Hydraulic R Series Radial Servo Power Tooling Turret High Performance Bmt55 Cnc Lathe Live Turret

US $2,574.00-2,860.00 / set

1 set(s)Minimum order

place of origin:

Jiangsu, China

weight (kg):

54

video outgoing-inspection:

Provided

machinery test report:

Provided

brand name:

DRAKE

application:

Turning Tool

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Jiangsu, China |

|---|---|

| weight (kg) | 54 |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| brand name | DRAKE |

| application | Turning Tool |

| warranty | 1 Year |

| core components | motor |

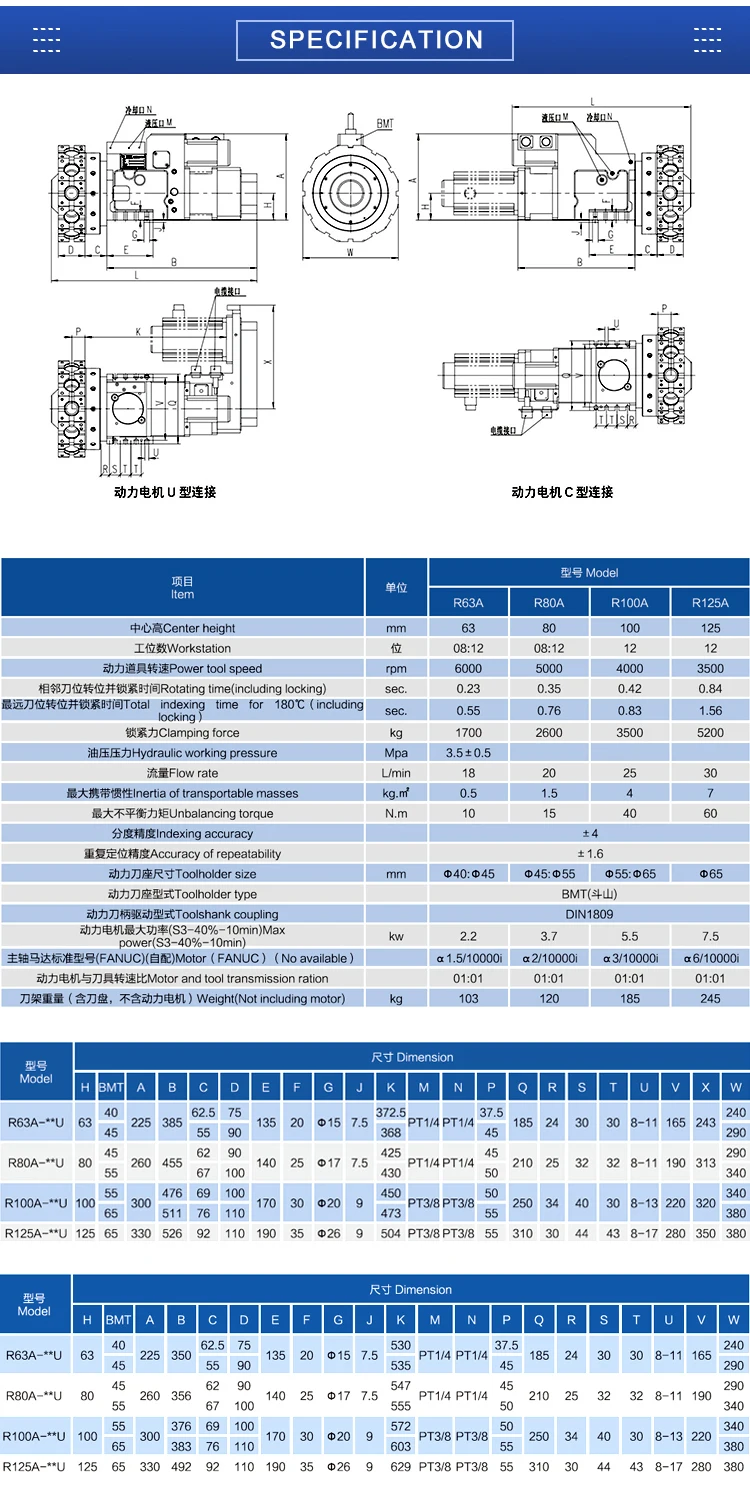

| Center Height | 63mm |

| Workstation | 08:12 |

| Power Tool Speed | 6000rpm |

| Rotating Time (including locking) | 0.23 sec. |

| Total Indexing Time for 180° | 0.55 sec. |

| Clamping Force | 1700kg |

| Hydraulic Working Pressure | ±3.5 Mpa |

| Flow Rate | 18 L/min |

| Intertia of Transportable Masses | 0.5 kg.m² |

| Unbalancing Torque | 10 N.m |

| Condition | New |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Retail, Construction works , Energy & Mining, Advertising Company |

