unit. Suitable for single and progressive die application, and it owns the

capacity ranging from 25 ton to 400 ton

2,The press use high torque and low noise wet clutch and brake.

3,The steel welded body ensures rigid frame with less deflection. High accuracy transmission gears and high rigidity crank ensure

press long life and accuracy. Forced lubrication system with default monitor ensures the operation reliability.

4,User-friendly design and all-function electric control system enable the accessories to attach easily.

1,Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability;

2,Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact;

3,The crankshaft undergoes gringding treatment after high frequency quenching;

4,Lengthened six-face rectangle guide with a surface of bronze plate;

5,Vertical located crankshaft, compact structure;

6,PLC control and imported safety duplex valve;

7,Wet type combined multi discs friction clutch and brake;

8,Hydraulic onerload protected.

Details:

1,The JH21 C-frame single crank press is suitable to process the lightweight and thin materials through blanking, piercing,

bending, forming, interlink with ROT line or transfer unit. Suitable for single and progressive die application, and it owns the

capacity ranging from 25 ton to 400 ton

2,The press use high torque and low noise wet clutch and brake.

3,The steel welded body ensures rigid frame with less deflection. High accuracy transmission gears and high rigidity crank ensure

press long life and accuracy. Forced lubrication system with default monitor ensures the operation reliability.

4,User-friendly design and all-function electric control system enable the accessories to attach easily.

HOT SALE

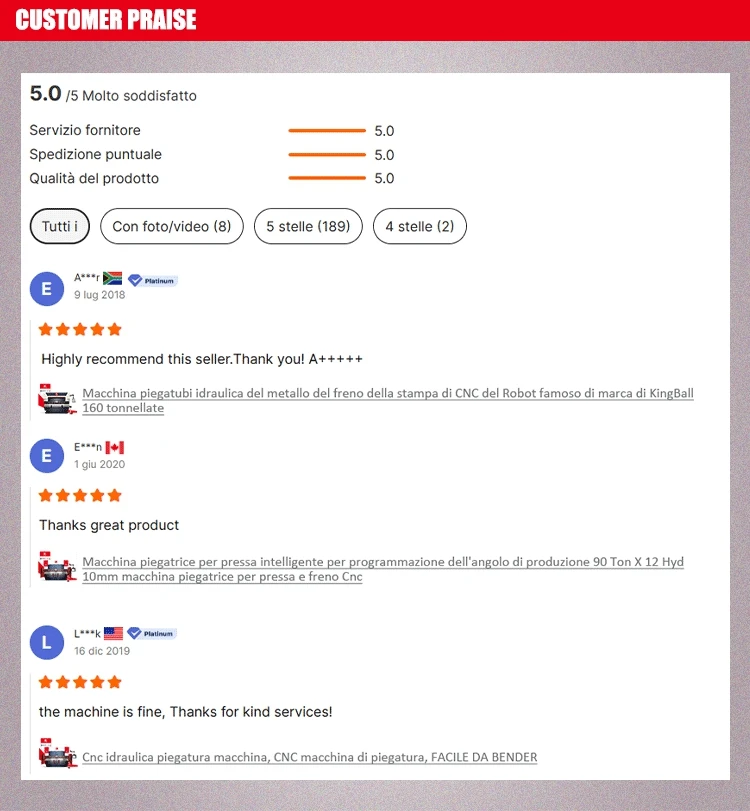

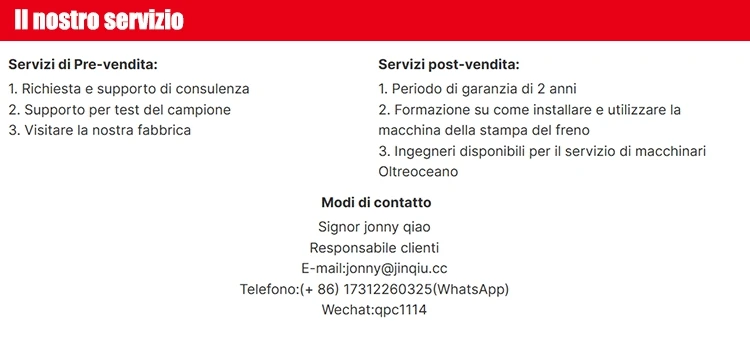

Pre-sales services:

1. inquiry and consulting support

2. sample testing support

3. visit our factory

After-sales services:

1. 2 years warranty period

2. training how to install and use the brake press machine

3. engineers available to service machinery

overseas

overseas

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis/Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days.

2.What is the average lead time?

For samples, the lead time is about 7 days.

For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products.

If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.

4.What is the product warranty?

We warranty our materials and workmanship.

accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.

4.What is the product warranty?

We warranty our materials and workmanship.

Our commitment is to your satisfaction with our products. In warranty or not, it is the

culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging.

culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging.

We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items.

Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way.

By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of

amount, weight and way. Please contact us for further information.

amount, weight and way. Please contact us for further information.