Innovative Solid Bowl Decanter Centrifuge From Technology Leader, Since 1954

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Jiangsu, China |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Bearing, motor, Gear, Pump |

| brand name | HUADING |

| voltage | 220/ 380 / 415 |

| power(w) | 5.5-132 |

| dimension(l*w*h) | 1*3*1.5 |

| warranty | 1 Year |

| key selling points | Easy to Operate |

| After-sales Service Provided | Field installation, commissioning and training |

| Certification | CE |

| Type | Centrifuge |

| Condition | New |

| Warranty of core components | 1 Year |

| Applicable Industries | Food & Beverage Factory, Farms, Energy & Mining |

| Showroom Location | Canada, Turkey, United Kingdom, Viet Nam |

| Marketing Type | Hot Product 2022 |

| Weight | 10000 |

Product Detail

Wide-ranging performance

Decanter centrifuge from Huading Separator provide exceptional performance whenseparating solids from liquids, andmake it possible to do so continuously,efficiently and controllably.

Huading decanter centrifuges are designed to handle a wide range ofsolid particles with diameters from 5mm to a few microns.

Decanter centrifuge can also handle slurries with a solid content from as low as 0.1% w/w to more than 65% w/w.

Working principle

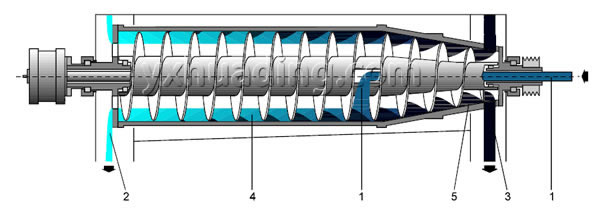

2 - phase separation

- 1. Feed

- 2. Liquid phase

- 3. Solids phase

- 4. Pond

- 5. Dry beach

The feed suspension is introduced through an inlet pipe into the feed zone of the conveyor where it is accelerated and directed into the interior of the bowl. The settled solids are conveyed axially towards the small end of the bowl by means of the screw conveyor, which rotates at a slightly different speed than the bowl. On the way to the discharge ports the solids are lifted out of the pond up along the dry beach. The solids are finally discharged from the bowl through the discharge ports into the collecting chamber of the casing that surrounds the bowl. From there the solids are removed by gravity through the outlet funnel. The liquid phase forming a hollow cylinder due to the centrifugal force, and flows towards the large end of the bowl. There the liquid overflows adjustable plate dams into the centrate chamber of the casing and is discharged by gravity.

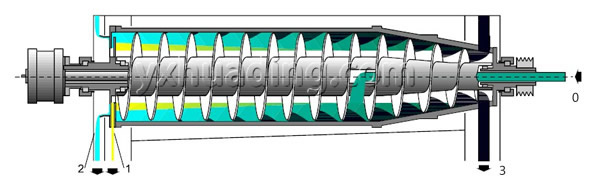

3 - phase separation

- 0. Food

- 1. Light liquid phase

- 2. Heavy liquid phase

- 3. Solids phase

The light liquid phase is discharged into the casing through radial holes in the large end hub. The heavy liquid phase is discharged through axial holes in the large end hub. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The liquid level is controlled by plate dams. In order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub. The heavy liquid phase has to pass under the separating plate before being discharged into the casing. The liquid radius for the heavy liquid phase is controlled by plate dams. The solids are discharged in the normal way.

Features

- All parts coming into contact with the product are made of stainless steel.

- 3-phase AC motor for controlled torque starting via frequency converter

- Bowl speed is adjustable via VFD to obtain the required G-force for optimized separation

- Pond depth in the bowl is adjustable for optimized balance between liquid clarity and solids dryness

- Conveying speed is adjustable for optimized balance between liquid

- Low personnel costs due to continuous and automatic operation.