| Showroom Location | None |

| Marketing Type | New Product 2020 |

Product Detail

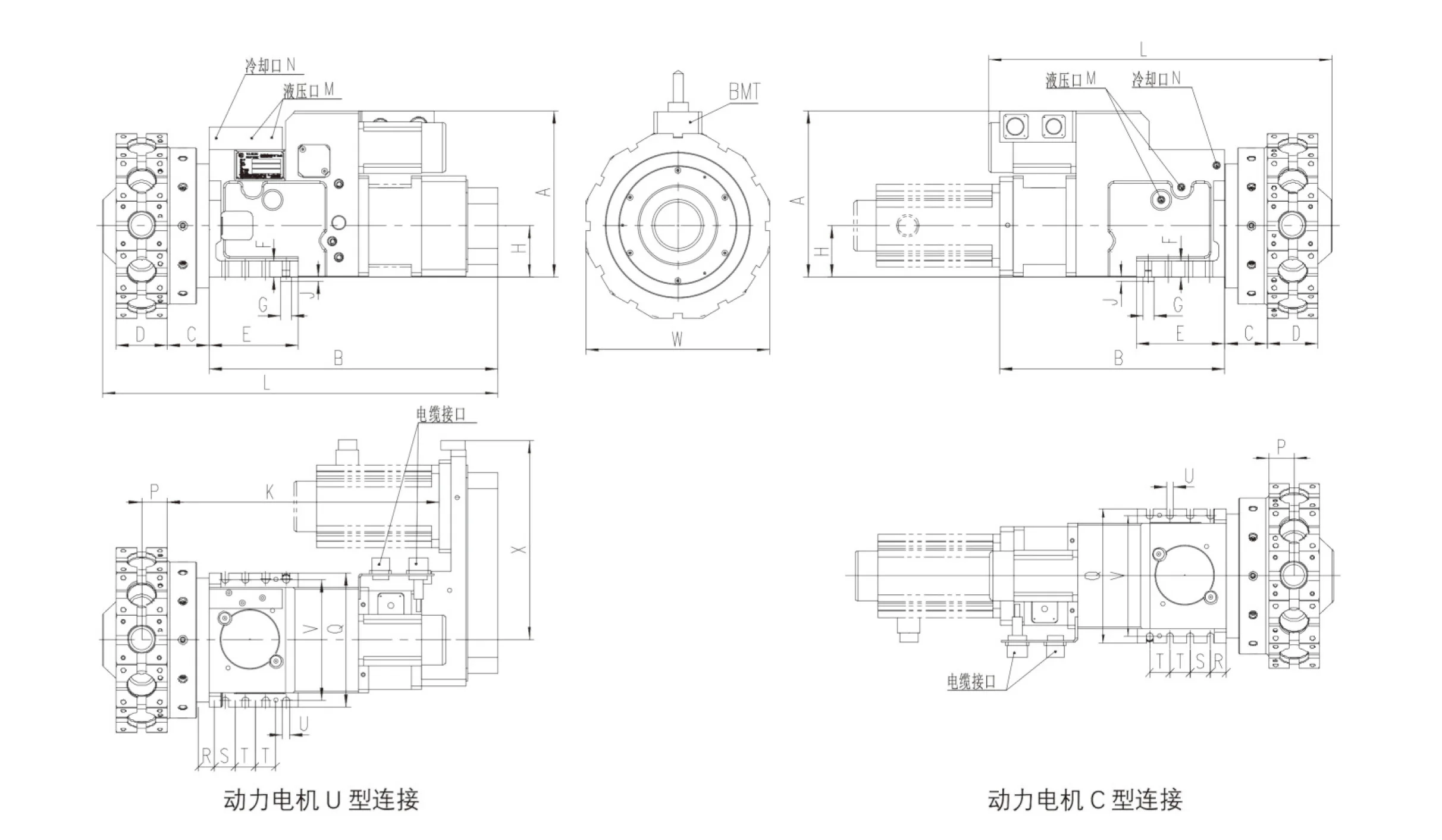

R Series Radial Servo Power Toolina Turret

1. Taking SLT series servo turret as the platform,external power module is added to compose SLTR series radial power tooling servo,which has reasonably compact layout.

2. High-precision triple hirth coupling and hydraulic clamping devices for loosening,high indexing accuracy and reliable clamping.

3. Separate spindle servo motor under simple control provides toos driving force. Modular interface can adapt to a variety of the spindle motor,whose maximum power up to 11kw

4. The BMT driven tool-holder can be fixed to each position of the turret,and it can only be operated at the work position.The tool-holder type is designed to accord with the manufacturers standards of DOOSAN,and the coupling interface type is designed to accord with the DIN1809 standard.

3. Separate spindle servo motor under simple control provides toos driving force. Modular interface can adapt to a variety of the spindle motor,whose maximum power up to 11kw

4. The BMT driven tool-holder can be fixed to each position of the turret,and it can only be operated at the work position.The tool-holder type is designed to accord with the manufacturers standards of DOOSAN,and the coupling interface type is designed to accord with the DIN1809 standard.

NOTE:

1. Confirm various parameters when choosing models of turret. Choose the number of stations according to quantity of part procedure and complicacy.

2. Choose tool specifications according to model of machine tool and cutting force. Choose the front type or rear type tool turret according to the cutting directions of the machine tool.

