KERUI High Temperature 128kg/cm3 Ceramic Fiber Boards for Stove

US $3.00-5.00 / piece

100 piece(s)Minimum order

Place of Origin:

Henan, China

Brand Name:

KERUI, KERUI Refactory

Grade:

HAZ (High Aluminum Zirconium)

Working Temperature:

1260C

Density (kg/m³ ):

128

Al2O3:

0.39-0.42%

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Place of Origin | Henan, China |

|---|---|

| Brand Name | KERUI, KERUI Refactory |

| Grade | HAZ (High Aluminum Zirconium) |

| Working Temperature | 1260C |

| Density (kg/m³ ) | 128 |

| Al2O3 | 0.39-0.42% |

| SiO2 | 46-48% |

| CaO | 37-41% |

| Bulk & Density | 230±10%g/cm3 |

| Model | Customizable |

| Size | Customizable |

| Certificate | ISO9001 CE MSDS |

Product Detail

What's the Ceramic Fiber Blankets?

Describtion:

Ceramic fiberboard is a high-temperature insulation material, mainly made of ceramic fiber. It has excellent thermal insulation, high temperature resistance, corrosion resistance and thermal shock resistance, so it is widely used in lining materials of industrial kilns, boilers, and high-temperature equipment. Ceramic fiberboard is not only light and high-strength, but also can withstand temperatures up to 1000°C, which can effectively reduce heat loss and improve energy efficiency.Parameter:

Item | Ordinary Type | Standard Type | High Purity Type | High Alumina Type | Zirconium Containing Type | ||||

Classification Temperature | 1100 ℃ | 1260 ℃ | 1260 ℃ | 1360 ℃ | 1430 ℃ | ||||

Working Temperature | <1000 ℃ | 1050 ℃ | 1100 ℃ | 1200 ℃ | 1350 ℃ | ||||

Bulk & Density | 260-320 kg/m³ | ||||||||

Permanent Liner Change, % | -4 (1000℃) | -3 (1000℃) | -3 (1000℃) | -3 (1250℃) | -3 (1350℃) | ||||

Heat Conductivity Coefficient, W/(m·k) (Bulk Density 128kg/m³) | 0.09 (400℃), 0.176 (800℃), 0.22 (1000℃) | ||||||||

