Low Cost 4Tph High Performance 5R Raymond Mill Process Basalt Stone Dolomite Calcium Powder Mill

US $21,000.00-22,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Engine, Bearing, motor, Gearbox

Type:

Raymond Mill

Motor Type:

AC Motor

Capacity(t/h):

3-5

Privacy Policy:

Samples are free within a certain price range

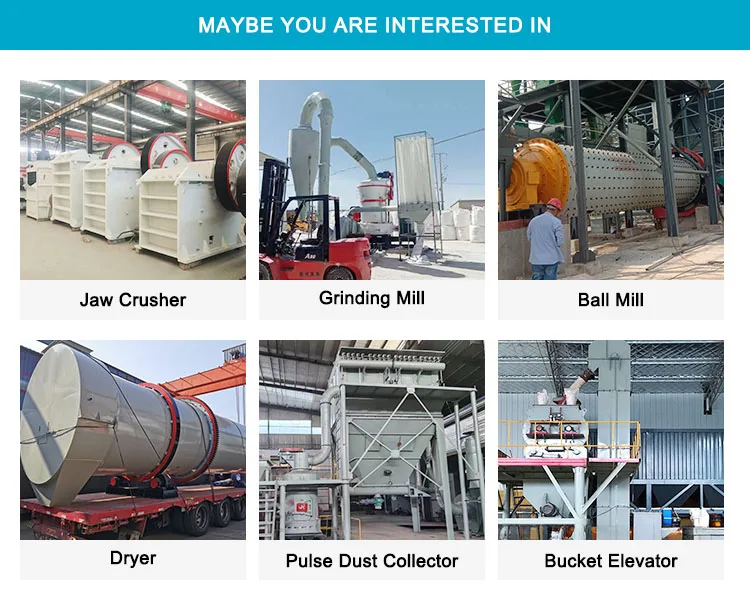

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, motor, Gearbox |

| Type | Raymond Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 3-5 |

| Place of Origin | Henan, China |

| Brand Name | Kolev |

| Weight | 148000 KG |

| Warranty | 1 Year |

Product Detail

Low Cost 4Tph High Performance 5R Raymond Mill Process Basalt Stone Dolomite Calcium Powder Mill

The Raymond grinding mill is widely used in such small and medium industries as metallurgy, building materials, chemical, mining,refractories, pharmaceuticals, cement, etc.It can be used in grinding of limestone, calcium carbonate, gypsum, barite, calcite, feldspar, talc, talcum, marble, ceramic, dolomite, zeolite, quartz stone, silica, carbonate, iron ore, slag, bauxite, clay, bentonite, carborundum, charcoal, phosphate rock , coal , petroleum coke, graphite, glass etc.

Feature | ||

1 | Higher capacity under samedriving force, | |

2 | Adjustable powder size andfiner products granularity and a sieving rate of 99% | |

3 | The important parts are all made of steel, wear-resistant parts use high-performance wear-resistant materials. | |

4 | Three-dimensional structure, land-saving and independent production system. | |

5 | The electrical system adopts centralized control, simple operation. | |

6 | Convenient maintenance,reliable air tightness and gooddust removal effect; | |

The whole raymond grinding mill machine is collocated with jaw crusher, elevator, hopper,electromagnetic vibrating feeder, main unit, classifier, collector, cloth deduster and high-pressure blower.

Load the stuff for grinding evenly and continuously into the grinding chamber of the main frame. Due to the centrifugal force in rotation, the roller swings go outward and presses closely upon the ring. The shovel carries the stuff to the space between the roller and ring. When the roller rolls, the stuff is thus grinded. After being grinded, the stuff is to be routed to the classifier along wind belt of the blower and the rough powder will be put back to the grinder for regrinding. When the particle size is up to the required flow into the cyclone collector, the finished product is discharged through the powder outlet tube after collection.

12 months warranty for all kinds of products. We will supply the wear parts with factory price .

Model | KL500 | KL650 | KL780 | KL980 | KL1100 | KL1450 | KL1780 | KL1950 | KL2100 | ||||||||

Capacity(t/h) | 0.5-2 | 0.5-2.5 | 1-3 | 1.5-4 | 2-6 | 6-10 | 8-20 | 15-30 | 20-40 | ||||||||

Main engine motor power(kw) | 7.5 | 15 | 18.5 | 30 | 45 | 90 | 132 | 185 | 220 | ||||||||

Fan motor power(kw) | 5.5. | 11 | 15 | 22 | 45 | 100 | 160 | 185 | 220 | ||||||||

Analyzer motor power(kw) | 1.1 | 120 | 2.2 | 2.2 | 5.5 | 7.5 | 22 | 37 | 45 | ||||||||

Main shaft speed(r/m) | 120 | 120 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | ||||||||

Diameter of Grinding ring(mm) | 500 | 650 | 780 | 980 | 1100 | 1450 | 1760 | 1950 | 2100 | ||||||||

Diameter of grinding roller(mm) | 150 | 180 | 260 | 300 | 320 | 400 | 450 | 570 | 630 | ||||||||

max.feed size(mm) | 15 | 15 | 15 | 20 | 25 | 30 | 30 | 40 | 40 | ||||||||

Final size(mm) | ≥0.023 | ||||||||||||||||

Weight(t) | 1.8 | 2.8 | 3.8 | 6.5 | 14.5 | 26 | 48 | 65 | 85 | ||||||||

Q1: Are you factory or trade company? |

A1: We are factory with CE. |

Q2: How long is your delivery time? |

A2:7-10 days for the stock, 15-30 days for the mass production. |

Q3: How will you help the customer to install the equipment? |

Our senior engineer will supply installation and training service on-line or on-site. |

Q4: How about the wear parts supply? |

A4: We will supply the wear parts with factory price . |

Q5: What about after-sale service? |

A5:12 months warranty for all kinds of products. |

Q6: How to get the free solution and quotation ? |

A6: Please send inquiry to us ,leave your whatsapp and email , our sales manager will contact you within 1 hours |