3. After the mounting of boring cutter seat of horizontal turret, Self-bore the inner hole according to the size of boring bar and make a corresponding mark. The tool should be fixed in the former position in the later mounting.

4. The distance tool reaching out of upper housing distance is usually not more than 2/3 upper housing size. Please note when placing an order,if more than the limit.

5. Touch by hand or other things is forbidden when turret is running to avoid injury or damage.

6. If customers have any special requirements or changes in parameters, please offer some data and contact with our company.

2. Choose tool specifications according to model of machine tool and cutting force. Choose the front type or rear type tool turret according to the cutting directions of the machine tool.

3. After the mounting of boring cutter seat of horizontal turret, Self-bore the inner hole according to the size of boring bar and make a corresponding mark. The tool should be fixed in the former position in the later mounting.

4. The distance tool reaching out of upper housing distance is usually not more than 2/3 upper housing size. Please note when placing an order,if more than the limit.

5. Touch by hand or other things is forbidden when turret is running to avoid injury or damage.

6. If customers have any special requirements or changes in parameters, please offer some data and contact with our company.

No. | A | B | C | D |

Part name | BMT cutter head | Cutter Front Cover and Logo | BMT live tool (customer self-configured) | Servo turret body |

No. | E | F | G | H |

Part name | Turret Index Motor | cable connector | Spindle motor (not supplied) | Motor connection board |

No. | I | J | K | L |

Part name | Coolant inlet | Hydraulic release interface | Hydraulic locking interface | guide plate |

No. | M | N | Z | |

Part name | power transmission case | The central axis | coupling sleeve |