Strength of Extension | 0.5 Mpa | ||||||||

Al2O3, % | 44 | 46 | 46~49 | 52~55 | 39~40 | ||||

Al2O3+SiO2, % | 96 | 97 | 99 | 99 | - | ||||

Al2O3+SiO2+ZrO2, % | - | - | - | - | 99 | ||||

ZrO2, % | - | - | - | - | 15~17 | ||||

Fe2O3, % | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | ||||

Na2O+K2O, % | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | ||||

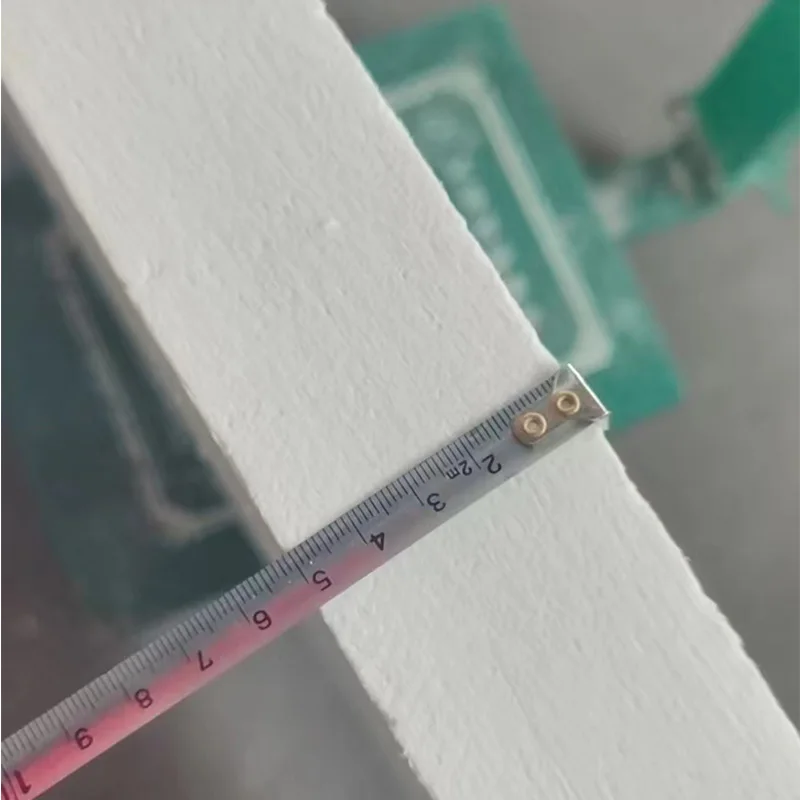

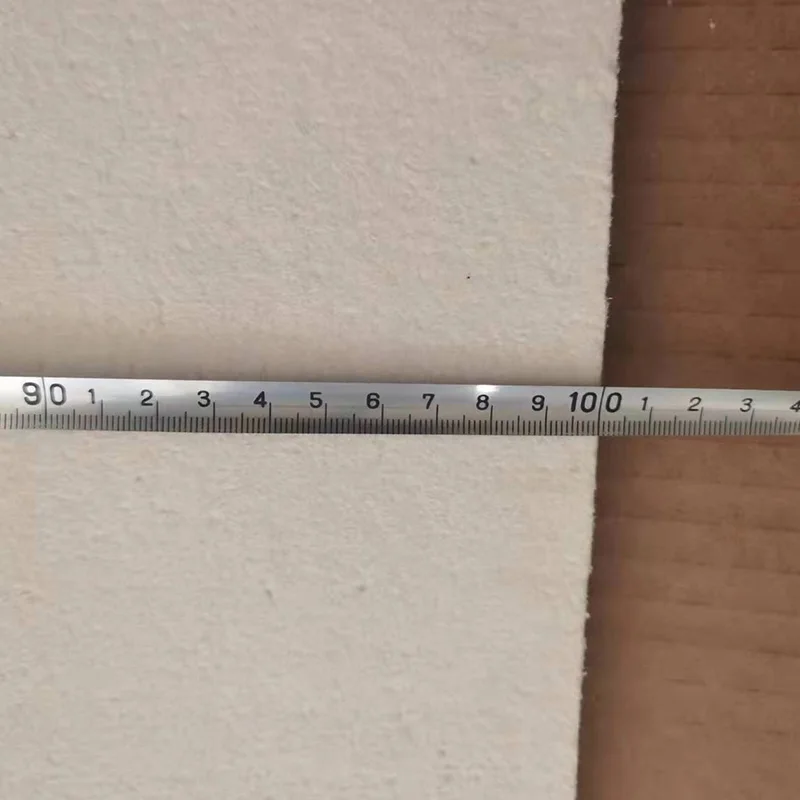

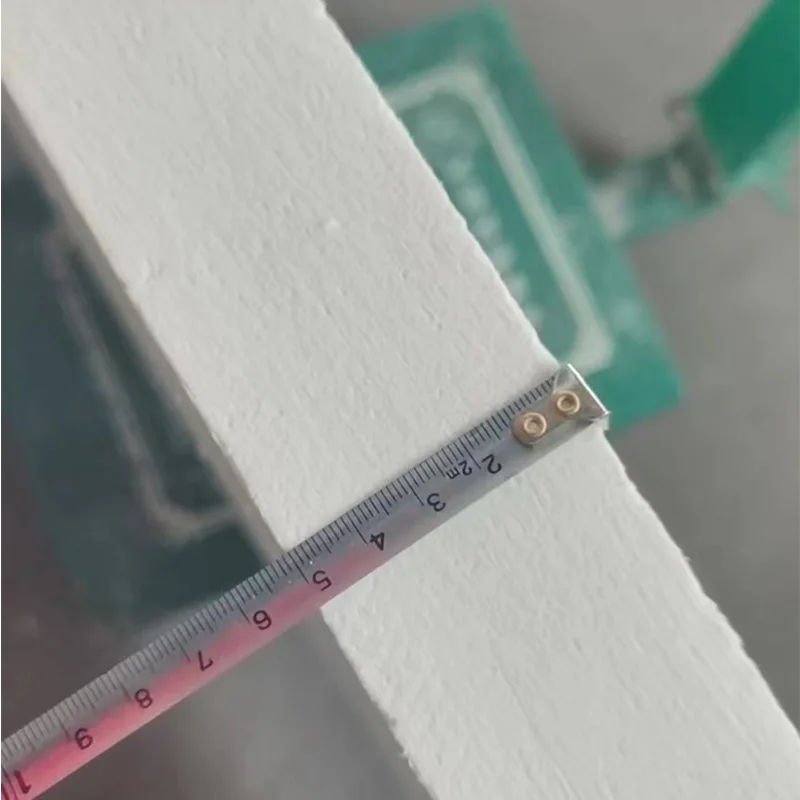

Size, mm | Length1000mm, Width1200/1000, Thickness 20-50mm, Customized Size | ||||||||

Where Use the Ceramic Fiber Board?

Main Application:

Industrial Kiln

● Kiln lining: Ceramic fiberboard is often used for high-temperature kiln lining in the steel, glass, ceramic and other industries, which can effectively reduce heat loss and improve energy efficiency.

● Kiln door seal: As the material of kiln door or other high-temperature sealing parts, ceramic fiberboard is resistant to high temperature, not easy to deform, and can maintain a good sealing effect.

Metallurgical Industry

● Steelmaking and casting equipment lining: Ceramic fiberboard is used for the lining of steelmaking furnaces, casting equipment, induction furnaces and other equipment to reduce heat conduction and enhance the durability of equipment.

● Casting insulation: Used in casting molds of high-temperature metals to provide insulation and heat insulation effects.

Petrochemical Industry

● High-temperature pipeline insulation: Ceramic fiberboard can be used for the insulation of chemical reaction equipment and pipelines at high temperatures to ensure the stability and safety of equipment operation.

● High-temperature reactor lining: High-temperature resistant lining used for petrochemical reactors, which can resist chemical corrosion and high-temperature impact.

Power Industry

● Boiler Insulation: Insulation lining material for power boilers, effectively improving the thermal efficiency of equipment.

● Turbine Insulation: Used for insulation of turbines and generators, reducing heat loss of equipment and ensuring efficient operation.

Aerospace

● Aircraft Engine Insulation: Due to the high temperature resistance and lightweight characteristics of ceramic fiberboard, it is widely used in the insulation and fire protection systems of aircraft engines.