- Highest g-force for higher solids output

- Automatic adjustment of differential speed via VFD

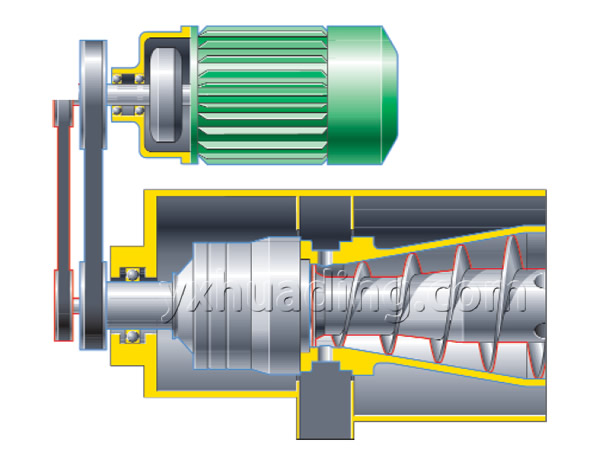

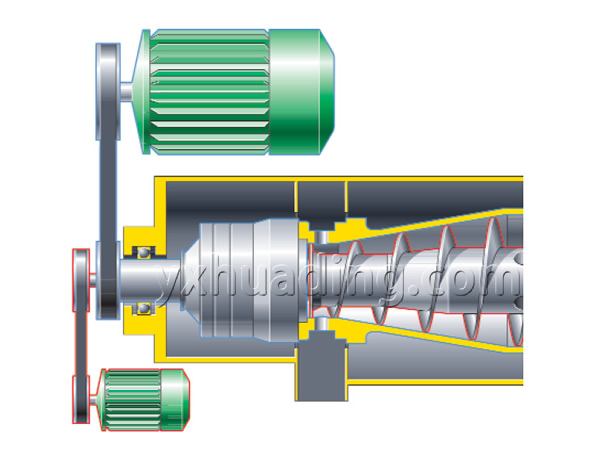

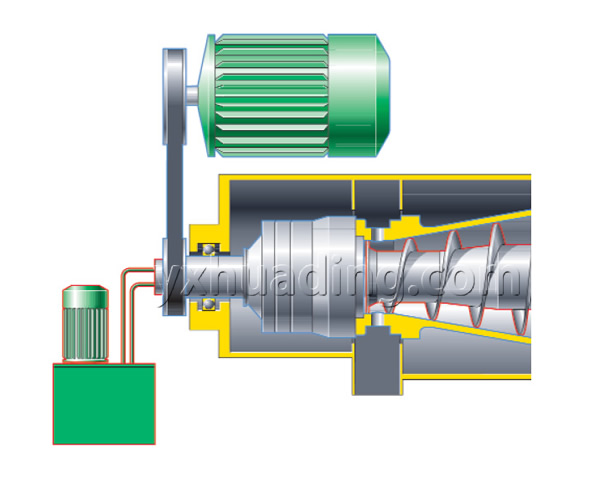

- Two motor drive

- Belts for both primary motor and secondary motor

The bowl, conveyor, inlet tube, outlets, cover and other parts in direct contact with the process media are all made of stainless steel. The discharge ports, conveyor flights and feed zone are protected with materials that are highly resistant to erosion. The frame is made of mild steel with an epoxy enamel finish.

Huading Separator supply a wide range of wear protection to meet the requirements of the many different applications, including:

- Welded hard facing or spray coating

- Ceramic

- Tungsten carbide tiles

- Chilled hard metal portcastings

- Plastic liners

Two motor drive, it enable the differential speed to be regulated cost-effectively under good operating conditions; wide regulating ranges are possible. The secondary motor sets the input shaft of the gear in motion and generates the differential speed as a function of bowl speed and gear transmission. The differential speed can easily be regulated by changing the motor speed. Two motor drive are used whenever solid volumes fluctuate significantly, when solids are conveyed under difficult conditions and when particularly stringent requirements are applicable with regard to residual water content.

Technical specification

Huading Separator has been developing and manufacturing decanters for over 15 years and is one of the Chinese

leading decanter manufacturers.Huading Separator has more experience and expertise than any other decanter manufacturer when it comes to applying and using decanters for the purpose of industrial & municipal wastewater treatment.

| bowl ID (mm) |

bowl speed (rpm) |

L / D | g - force | capacity (m3/h) |

solids removal (m3/h) |

primary motor (Kw) |

Weight (Kg) |

Dimension (mm) |

| 250 | 4800~5400 | 3.0~5.0 | 2000~3500 | 3~5 | 0.4 | 11 | 760 | 1600×1100×850 |

| 300 | 4200~4600 | 3.0~5.0 | 2000~3500 | 3~15 | 0.8 | 11~15 | 1500 | 2470×1230×850 |

| 350 | 3700~4200 | 3.0~5.0 | 2000~3500 | 5~20 | 1.2 | 5~22 | 2000 | 2790×1300×880 |

| 400 | 3200~3900 | 3.0~4.8 | 2000~3500 | 5~30 | 2 | 18.5~30 | 2600 | 2950×1400×850 |

| 450 | 3000~3700 | 3.0~5.0 | 2000~3500 | 5~45 | 2.5 | 22~37 | 3200 | 3300×1500×920 |

| 530 | 2700~3450 | 3.0~5.0 | 2000~3500 | 10~80 | 5 | 30~55 | 5200 | 3730×1600×1100 |

| 580 | 2600~3300 | 3.0~5.0 | 2000~3500 | 10~90 | 6 | 45~75 | 6900 | 4000×1400×1600 |

| 650 | 2400~3100 | 3.0~5.0 | 2000~3500 | 20~105 | 8 | 37~90 | 8200 | 4300×1900×1350 |

| 760 | 2200~2900 | 3.0~5.0 | 2000~3500 | 30~120 | 12 | 55~135 | 12000 | 5000×2500×1500 |

| 900 | 1800~2600 | 3.0~5.0 | 2000~3500 | 40~180 | 16 | 75~160 | 18000 | 6500×2700×1500 |

After service

Technical service:

- technical direction when installation, debugging

- training for operation and maintain worker

Training:

- separator working principle and structure

- operation regulation and attention

- machine maintains

Experience

Huading Separator has been developing and manufacturing centrifuges for nearly 60 years, and is one of the Chinese leading manufacturer. Huading Separator has more experience and expertise than any other separator manufacturer when it comes to applying and using decanter centrifuge for the purpose of continuous separation.

For more information, please refer to:huading-separator.com