Laos 80-100tph Hard Rock Gold Processing Plant, Gold Mining Equipment Ball Grinding Mill Have in Stock

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine, motor |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 20-150/h |

| Place of Origin | Jiangxi, China |

| Brand Name | Jiangxi Hengchang Kaolin Processing Plant |

| Dimension(L*W*H) | 11000*7200*5700mm |

| Weight | 110000 KG |

| Warranty | 18 Months |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Name | Gold Mining Equipment |

| Max feeding size | 25mm |

| Capacity | 25-150t/h |

| Max balls loading | 13tons |

| Engine | Motor or Diesel Engine |

| Color | Blue Or As Your Request |

| Material | Carbon Steel |

| Liner material | Manganese Steel |

Product Detail

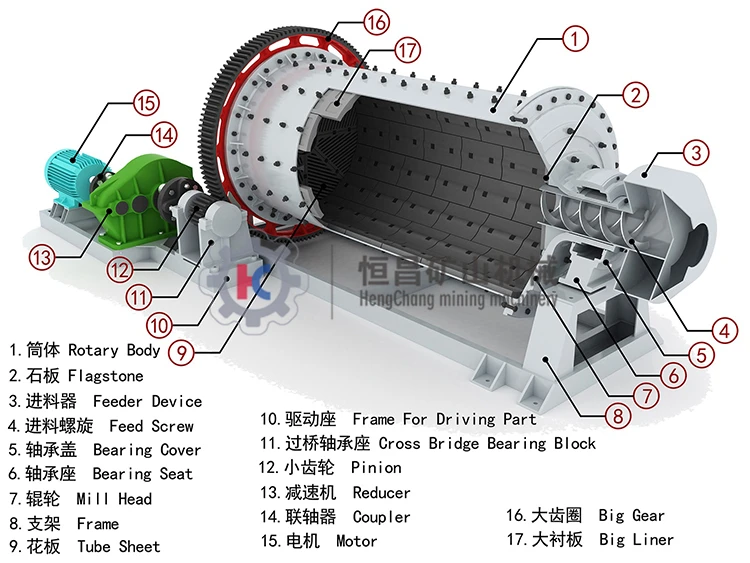

Gold Mining Equipment Introduction:

Gold Mining Equipment is a key equipment to grind the crushed materials, and the Gold Ball Mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grid type and overflow type due to different ways of discharging material.

Gold Mining Equipment Working Principle:

Gold Mining Equipment is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Gold Mining Equipment Applications:

Gold Mining Equipment is mainly used to grind materials in mineral, cement, refractory, chemical industry etc. Ball mill has dry and wet ways. When wet ball mill works, certain water and other liquid will be added into materials to increase flow ability of materials, so the capacity is increased. When dry ball mill works, capacity is affected because material flow ability is reduced, so absorbing wind device is needed on the outlet of ball mill, and then negative pressure is formed in the ball mill to increase flow ability of material, so the capacity is increased etc.

Model | Revolution | Balls | Max size | Capacity | Power | Dimension | Weight |

r/min | t | mm | t/h | kw | (LxWxH)mm | kg | |

GM0912 | 41.6 | 1.1 | 25 | 0.3-0.9 | 11 | 3843*1850*1400 | 4210 |

GM0921 | 41.6 | 1.8 | 25 | 0.6-1.5 | 15 | 4743*1850*1400 | 6660 |

GM0933 | 41.6 | 2.8 | 25 | 0.9-2.3 | 30 | 5943*1850*1400 | 7770 |

GM1224 | 35.1 | 4.0 | 25 | 1.6-4.1 | 37 | 5540*2300*1850 | 10020 |

GM1232 | 35.1 | 5.3 | 25 | 2.2-5.5 | 45 | 6340*2300*1850 | 11230 |

GM1244 | 35.1 | 7.3 | 25 | 3.0-7.5 | 55 | 7540*2300*1850 | 13210 |

GM1324 | 30.2 | 4.5 | 25 | 1.5-3.5 | 37 | 5035*2370*1880 | 10210 |

GM1334 | 30.2 | 6.5 | 25 | 2.2-5.0 | 75 | 6035*2370*1880 | 13117 |

GM1524 | 30.7 | 7.0 | 25 | 2.8-6.5 | 55 | 6830*2930*2060 | 15430 |

GM1530 | 30.7 | 9.0 | 25 | 3.5-8.0 | 80 | 7430*2930*2060 | 16843 |

GM1536 | 30.7 | 11.0 | 25 | 4.5-10.0 | 95 | 8030*2930*2060 | 18649 |

GM1545 | 30.7 | 13.5 | 25 | 5.5-13.5 | 110 | 8930*2930*2060 | 20000 |

GM1830 | 25.04 | 13.0 | 25 | 3.0-17.0 | 130 | 9525*3960*2250 | 29490 |

GM1836 | 25.04 | 15.0 | 25 | 4.0-21.5 | 155 | 10125*3960*2250 | 31600 |

GM1844 | 25.04 | 19.0 | 25 | 5.2-26.0 | 180 | 10925*3960*2250 | 34210 |

GM1864 | 25.04 | 27.0 | 25 | 8.0-40.0 | 210 | 12925*3960*2250 | 42440 |

GM2130 | 23.8 | 20.0 | 25 | 4.0-30.0 | 180 | 8475*4060*3400 | 41965 |

GM2145 | 23.8 | 25.0 | 25 | 5.6-42.0 | 280 | 9975*4060*3400 | 49230 |

GM3245 | 18.7 | 65.0 | 25 | 100-145 | 630 | 13000*7200*5700 | 145000 |