● Thermal Insulation Protection of Rockets and Spacecraft: Ceramic fiberboard has excellent stability in high temperature environments and can provide protection for rockets, spacecraft, etc.

Construction Industry

● Fire Doors and Firewalls: The fire resistance of ceramic fiberboard makes it an ideal material for building components such as fire doors and firewalls, which can prevent the spread of fire.

● Flue Lining: As the lining of high-temperature flues, it prevents heat loss and improves the fire resistance of buildings. Automobile Industry

● Exhaust System Insulation: Ceramic fiberboard can be used in automobile exhaust systems to reduce system temperature and prevent heat from spreading to other parts of the vehicle body.

● Exhaust System Insulation: Ceramic fiberboard can be used in automobile exhaust systems to reduce system temperature and prevent heat from spreading to other parts of the vehicle body.

● Sound and heat insulation: Ceramic fiberboard provides heat and sound

insulation in the engine compartment and exhaust system of some high-performance vehicles.

insulation in the engine compartment and exhaust system of some high-performance vehicles.

Home Appliance Industry

● Household appliance insulation: Insulation material for high-temperature home appliances such as electric ovens and microwave ovens, providing safety and energy saving effects.

Fireproof Materials

● Fireproof insulation board: Used in fire walls, fire partitions and other occasions, it has flame retardant and heat insulation effects and is widely used in buildings or equipment that require strict fire protection requirements.

Ceramic fiberboard not only provides high temperature protection in these fields, but also helps reduce energy consumption and improve the durability and safety of equipment and facilities.

Ceramic fiberboard not only provides high temperature protection in these fields, but also helps reduce energy consumption and improve the durability and safety of equipment and facilities.

Why Choose Ceramic Fiber Board?

Main Feature:

● Excellent High Temperature ResistanceCeramic fiber boards can withstand temperatures up to 1000°C to 1600°C and are suitable for high temperature environments, such as industrial kilns, heating equipment, etc.

● Remarkable Thermal Insulation Effect

Its thermal conductivity is very low, which can effectively reduce heat conduction, significantly improve thermal insulation performance, reduce energy consumption, and save energy.

