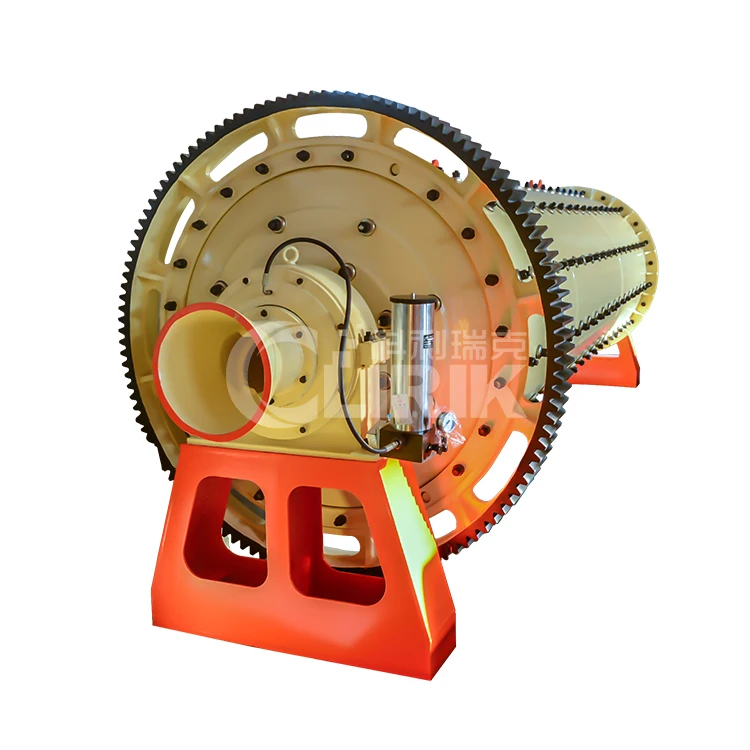

Large Capacity Industrial Continuous Gold Ore Limestone Ball Mill Grinder with Classifier

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Gearbox, motor, Gear |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1-350 |

| Place of Origin | Shanghai |

| Brand Name | Clirik |

| Dimension(L*W*H) | according to your model |

| Weight | 4600 KG, 4.6t-260t |

| Warranty | 1 Year |

| Color | Customizable |

| Usage | 10-15 Years |

| Product name | Ball Mill |

| Installation | Engineer's Guide |

| Factory Visit | Welcomed Warmly |

| Max feeding size | mm |

| Market | Global |

| Application | Stone Powder Grinding |

| Spare parts supplying | Service Life |

Product Detail

Large Capacity Industrial Continuous Gold Ore Limestone Ball Mill Grinder with Classifier

*every production line needed machines are difference*

*the final quotation will according to your project case*

Introduction of Ball Mill

Raw materials: quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, total about 400 kinds of materials.

Capacity: 20-200t/h

Max feeding size: 25mm

Application: suitable for processing various non-flammable and non-explosive mineral materials with Moh's hardness less than 9.3 and humidity less than 6%, it is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc

Shipping ports: Shanghai, China

Delivery: 15 days after received the deposit

|

Model |

Rotary speed (r/min) |

weight (t) |

Input size (mm) |

Discharge size (mm) |

Capacity (t/h) |

Motor power (kw) |

Weight (t) |

|

Ball Mill 900*1800 |

39 |

1.5 |

≤20 |

0.075-0.89 |

0.8-2 |

18.5 |

4.6 |

|

Ball Mill 900*1800 |

39 |

2.7 |

≤20 |

0.075-0.89 |

1-4 |

22 |

5.6 |

|

Ball Mill 1200*3000 |

36 |

3.5 |

≤25 |

0.074-0.4 |

1.6-5 |

37 |

12.8 |

|

Ball Mill 1200*4500 |

32 |

5 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

13.8 |

|

Ball Mill 1500*3000 |

27 |

7.5 |

≤25 |

0.074-0.4 |

2-5 |

75 |

15.6 |

|

Ball Mill 1500*5700 |

28 |

12 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

24.7 |

|

Ball Mill 1830*3000 |

25 |

11 |

≤25 |

0.074-0.4 |

4-10 |

130 |

28 |

|

Ball Mill 1830*6400 |

24 |

21 |

≤25 |

0.074-0.4 |

7-16 |

210 |

34 |

|

Ball Mill 1830*7000 |

24 |

23 |

≤25 |

0.074-0.4 |

8-18 |

245 |

36 |

|

Ball Mill 2100*3600 |

23 |

19 |

≤25 |

0.074-0.4 |

10-36 |

210 |

46 |

|

Ball Mill 2200*4500 |

21 |

27 |

≤25 |

0.074-0.4 |

12-23 |

280 |

48.5 |

|

Ball Mill 2200*6500 |

21 |

35 |

≤25 |

0.074-0.4 |

14-26 |

380 |

52.8 |

|

Ball Mill 2200*7000 |

21 |

35 |

≤25 |

0.074-0.4 |

15-28 |

380 |

54 |

|

Ball Mill 2200*7500 |

21 |

35 |

≤25 |

0.074-0.4 |

15-30 |

380 |

56 |

|

Ball Mill 2400*4500 |

21 |

30 |

≤25 |

0.074-0.4 |

18-45 |

320 |

65 |

|

Ball Mill 2400*8000 |

20 |

36 |

≤25 |

0.074-0.4 |

20-48 |

410 |

81 |

|

Ball Mill 2700*3600 |

21 |

39 |

≤25 |

0.074-0.4 |

19-75 |

400 |

83 |

|

Ball Mill 2700*4000 |

20 |

40 |

≤25 |

0.074-0.4 |

20-78 |

400 |

85 |

|

Ball Mill 2700*4500 |

20 |

48 |

≤25 |

0.074-0.4 |

22-85 |

430 |

89 |

|

Ball Mill 3200*4500 |

18 |

65 |

≤25 |

0.074-0.4 |

29-140 |

800 |

137 |

|

Ball Mill 3200*5400 |

18 |

81.6 |

≤25 |

0.074-0.4 |

30-180 |

800-1000 |

146 |

|

Ball Mill 3600*4500 |

17 |

88 |

≤25 |

0.074-0.4 |

35-210 |

1000 |

190 |

|

Ball Mill 3600*6000 |

17 |

117 |

≤25 |

0.074-0.4 |

38-240 |

1250-1500 |

220 |

|

Ball Mill 3600*8500 |

17 |

144 |

≤25 |

0.074-0.4 |

45-260 |

1800 |

260 |

Features of Ball Mill

1. Suitable for grinding material with high hardness

2. The shape of the final products is circular

3. No pollution for the powder with ceramic ball

4. Stable performance

5. Easy installation

6. The capacity and fineness can be adjusted by adjusting the diameter of the ball

Working Principle of Ball Mill

Ball Mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Ball Mill machine changes the intrinsic grinding mill structure. Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only. Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%. The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.

Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Clirik Ball Mill Certification

We are adhering to innovation,quality assurance,customer-oriented principle,and the introduction of a large number of highly qualified technical personnel,making the company after years of development fromed a professional ball mill production system received CE certification and other qualifications.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

If you are interested in other mining machine, you are welcome to visit our

-----Related Products-----

|

|

|

|

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Ball Mill Manufacturer---Shanghai Clirik Machinery CO., LTD

Shanghai Clirik Machinery CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, European version coarse grinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on.

Specially we independently developed HGM ultra fine grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc. We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front.

Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment, optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.

Clirik Factory

Clirik Working Site

Clirik Sales Team

Clirik Team Building

Clirik Attended Exhibition

Clirik Customers Visit

Clirik Customer Site

Clirik Service

Pre-Sales Service

♥ Online interactive service

♥ Offline interactive service

♥ Solution design service

♥ Visit reception service

After-Sales Service

♥ Installation and debugging service

♥ Training service

♥ Other more service(Clients have any needs or problems; our engineer can take plane and get the worksite to provide service in 48 hours.)

FAQ

1. who are we?---

We are based in Shanghai, China, start from 2010,sell to Mid East(30.00%),Africa(20.00%),Southeast Asia(19.00%),South Asia(15.00%),North America(3.00%),South America(3.00%),Domestic Market(3.00%),Southern Europe(2.00%),Eastern Europe(00.00%),Eastern Asia(00.00%),Western Europe(00.00%),Central America(00.00%),Northern Europe(00.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?---

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?---

Ball Mill, crusher and other needed machines in the stone powder production line project

4. why should you buy from us not from other suppliers?---

1. CE, ISO9001

2. factory sell directly

3. 30 years experience, professional

4. Sales market all over the world

5. good after sales serive

5. what services can we provide?---

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,French

Shanghai Clirik Machinery CO., LTD

You are welcome to leave your inquiry to us here ⇓⇓⇓