● Strong Thermal Shock Resistance

Ceramic fiber boards can withstand frequent and rapid temperature changes and will not crack or deform due to sudden cooling or heating. They are especially suitable for use in extreme temperature environments.

● Lightweight and High Strength

Compared with traditional refractory materials, ceramic fiber boards are lightweight and easy to install and transport. At the same time, they are strong enough to meet the support needs of various high-temperature equipment.

● Good Corrosion Resistance

Ceramic fiber boards have good acid and alkali corrosion resistance and can be used in complex chemical environments for a long time. They are suitable for petrochemical, chemical and other industries.

● Convenient Construction

Ceramic fiber boards are easy to cut and install, are lightweight and have high hardness, reducing construction difficulty and time costs.

● Environmental Protection and Safety

Ceramic fiber boards are inorganic materials with good environmental protection properties. They do not release harmful gases at high temperatures and are harmless to the human body and the environment.

Email: sales@keruirefra.com

Cell/Online: +86 173 4499 8507

Why Choose KERUI?

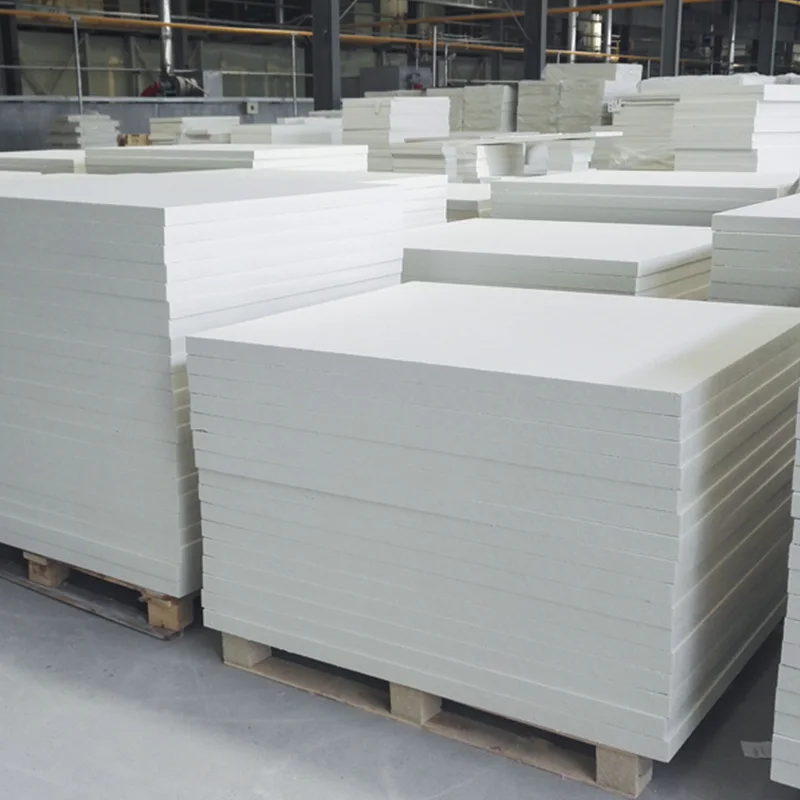

Factory:

Zhengzhou Kerui Industrial Development Co., Ltd. is a branch of Zhengzhou Kerui (Group) Refractory Co., Ltd.. We provide all types of refractory products, including refractory bricks and materials, insulation bricks and materials, kiln shelves and new materials, etc. Kerui Refractory is located in the largest refractory industry zone: Chaohua Town, Xinmi City, Henan Province, China.

Founded in 2004 with a registered capital of 81.8 million Yuan, Zhengzhou Kerui Refractory Material Co. , Ltd. is located in the refractory industry base of Chaohua town, Xinmi Province, After 20 year’s hard work and tenacious struggle , we walked out of a“Product oriented, service first” healthy and rapid development of the road, has developed into a Refractory R & D, production, sales, Product Technology Solutions, Project EPC general contracting services in one of the modern integrated enterprise group.

KERUI Teams:

Kerui has an exclusive R&D team, a professional sales team, an experienced technical guidance team, and a top after-sales service team for every customer.

Professional R&D Team

Kerui own 50000m² factory, R&D, production, sales, delivery as one, fully equipped, own patents, support customization.

Professional Sales Team

Kerui has its own sales and service team, proficient in foreign languages, instant communication with customers and can solve customer problems at first time.

Professional Solutions

Kerui has EPC capability, can undertake customer projects, has professional technical experts, according to customer needs to develop the most perfect plan.

Professional After-sale Team

Kerui has its own professional after-sales team, once the customer has any technical problems, it can respond and solve within 1 hour.

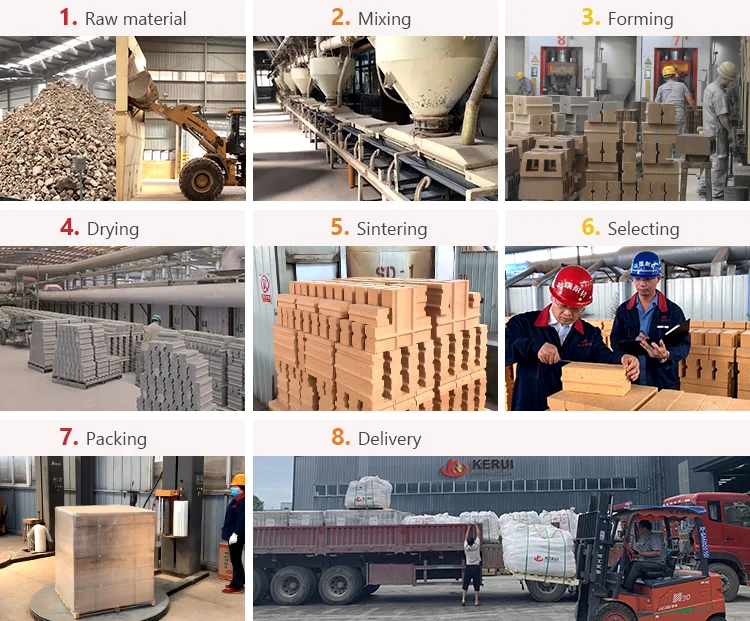

Flow of Production:

Raw Material Preparation: Select suitable refractory materials and crush and grind them.

Batching and Mixing: Weigh and mix various raw materials according to the formula requirements, and add binders and moisture.

Molding: Press the mixed slurry into shape, or form it by extrusion.

Drying: Dry the formed bricks naturally or quickly to remove excess moisture.

Firing: Firing the dried bricks in a high-temperature kiln to form a stable refractory structure, and then cool it.

Inspection: Check the appearance, size, and physical properties to ensure that they meet quality standards.

Packaging and Storage: Pack qualified refractory bricks and store them under appropriate conditions.

Shipping: Ship the packaged refractory bricks to customers according to order requirements.

The production process of refractory bricks requires strict quality control at every link, from the selection of raw materials to the testing of finished products. Each step is related to the performance and quality of the final product. Through scientific management and advanced equipment, we can ensure the production of high-quality refractory bricks to meet the needs of various high-temperature industries.

Customer Visit:

Welcome to Kerui, our ingenious production base. We will show you Kerui's craftsmanship and innovative ideas. We have always adhered to the business philosophy of "quality first, customer first". Welcome everyone to experience our products and services up close. We will be your trusted partner. Welcome everyone to come here to find business opportunities and seek common development.

Partners:

KERUI refractory products have been exported to many countries such as Russia, Korea, Indonesia, Turkey,Egypt and South Africa etc.

Keeping long term cooperation with some world famous companies including RUSAL, ALBA, CHALCO, POSCO, PSM.

Keeping long term cooperation with some world famous companies including RUSAL, ALBA, CHALCO, POSCO, PSM.

What do Customers Say?

Rusal Group of Russia:

“As a long-term partner of Kerui Refractory, we always purchase insulation bricks and refractory bricks and other materials from Kerui Refractory regularly. The product quality of Kerui Refractory is very stable,. We have never found any quality problems. When we encountered problems, Kerui Refractory will solve them positively.”

Kalugin Hot Blast Stove:

“I’m satisfied with refractory bricks and insulation bricks from Kerui Refractory. The appearance of these bricks is neat, the color is uniform, and the use experience is beyond imagination. More importantly, Kerui Refractory provides professional technical service for us, which saves our time and energy greatly.”